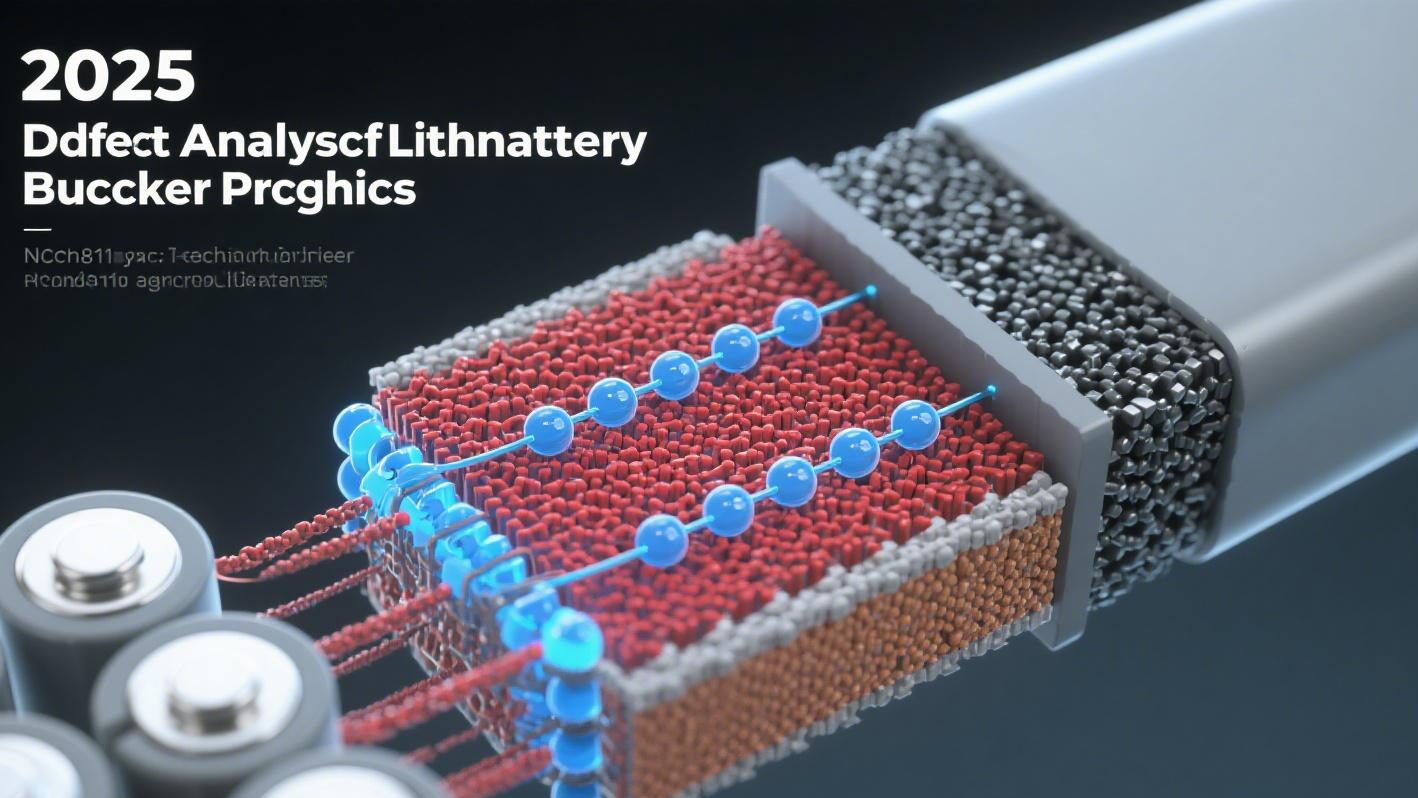

2025 In-depth analysis of the working principle of lithium battery

I. Lithium battery charging process: the long march of lithium ion

1. Lithium battery anode de-embedding: the starting point of energy activation

Electric field drive: external voltage is applied → lithium ion is energized to get out of the anode laminar structure (e.g. LiCoO₂)

Electron transfer: electrons flow to the negative electrode through the external circuit, and lithium ion opens up the solid-phase diffusion (diffusion coefficient ≈ 10-¹⁴ m²/s)

2. Li-ion battery CEI membrane: guarding barrier for positive electrode

| Ingredients | function | technological breakthrough |

|---|---|---|

| Lithium phosphate (Li₃PO₄) | Building an ion channel framework | Chinese team optimizes crystallinity to improve conductivity |

| polymer | Reduce interface impedance | BYD’s patented additive reduces resistance by 30% |

| lithium salt derivatives | Inhibition of transition metal dissolution | CATL’s nano-coating technology |

Engineer’s warning: Uneven growth of CEI film leads to localized overfilling, controlling thickness <5nm is key

3. Electrolyte migration: the dance of the solvated sheaths

Diffusion rate equation:

v = \frac{D \cdot \Delta C}{\eta \cdot d}

(D: diffusion coefficient, η: viscosity, d: migration distance)

Temperature sensitivity: 300% surge in electrolyte viscosity at -20°C → ion migration rate plummets

4. SEI membrane formation: the lifeblood of the negative electrode

First charge reduction reaction:

2EC + 2e- + 2Li⁺ → (CH₂OCO₂Li)₂ + C₂H₄

Core Functions:

- Electronic insulator (resistivity > 10⁹ Ω-cm)

- Lithium-ion conductor (conductivity ≈ 10-⁸ S/cm)

- Inhibition of solvent co-embedding (graphite swelling <10%)

5. Desolventization: the life and death of fast charging

Energy barrier: 0.5-1.2eV barrier to be overcome to remove solvent molecules

Breakthrough solution:

- Electrolyte design: add FEC to reduce desolvation energy (Azalea 150kWh semi-solid state battery)

- Negative electrode modification: gradient doping on hard carbon surface (CNA patent)

6. Graphite embedding: microstructure wars

| question | consequences | solutions |

|---|---|---|

| LiC₆ phase change stress | Graphite interlayer spacing from 3.35Å to 3.7Å | Honeycomb Energy Multi-level Pore Design |

| dislocation accumulation | Accelerated capacity degradation | Bettery Pre-Lithiation Technology |

| SEI rupture regeneration | Continuous consumption of active lithium | Add LiDFOB self-healing additive |

II. Discharge process: precise control of energy release

1. Three laws of reverse migration

(1)Electric field reversal:

electrons flow back to the positive electrode through the external circuit (current density ≈ 20mA/cm²)

(2)Concentration gradient drive:

anode lithium ion concentration > positive electrode → diffusion pressure difference formation

(3)Solvation re-assistance:

EC/EMC solvent recombination transport sheaths

2. Core regulatory parameters of the BMS

| parameters | reasonable range | risk of losing control |

|---|---|---|

| temperature | 15-35℃ | <-10℃ lithium deposition|>45℃ SEI decomposition |

| discharge rate | <1C (power cell) | >3C causes concentration polarization |

| cut-off voltage | 3.0V±0.1V | <2.8V causes copper foil dissolution |

3. Energy barrier breakthrough in anode embedding

- Layered material: Li⁺ embedding channel diameter ≈ 2.8Å (requires stripping of solvent sheath)

- Spinel structure: 3D diffusion path reduces resistance by 50% (Ningde Times LiFeMn program)

IV.Future Interface Engineering: China’s Solid State Battery Breaking Points

1. Electrolyte Innovation

- Phoenitronics: In-situ polymerized interface layer → 87% reduction in solid-solid contact impedance

- Tsing Tao Energy: LLZO/LATP composite electrolyte → room temperature conductivity up to 6.3mS/cm

2. Bionic SEI design

- Ganfeng Lithium: Artificial SEI membrane (LiF/Li₃N gradient layer) → Cycle life increased to 2000 cycles

- Theoretical breakthrough: Institute of Physics, Chinese Academy of Sciences reveals SEI dynamic evolution mechanism (Science 2025)

Conclusion: Working Principle Determines Performance Ceiling

When the de-solvation energy barrier is depressed by FEC additives by 0.3eV, when artificial SEI keeps lithium losses to 0.5nAh/cycle – every evolution of the lithium battery is a deeper taming of the laws of ion migration.

The ultimate law:

\eta_{cell} = \frac{\text{actual discharge energy}}{\text{theoretical chemical energy}} = f(\text{interface engineering}, \text{material design}, \text{BMS accuracy})

(Battery efficiency as a function of three major technical variables)

As a cell design engineer, I am a firm believer that there is no such thing as a perfect chemical system, only engineering ingenuity that keeps pushing the physical limits. The Chinese team’s innovations are compressing lithium ion migration loss from 15% to 5% – that 10% gap is the battleground for the next generation of batteries.