2025 Lithium Battery Custom Development Guide

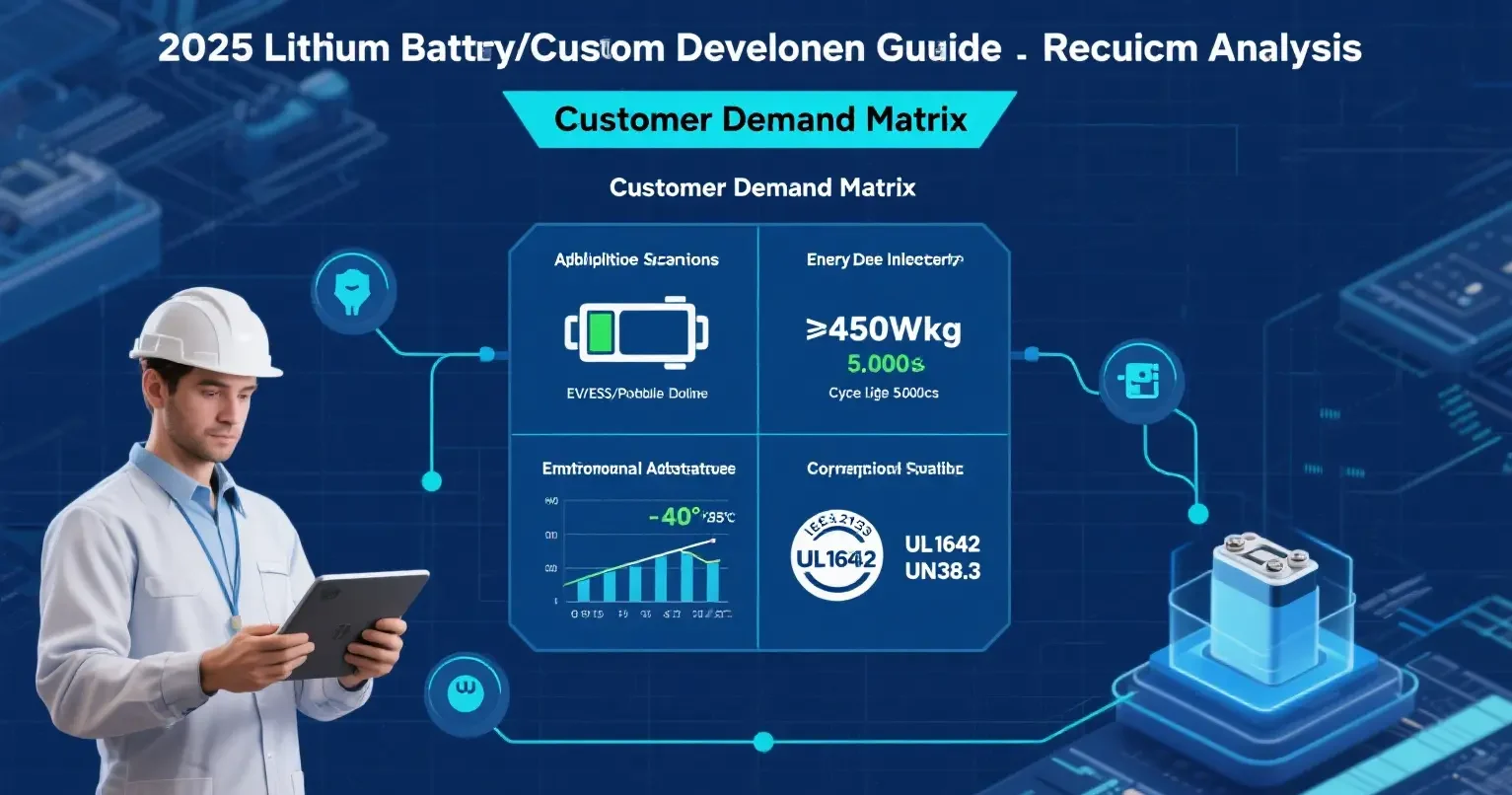

I. Definition of lithium battery customization requirements: precise anchoring of technical boundaries

The core of customized lithium battery is to accurately match the physical and electrochemical constraints of terminal application scenarios, and the following key parameters need to be clarified:

| Demand dimension | Engineering parameter definition | Application Scenario Cases |

|---|---|---|

| Energy/power characteristics | Energy type (Wh/kg priority) / Power type (C-rate ≥5C) / Balanced type | UAV: high rate discharge (>10C); energy storage: high volumetric energy density |

| environmental adaptation | Operating temperature range (e.g. -40℃~85℃), protection class (IP67/IP68), vibration resistance class (IEC 60068-2-64) | Construction machinery batteries need to meet 10G vibration resistance |

| structural constraints | 3D dimensional tolerance (±0.5 mm), shape freedom (curved/irregular), interface type (connector/pad) | Needed for medical devices Ultra-thin batteries (<3mm) |

| Safety certification | UN38.3, UL 2054, IEC 62133, GB 31241 (as required by mandatory regulations in the target market) | Exporting to Europe requires both CE and UKCA certification. |

Engineer’s Alert: Vague requirements are the main reason for customization failure! CAD drawings + charging/discharging condition spectrum (current/voltage/temperature timing) are required.

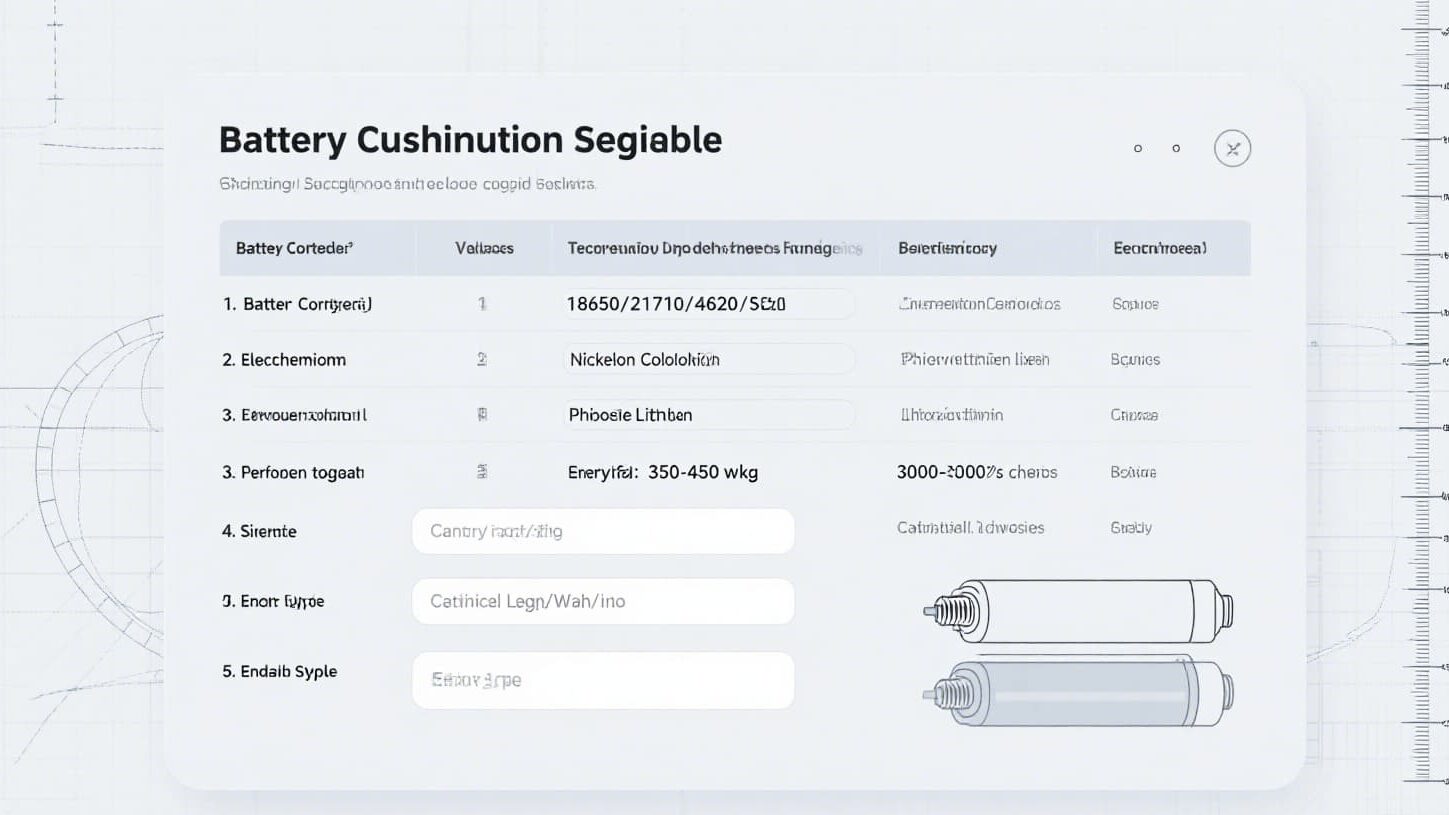

II. Technology program development: engineering game of material selection and structural design

1. Core level design

Chemical system selection:

High energy scenario: NCM811/Si-C system (energy density >280Wh/kg)

Low temperature scenario: LFP + low temperature electrolyte (-40℃ discharge retention rate >80%)

High power scenario: LTO anode + nanosized cathode (multiplier performance >15C)

Structural innovations:

Stacked (low internal resistance) vs. coiled (high space utilization)

Flexible electrodes (bending battery) vs. rigid shell (shock demand) Flexible Electrodes (Bendable Battery) vs Rigid Case (Vibration Resistant Requirements)

2. System level integration

Thermal management design:

Air-cooled (cost effective) / Liquid-cooled panels (homogeneous temperature ΔT<3C) / Phase change materials (transient thermal shock protection)

BMS safety redundancy:

Dual MCU architecture + millisecond fail-safe shutdown (response time <100μs)

Multi-dimensional safety valves (mechanically + electrochemically triggered)

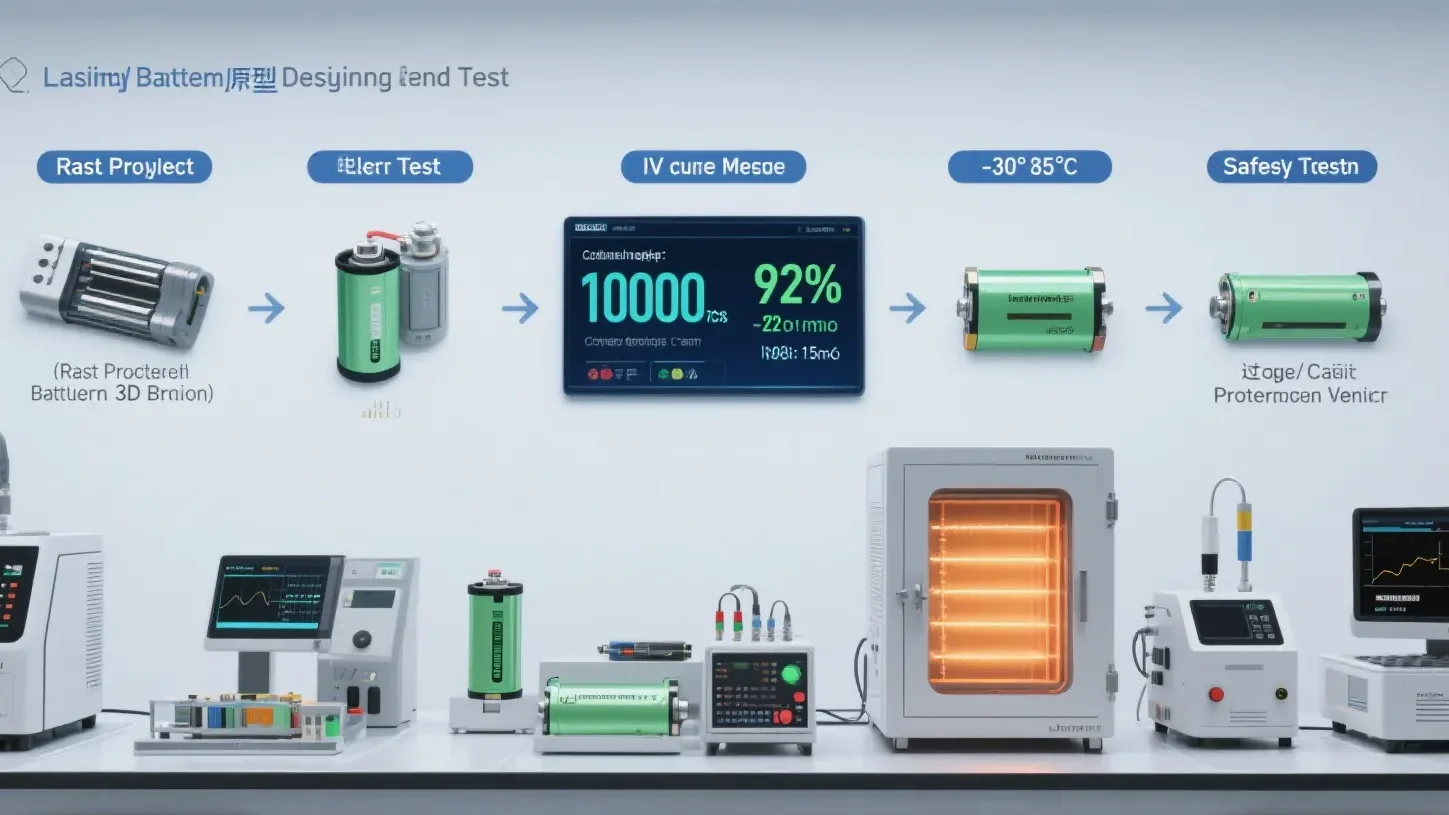

III. Prototype validation phase: 23 harsh tests to build safety barriers

Customized batteries must pass scenario-based extreme verification, and core test items include:

| Test category | Verification Project | Passed standards | engineering significance |

|---|---|---|---|

| Electrical performance verification | Multiplication discharge (10C pulse) | Voltage drop ≤10% | Confirm power output capacity |

| Environmental adaptability | -40°C low-temperature discharge | Capacity retention rate ≥75% | Verification of low-temperature conductivity of electrolyte |

| mechanical reliability | Random vibration (IEC 60068-2-64) | Internal resistance change ≤5%, no structural damage | Ensuring reliability in vehicle-mounted/unmanned aircraft scenarios |

| safety limit | Overcharge to 1.5 times the pressure limit | No fire, no explosion (GB 31241) | Testing BMS protection and material stability |

| abuse of security | Needle penetration test (Φ5mm steel needle) | Surface temperature ≤150°C, no thermal runaway | Evaluate the diaphragm’s resistance to internal short circuits |

Key deliverables: Test report to include EIS mapping (impedance comparison before and after cycling), thermal imaging data (charge/discharge temperature rise field).

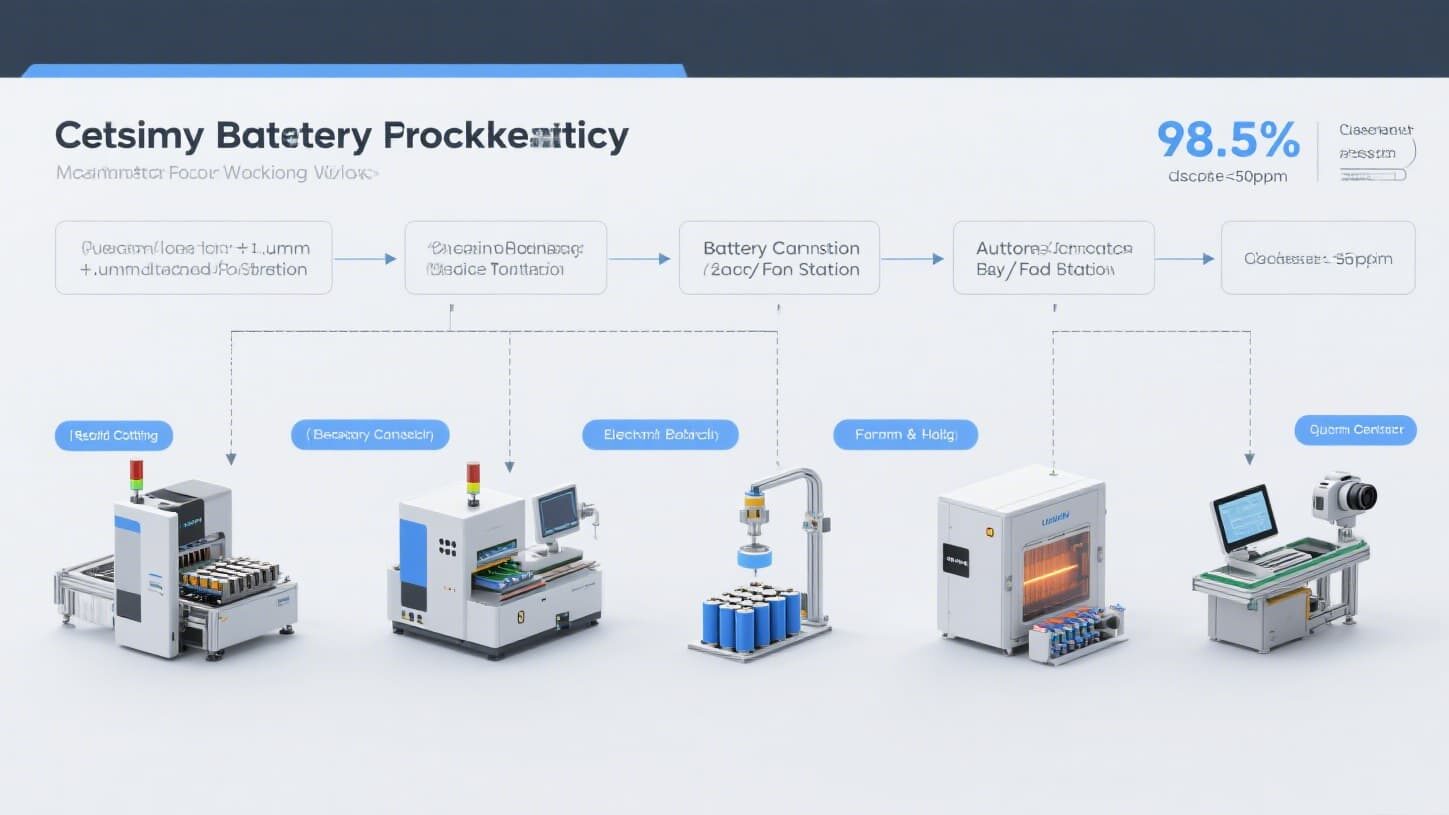

IV.Supply Chain Assessment: Manufacturing Capability Determines Mass Production Consistency

The following hard indicators should be examined when selecting cooperative manufacturers:

1. Material system control: Does

have core processes such as anode sintering and diaphragm coating?

Is the electrolyte formula self-developed or outsourced? (Customized electrolyte is required for low temperature/high voltage)

2. Guarantee of process precision:

Tolerance of surface density of electrode coating ≤±1.5%

Alignment precision of winding/stacking ≤±0.3mm

3. Quality system certification:

IATF 16949 (automotive grade necessary)

ISO 9001 + UL factory certification.

4. Mass production traceability:

MES system realizes core-level data traceability (e.g. laser coding DMC).

V. Engineers’ customized recommendations: avoiding common technical traps

1. Balance between energy density and life time:

Pursue >300Wh/kg, need to accept cycle life <800 times (NCM811 system)

Solution: Silicon carbon anode pre-lithiation to compensate for capacity degradation.

2. Low-temperature performance optimization path:

Adopt low viscosity lithium bis(fluorosulfonyl)imide (LiFSI)

SEI film modification on anode surface (to reduce low-temperature impedance)

3. Structural risks of shaped batteries:

Avoid sharp angle design (radius of curvature >5mm) to prevent electrode stress concentration and fracture.

Flexible collector (e.g., nano-copper mesh) is needed for curved batteries.

VI. Cutting-edge Technology Enabling Customized Innovation

- Topology optimization design: automatic generation of high specific energy structure based on AI simulation platform (e.g. Ansys Granta MI)

- Digital twin testing: 80% validation completed in virtual environment (e.g. thermal runaway diffusion simulation)

- Solid-state battery customization: sulfide electrolyte to achieve intrinsic safety (mass production available in 2026)

Assertion: Successful Li-ion battery customization = precise demand x material innovation x extreme validation x process control, one of the four dimensions is missing.