2025 Li-ion battery auricle redundancy design

Li-ion battery lug redundancy design is directly related to the safety and reliability of lithium batteries, and is a key consideration in battery engineering.

As lithium battery engineers, we are well aware of the critical importance of the design of lithium battery electrode lugs to the performance and safety of the battery. As the only connection channel between the internal and external circuits of the battery, the redundancy design of the lugs not only affects the current transfer efficiency, but also directly relates to the safety performance and cycle life of the battery.

In this paper, we will systematically analyze the key factors affecting the redundant design of lithium battery lugs, and propose corresponding solutions from an engineering perspective to provide professional reference for battery design and manufacturing.

I. The nature and importance of lithium battery lug redundancy

Lithium battery lug redundancy refers to the battery design and manufacturing process, in order to ensure that the lugs in a variety of operating conditions and reliable connection of the extra length, area or structure design. This design is not simply “extra material”, but a precisely calculated safety buffer and performance guarantee.

Reasonable lug redundancy design of Li-ion batteries can cope with a variety of complex situations:

- Adapting to different cell sizes and packages

- Compensating for unavoidable fluctuations and deviations in the manufacturing process

- Coping with deformation caused by cyclic charging/discharging and temperature changes during use

- Providing safety redundancy and buying time for protection mechanisms in extreme situations

II. Li-ion Battery Design Adaptability Factors and Engineering Solutions

Matching cell size to package design

Different cell types have very different requirements for lug redundancy:

Flexible cells typically require more redundancy to fit the encapsulation margins. The aluminum-plastic film encapsulation process requires adequate sealing margins, which requires sufficient lug length to ensure reliable connections after encapsulation. It is generally recommended to allow for an additional 2-3mm of length to accommodate positional deviations during the encapsulation process.

Cylindrical and square cells require matching shell soldering space. As cell size increases, so does the amount of lug redundancy required. For example, the 4680 Large Cylindrical Cell requires more lug welding and connections due to its full lug design.

Table: Lug Redundancy Design Requirements for Different Cell Types

| Cell Type | Typical Redundancy Requirements | Key considerations | solution |

|---|---|---|---|

| Soft pack battery cells | 2-3mm length redundancy | Package Margin Matching | Increase the length of the lugs |

| Cylindrical Cells | Angular Adaptive Redundancy | Welding space matching | Optimized auricle shape |

| Square Cells | Area redundancy | Structural strength requirements | Increase lug thickness |

Optimized selection of material and thickness of lithium battery lugs

The choice of lug material has a direct impact on the redundancy design:

Copper lugs have excellent electrical conductivity but relatively low ductility, requiring more redundancy to avoid bending and breaking. Aluminum lugs are lightweight and low-cost but mechanically weak, requiring increased thickness or area redundancy. Composite lugs (e.g., copper-aluminum transition lugs) combine the advantages of both materials, but require special redundancy at the joint.

The thickness of the lugs also needs to be carefully chosen: thicker lugs have good mechanical strength but are prone to stress concentrations when bending, requiring increased bending radius redundancy; thin lugs need to balance redundancy and conductive efficiency to avoid increased resistance due to excessive length.

Precise Calculation of Current Density Requirements

High-rate discharge batteries place special demands on the design of the lugs:

- In high-magnification applications, the lugs need to withstand extremely high current densities. Insufficient redundancy can lead to a concentration of current, triggering localized overheating. Theoretically, the current density should be kept within safe limits (typically <10A/mm² for copper lugs and <6A/mm² for aluminum lugs).

- For high-performance applications such as custom drone battery packs, the design of the lug redundancy requires special consideration of the peak current demand. By increasing the width of the lugs or using a multi-layer lug structure, the current density can be effectively reduced and the heat dissipation improved.

III. Production process fluctuation factors and quality control

Compensation strategy for welding accuracy deviation

Welding process is one of the most critical aspects in lug manufacturing:

- Welding position deviations between lugs and collectors, and lugs and poles, are a common problem, and even a deviation of 0.1-0.3 mm may affect the weld quality. For this reason, the lugs need a sufficient amount of redundancy to cover this deviation.

- Modern battery factories use laser welding and ultrasonic welding technology, together with high-precision vision positioning systems, to control welding accuracy to within ±0.05mm. But even so, a redundancy of 0.5-1mm still needs to be set aside to ensure welding reliability.

Control Measures for Cutting and Molding Errors

The precision of lug cutting directly affects the quality of the subsequent process:

- Cutting tolerances are usually within ±0.05mm, and bending angle deviations are less than 1°. To compensate for these errors, a redundancy of 0.2-0.5mm in the length direction of the lugs is required.

- Advanced gradient laser die-cutting technology can accurately control the height of each layer of lugs, fundamentally avoiding the risk of core insertion caused by lug redundancy.10 This technology accurately determines the ideal height of each layer of lugs by calculating parameters such as core thickness and cover distance.

Assurance Program for Alignment of Cell Assembly

Li-ion battery cell stacking or winding process lug alignment is critical:

- Slight misalignment of the lugs may prevent proper convergence into the poles, affecting the conductive path. Through rational redundancy design, the lugs can be reliably connected even if there is a 0.5-1mm misalignment.

- NDT’s latest patent reduces the risk of short-circuiting caused by the insertion of the electrode lugs into the transition section by installing an elastic component in the housing, while limiting the position of the electrode body to minimize damage to the electrode lugs caused by the movement of the electrode body.

IV. Reliability Factors and Safety Design

Cyclic charging and discharging deformation response strategy

Lithium batteries expand and contract during cyclic charging and discharging:

This deformation creates a constant pulling force on the lugs. Polar lugs without sufficient redundancy may break or detach from the collector as a result. Studies have shown that lithium iron phosphate batteries increase in thickness by approximately 2-3% after 100 cycles, while ternary batteries may increase by 4-6%.

Ear redundancy designs need to absorb this deformation, often by increasing the bending radius or using special bending structures. For example, a crease is formed at the root of the lug to allow the lugs to bend along a predetermined trajectory, avoiding the need for an inserted cell.

Solutions for the effects of temperature changes

Differences in thermal expansion coefficients of materials at high and low temperatures lead to stress concentrations:

The coefficients of thermal expansion of the lugs and the core material are different, and temperature changes can create internal stresses. This stress can lead to loose connections or structural failure of the lugs.

The effects of temperature changes can be mitigated by optimizing the material and structural design of the lugs. For example, selecting materials with matching coefficients of thermal expansion or adding temperature compensating structures allows the lugs to expand and contract freely during temperature changes, reducing stress buildup.

Innovative solutions for safe and redundant design

Safety protection in extreme situations is a key consideration in the design of the pole lugs:

Abnormal conditions such as overcharging and short-circuiting can lead to extremely high currents, which may cause lug ablation. Redundant lug design can buy time for safety protection mechanisms (e.g., fuses) to be triggered.

The latest design options include:

- Multiple lug construction: Auxiliary lugs are placed alongside the main lugs to divert excessive currents

- Intelligent material application: Temperature-sensitive materials are used to automatically disconnect in the event of overheating

- Resilient cushioning design: A resilient component reduces the risk of short-circuiting caused by insertion of lugs into a transition section

V. Development trend of pole ear redundancy optimization

Digital design and simulation technology

Digital twin technology is changing the design method of the pole ear:

By creating accurate mathematical models of the behavior of the lugs, engineers can simulate the performance of the lugs under different operating conditions in a virtual environment and optimize redundant design parameters. Gradient laser die-cutting is a typical application of digital design, which avoids the risk of coring due to redundancy by accurately calculating the height value of each layer of the lug.

New materials and processes

Innovative materials provide more options for lug design:

The application of new materials, such as nanocomposites and highly conductive polymers, is improving the electrical conductivity and mechanical properties of the lugs. At the same time, new processes such as laser processing and ultrasonic molding have greatly improved the precision and consistency of the processing of the electrode lugs.

Jiangsu Zhengli New Energy Battery Technology Co., Ltd. has developed the snap-together piece technology, which forms the lug group by closing the lugs and effectively avoids the risk of backward insertion of lugs due to excessive redundancy of the lug group.

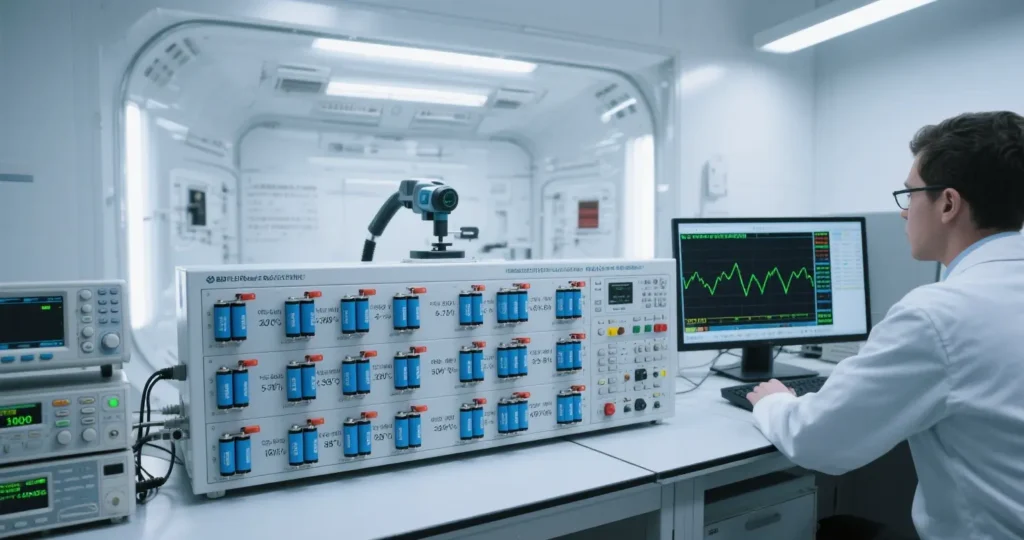

Intelligent Manufacturing and Quality Control

The application of artificial intelligence and machine learning technology in the manufacturing of electrode lugs:

Intelligent visual inspection system is able to recognize the defects of the electrode lugs in real time and adjust the process parameters automatically. Through big data analysis of quality data in the production process, the redundant design of the electrode lugs can be continuously optimized to improve product consistency and reliability.

VI. Recommendations for engineering practice

Based on the above analysis, we provide battery engineers with the following recommendations for redundant design of lithium battery lugs:

- 1. Fully understand the application requirements: According to the specific application scenarios of the battery (e.g. custom drone battery pack needs high multiplication performance), determine the current carrying requirements and safety standards of the lugs

- 2. Comprehensively consider the material properties: Select the appropriate lug material, balance the conductivity, mechanical strength and cost factors

- 3. Accurately calculate the redundancy parameters: Use methods such as gradient calculation 10. Accurately determine the ideal height and shape of each layer of lugs

- 4. Reserve space for process compensation: Considering the unavoidable deviations in the production process, reserve appropriate compensation redundancy

- 5. Test to verify the validity of the design: Verify the reliability of the redundant design of the lugs by means of cyclic testing, temperature shock testing, etc.

- 6. Continuously optimize and improve: Collect data from production and use, and continually improve the design of the lugs