2025 Drone Battery Buying Guide

When the plant protection drone suddenly drops 15% power in 45℃ high temperature, you will understand – the consistency of the drone battery cell is 100 times more important than the capacity figure.

Law 1: Drone battery cell quality – the life and death of the energy heart

1. Cycle life: a hard indicator for thousands of jumps

Industrial-grade UAV battery: ≥500 cycles (capacity retention >80%)

Cutting-edge choice: lithium iron phosphate (LFP) system

Advantage:

UAV battery high-temperature tolerance: capacity degradation at 60°C <5% (Li-ion ternary >20%)

Cycle life: 1500 cycles @25°C measured by Far East Battery

Drone battery limitations: energy density 160Wh/kg → range reduction of 15%, but stability crushing

2. Cell consistency: invisible killer

Voltage polarity >50mV → 300% risk of bulging (Synventive lab data)

Means of detection:

A, full power static 1h –> Measurement of individual voltage –> Polarization ≤ 30mV? -> Yes: qualified

B, full power static 1h –> Measurement of individual voltage –> Polarization ≤ 30mV? -> No: scrapped batch

3. China’s Solid State Battery Breakthrough Direction:

Ningde Times cohesive electrolyte technology:

Increase cycle life by 200% at high temperature 70℃

0 fire in puncture test (traditional LFP > 120℃ thermal runaway)

Law 2: Drone Battery Discharge Performance – The Steel Backbone of Heavy Duty Flight

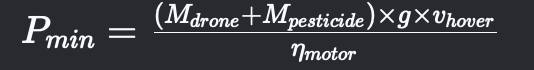

Plant protection drone energy requirement formula:

(v hovering = 5 m/s, η motor efficiency ≈ 0.7)

Key parameter anchor points:

| payloads | Minimum continuous discharge rate | Instantaneous peak requirements |

|---|---|---|

| 10kg | 10C | 15C(3s) |

| 20kg | 15C | 25C(3s) |

Blood tears lesson:

- A 16kg payload UAV chooses 8C battery → takeoff voltage drop>1V → trigger ESC protection to blow up

- Solution: Ganfeng lithium solid-state battery supports 20C pulse discharge (-20℃ no attenuation)

Law 3: Safety Systems – Survival in High Temperature and High Humidity Environments

BMS triple protection barriers:

(1) Voltage monitoring:

- Over-voltage protection ≥4.25V/cell (LFP: 3.65V)

- Under-voltage protection ≤3.0V/cell (to prevent over-discharge damage)

(2) Thermal management engine:

- > 60 ℃ forced power reduction → Far East Battery patented phase change material temperature control

- <-20 ℃ to start self-heating (China’s solid-state battery low temperature advantage)

(3) Communication protocol:

- CAN bus real-time backhaul SOC/SOH → DJI Agras T40 standard.

Mechanical protection standard:

- IP54:

- basic dustproof and waterproof (light rain operation)

- Upgrade program:

- Silicone potting process → pesticide corrosion resistant

- Carbon fiber shell → 30% weight reduction + impact resistance

2025 Technology Foresight: China’s solid-state batteries for drones strike a downward spiral

Agricultural drone pain point end solution:

| point of pain | traditional approach | Solid-state battery breakthrough |

|---|---|---|

| high-temperature attenuation | Restricted working hours | 80°C cycle life ↑300% |

| charging efficiency | 2-hour slow charging | Ningde 5C fast charging (12 minutes full charge) |

| Low-temperature endurance | -10°C capacity halved | Discharge retention rate at -40°C > 85% |

Operation Recommendation:

Give priority to batteries equipped with the following technologies:

- 1. intelligent equalization BMS (single voltage difference <20mV)

- 2. Support fast charging above 4C (matching PV charging pile)

- 3. China solid-state battery pre-built interface (upgraded and compatible in 2025)

In the plant protection battlefield, battery is not a consumable but a production tool. Choosing an energy solution that matches the consistency of the battery cell + discharge multiplier + intelligent BMS iron triangle, in order to make the harvest of ten thousand acres of good fields no longer ruined by an accidental power dive.