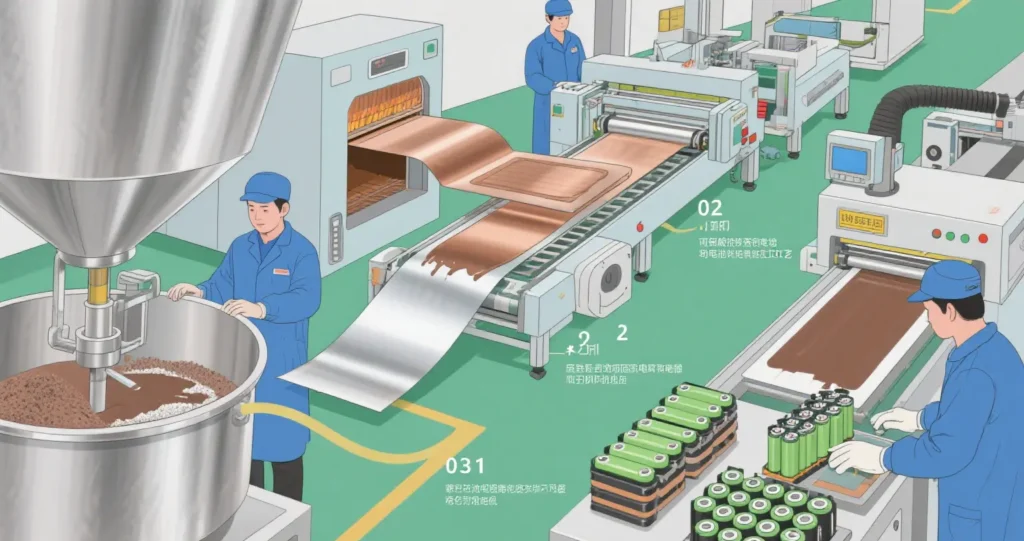

2005 lithium battery manufacturing core pretreatment process experience sharing

Lithium battery manufacturing cell pretreatment is the core first process of lithium battery Pack manufacturing, and its process level directly determines the range consistency of new energy vehicles and the cycle life of the energy storage system. Through systematic testing and precise sorting, the process eliminates the inherent performance dispersion of mass-produced battery cells and lays the foundation for module integration and system reliability. In this article, we will share in-depth experience on the pre-treatment process of lithium battery cells manufactured in 2005.

The necessity of lithium battery manufacturing pretreatment: to solve the inherent dispersion of the core

Even with the same materials and processes, the batch output of lithium battery cells still have an inevitable performance distribution:

- Capacity fluctuation: ±3% (resulting in vehicle range difference >50km)

- Internal resistance dispersion: 5% (affecting charging/discharging efficiency and thermal balance)

- Voltage deviation: >0.05V (resulting in BMS regulation misalignment)

Such microscopic differences will trigger the “barrel effect” at the macro level:

- The actual capacity of the battery pack is limited by the weakest cell.

- Inconsistency leads to localized overcharging/overdischarging (capacity loss up to 15%).

- Accelerates the difference in cell degradation, shortening the life of the system by more than 30%.

Pre-processing three major technology links

1. Appearance and Physical Characteristics Inspection

Adopt “machine vision + plasma processing” dual-track system:

CCD automatic detection:

- Aluminum shell variance <0.1mm

- Explosion-proof valve integrity verification

- Electrolyte leakage detection (sensitivity 1ppm)

Plasma activation:

- Processing power: 1000-1500W

- Surface tension upgraded to 72mN/m (original value 38mN/m)

- PET film roughness Ra from 0.2μm to 1.5μm

2. Electrochemical parameter testing

Constructed high precision test matrix (accuracy required):

| parameters | Testing methods | Equipment accuracy | qualification criteria |

|---|---|---|---|

| open circuit voltage | Four-wire measurement method | ±0.1mV | 3.0V-4.2V |

| AC internal resistance | 1 kHz impedance analysis | ±0.5mΩ | ≤50mΩ(power cell) |

| DC internal resistance | 10s@1C pulse | ±1mΩ | ≤55mΩ |

The test process strictly follows:

material positioning → code scanning traceability → voltage/internal resistance synchronized test → NG product isolation → data upload MES

3. Capacitated grouping strategy

Realize cell synergy through multi-dimensional parameter matching:

- Capacity grouping: ±1% tolerance interval (0.5Ah staging)

- Voltage matching: ≤5mV intra-group polarity difference

- Internal resistance control: ≤3mΩ dynamic deviation

- Advanced sorting technology:

- Dynamic characteristic curve analysis (0.2C/0.5C/1C multiplicity)

- Electrochemical Impedance Spectroscopy (EIS) phase angle matching

Process control points

- Environmental control: dew point ≤ -40℃ dry room (prevent lithium dendrite growth)

- Data traceability: full life cycle data chain of electric core (20 years traceable)

- Equipment calibration: daily standard calibration (±0.05% accuracy)

Measured data shows that the cycle life of the battery pack after strict pretreatment is increased by 40%, and the capacity utilization rate reaches more than 95%.

Core pretreatment has become a high-quality lithium battery manufacturing technology barriers, and its accuracy directly determines the competitiveness of end products. With the development of solid-state battery technology, the pretreatment process will further integrate material characterization and non-destructive testing technology to build a smarter consistency control system for battery cells.