Solid State Battery Packaging Processes 2025

I. Solid State Battery Packaging Process in 2025: Beyond the rigors of liquid batteries

Solid-state batteries (SSB) are leading the next generation of energy storage technology with their high energy density (>400 Wh/kg) and intrinsic safety (no flammable electrolyte). However, their unique solid-state electrolyte (sulfide/oxide/polymer) and interfacial characteristics place unprecedented special tasks on solid-state battery encapsulation process equipment:

Absolute airtightness requirements: isolate from water and oxygen to prevent electrolyte failure (e.g. sulfides form H₂S when exposed to water)

Strong corrosion resistance: resist electrolyte chemical attack on metal parts (e.g. sulfides corrode copper collectors)

Precision mechanical control: adapt to brittle solid electrolyte layers to avoid assembly damage

High pressure formation process: enhance interfacial ionic contact (60-80 tons of pressure vs. 3-10 tons in liquid batteries required)

Engineer’s insight: Encapsulation equipment is the “throat” of solid state battery from laboratory to mass production, and its performance directly determines the yield, life and safety of the battery cell.

II.Core Challenge 1: High Airtight Encapsulation – Constructing a Molecular Level Barrier

(1) Why do we need extreme hermeticity?

Electrolyte sensitivity:

Sulfide electrolyte meets >1 ppm H₂O → decomposition generates H₂S (toxic gas), ionic conductivity plummets >50%

Oxide electrolyte interface meets O₂ → formation of high impedance layer, internal resistance ↑30%

Performance and life guarantee: water-oxygen infiltration leads to 30%+ shortening of cycle life, accelerated decay of energy density.

(2) Equipment and process solutions

| Technical direction | Implementation path | key indicators |

|---|---|---|

| Advanced sealing materials | Metal-ceramic composite seals (such as Al₂O₃-filled fluorocarbon rubber), laser-sealed Kovar alloy | Helium leak rate ≤10⁻⁶ Pa·m³/s (MIL-STD-883) |

| High-precision welding | Vacuum electron beam welding (deep penetration, small heat-affected zone), fiber laser welding (positioning accuracy ±5μm) | Weld seam airtightness <10⁻⁵ Pa·m³/s |

| Environmental control | Class 100 clean room + dew point <-60°C ultra-dry environment (glove box/O₂&H₂O <0.1 ppm) | Water and oxygen content in the packaging environment ≤0.5 ppm |

III. Core Challenge II: Anti-electrolyte corrosion – the long-life code for equipment

(1) Corrosion mechanism and risk

Sulfide electrolyte: reacts with Cu collector to form Cu₂S, resulting in:

Contact resistance ↑200%

Stripping of active substances, capacity decay accelerated by 40%

High-voltage interface: oxidative corrosion of collector/binder at >4V on the anode side

(2) Corrosion-resistant equipment technology

| Protection strategy | engineering plan | Effect verification |

|---|---|---|

| Corrosion-resistant collector | Nickel-plated copper foil (Ni layer ≥1μm), titanium alloy current collector (sulfur corrosion resistant, cost ↑) | Resistance increase <10% after 500 cycles |

| Surface modification | ALD deposition of Al₂O₃ nanolayers (2-5 nm) on the inner walls of the device | Sulfur corrosion resistance life improved by 5 times |

| non-metallic components | PEEK engineering plastic (chemical resistance), ceramic coated bearings (replacing stainless steel) | Equipment maintenance cycle extended to 12 months+ |

IV. Core Challenge III: Precision Manufacturing and High-Pressure Formation – The “Gentle Hand” of Solid-State Battery Cells

(1) Brittle electrolyte layer treatment

The death of traditional winding: bending stress leads to cracks in sulfide electrolyte and disruption of ionic pathways

Upgrade of stacking process:

High-precision CCD visual positioning (accuracy ±10μm)

Piezo-ceramic micromotor platform (step resolution 0.1μm)

Flexible vacuum suction cups (contact pressure <5 N/cm²)

Output efficiency: 0.5-1 sec/chip (vs. 0.3 sec/chip for liquid batteries)

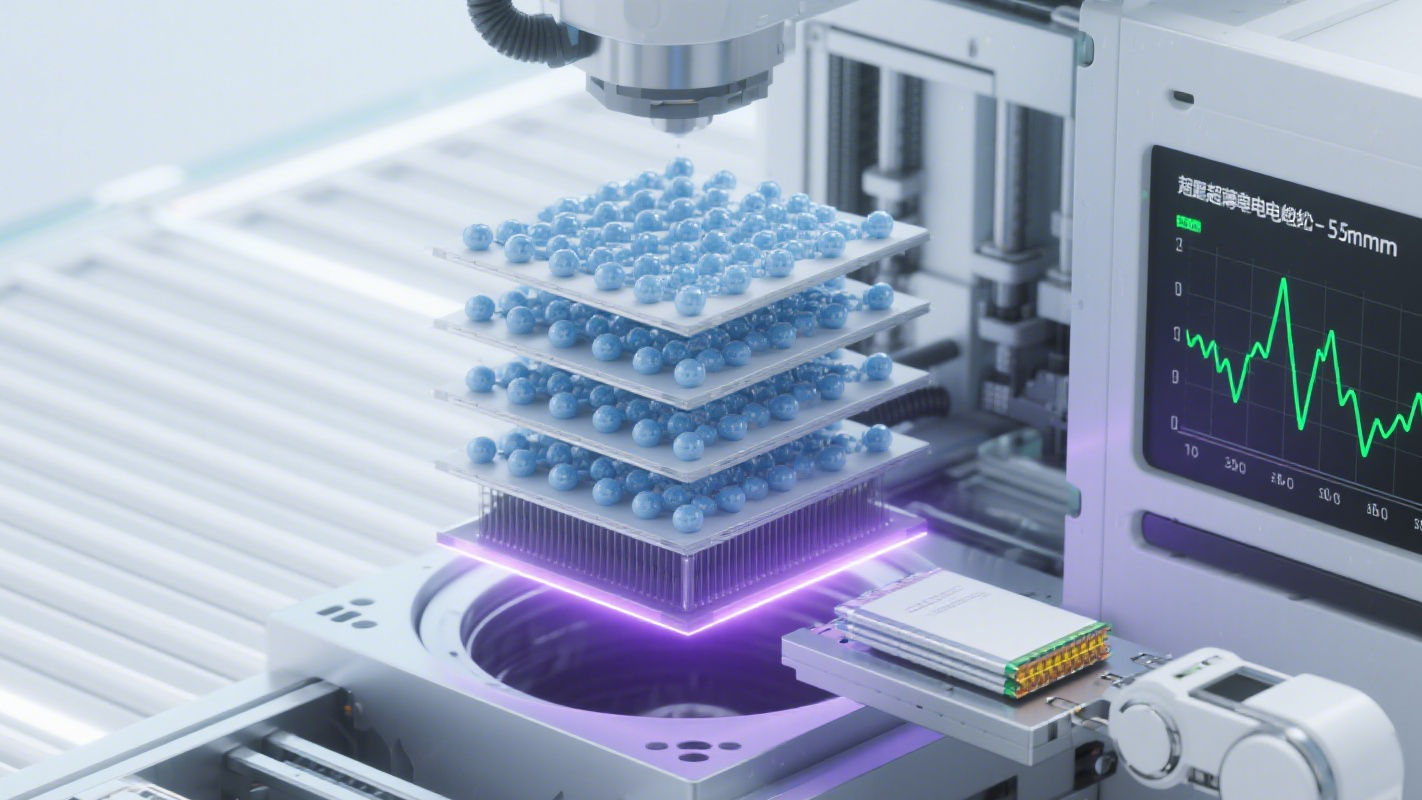

(2) High-voltage synthesis process equipment Chemical formation process equipment

Pressure requirement: 60-80 MPa (to promote close contact at the electrode/electrolyte interface)

Equipment innovations:

Multi-cylinder synchronized hydraulic system (pressure fluctuation <±1%)

Embedded pressure-impedance closed-loop feedback (real-time optimization of interfacial contact)

Effect: interfacial impedance reduced by 50%, first-time coulombic efficiency increased to >85%.

V. Technology mapping of cutting-edge equipment

| Processing steps | Solid-state battery dedicated equipment | Technological breakthroughs |

|---|---|---|

| Electrolyte film formation | Sulfide: Vacuum vapor deposition + hot pressing in one machine | Film thickness uniformity ±1μm, defect rate <0.1% |

| Oxide: Magnetron sputtering equipment | Deposition rate >50 nm/min, bonding force >20 MPa | |

| Polymer: precision coating + hot press | Thickness control ±2 μm, porosity 35±3% | |

| Battery cell assembly | Fully automatic high-speed laminating machine | Positioning accuracy ±15μm, UPH >200 |

| Chemical decomposition | High-voltage chemical storage cabinet | Pressure control ±0.5 MPa, temperature uniformity ±1°C |

VI.The future trend: intelligent and material innovation

1. Intelligent seal monitoring:

integrated MEMS gas sensor, real-time monitoring of H₂O/O₂ concentration inside the package (warning threshold of 1 ppm)

2. Self-healing sealing material:

microencapsulated repair agent (automatically released in case of cracks), airtightness maintenance >10 years

3. Atomic Layer Deposition (ALD) scale-up:

equipment capacity >1,000 tablets/hour, full-surface nano-corrosion protection coating for collector/diaphragm

4. Digital Twin Process Optimization:

Dynamically adjusts formation profiles based on pressure-temperature-impedance multi-parameter models.

Engineers assert that when encapsulation equipment realizes “zero-defect hermeticity” + “adaptive interfacial pressure control”, the manufacturing cost of solid-state batteries will be close to that of liquid-state batteries. battery. The beginning of the TWh-class mass production era.