2025 Lithium battery pack heat dissipation technology

Effective thermal management is the core element to ensure the safety and performance of lithium battery. As lithium battery technology engineers, we know that the design of the heat dissipation system directly affects the safety, performance and life of lithium battery packs. In this paper, we will analyze in-depth 2025 lithium battery pack thermal technology needs, and provide professional technical solutions.

I. Necessity of thermal management of lithium battery packs: critical conditions for thermal runaway of the battery

The heat generated by lithium batteries in the process of charging and discharging mainly comes from the heat of internal resistance and chemical reaction heat. If the heat cannot be emitted in time, it will lead to serious consequences:

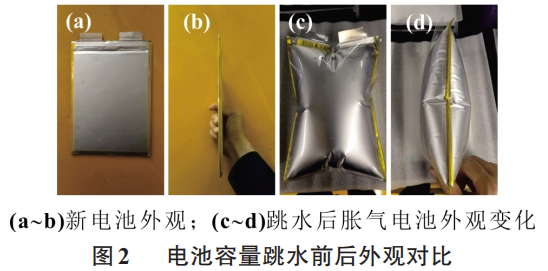

According to Arrhenius’ law, for every 10℃ rise in temperature, battery life is shortened by 30%-50%. When the temperature exceeds the critical value (about 150-200℃ for Li-ion ternary batteries and 250-300℃ for Li-FePO4 batteries), a chain reaction may be triggered, including melting of the diaphragm, decomposition of the electrolyte and expansion of the gas production, which ultimately leads to combustion or explosion.

The core role of the lithium battery pack cooling system is to maintain the battery pack temperature within the safe range of 20-40℃, and control the temperature difference between the cells at ≤5℃ to ensure the consistency and stability of the battery pack.

II.Lithium battery packs need key technical conditions of the heat dissipation system

High energy density battery cell (≥180Wh/kg)

The higher the energy density of the battery cell, the more energy is stored per unit volume, and the more concentrated the heat generated during charging and discharging. When the energy density exceeds 180Wh/kg, natural convection heat dissipation is often difficult to meet the demand, and a forced cooling system is required.

Typical cases of Li-ion battery pack heat dissipation system:

- Tesla 4680 battery (energy density of about 300Wh/kg) adopts liquid cooling plate + thermal conductive adhesive heat dissipation solution

- Nintendo Kirin battery optimizes the liquid cooling flow path through the inverted core and elastic sandwich design, which significantly reduces the temperature rise.

Li-ion battery pack high charge/discharge multiplier (≥1C)

Charge/discharge ratio directly affects the amount of heat production. According to Joule’s law, the heat generated by internal resistance is proportional to the square of current (I²R). When the continuous charge/discharge rate is ≥1.5C, a heat dissipation system must be equipped; when the peak rate is ≥3C, an efficient liquid cooling system is required.

Lithium battery pack thermal management application scenarios:

- Ultra-fast charging of electric vehicles (4C multiplier): liquid cooling system is required to control the temperature of the battery cell below 45°C

- Energy storage system FM (2C multiplier): frequent charging and discharging leads to rapid temperature rise, active heat dissipation is required

Lithium battery pack harsh ambient temperature conditions

When ambient temperatures are extreme, heat dissipation systems become a necessity:

High temperature environments (≥35°C):

- Tropical regions or high temperature environments in summer, battery pack surface temperatures may exceed 60°C

- Lack of natural ventilation in confined spaces (e.g., containerized energy storage) requires active heat dissipation

Low-temperature environments (≤ -10°C):

- Although heating is the main requirement, thermal management systems often integrate both cooling and heating modes

- Heat pump systems are able to meet the thermal management needs of both low and high temperature environments

Long life and high reliability of lithium battery packs

For applications requiring long cycle life (≥3000 cycles), temperature control is critical:

- Lithium iron phosphate batteries cycled at 45°C have a 40% shorter lifespan than at 25°C

- Lithium ternary batteries cycled at 50°C may have a lifespan of less than 2,000 cycles

Stabilizing the temperature of the battery packs at 25±3°C through a liquid cooling system extends the lifespan by more than 30% and significantly improves the return on investment.

Lithium battery pack high safety application areas

Specific applications have extremely high safety requirements and must be equipped with efficient heat dissipation systems:

- Electric vehicles: need to meet GB/T 31467.3 thermal dispersion occupant protection test standard

- Aviation batteries: need to pass DO-311A avionics thermal safety standard

- Medical equipment: zero thermal runaway risk to ensure absolute safety

III.Lithium battery pack heat dissipation system type and technology selection

According to the application requirements, different heat dissipation solutions can be selected:

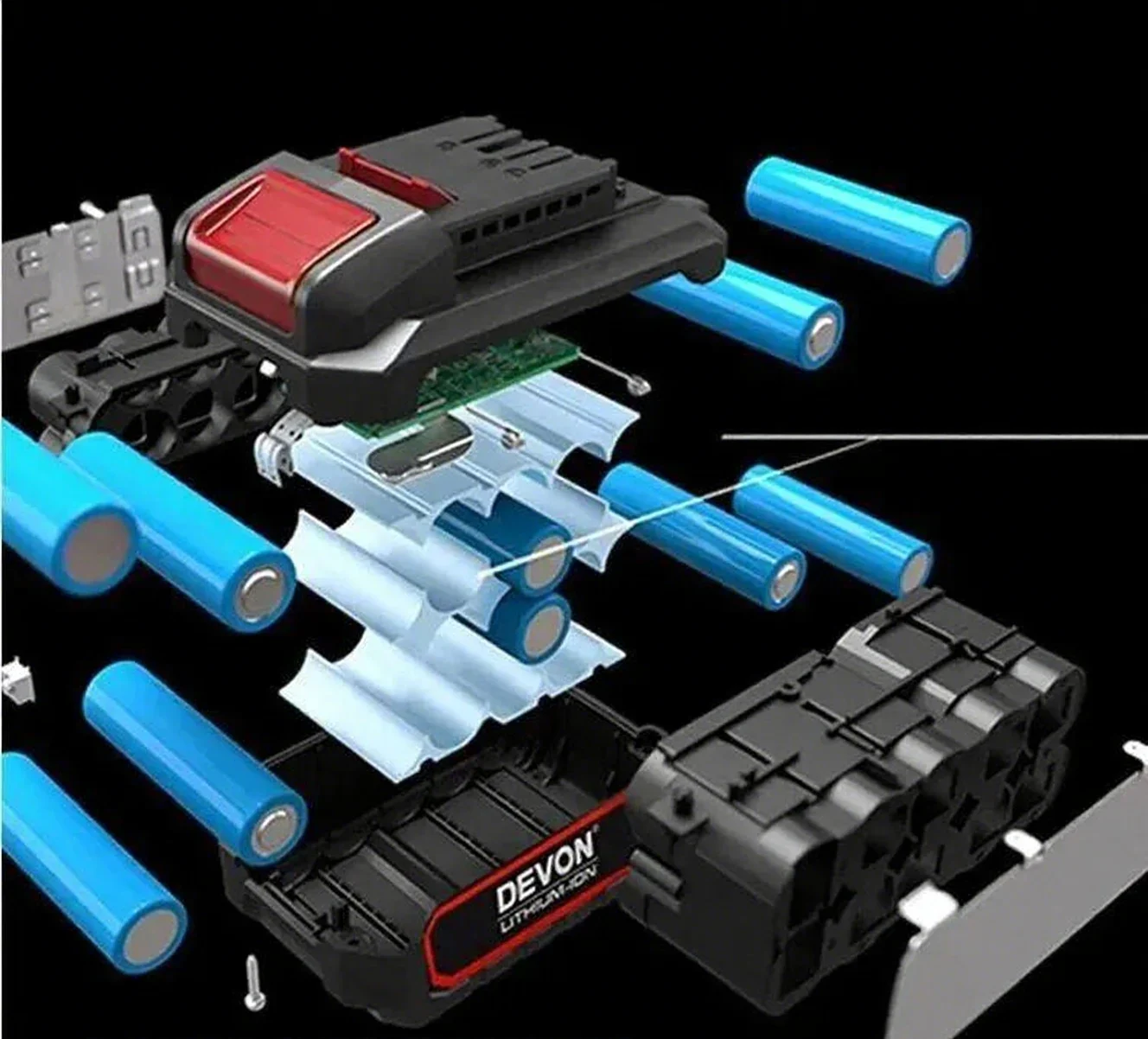

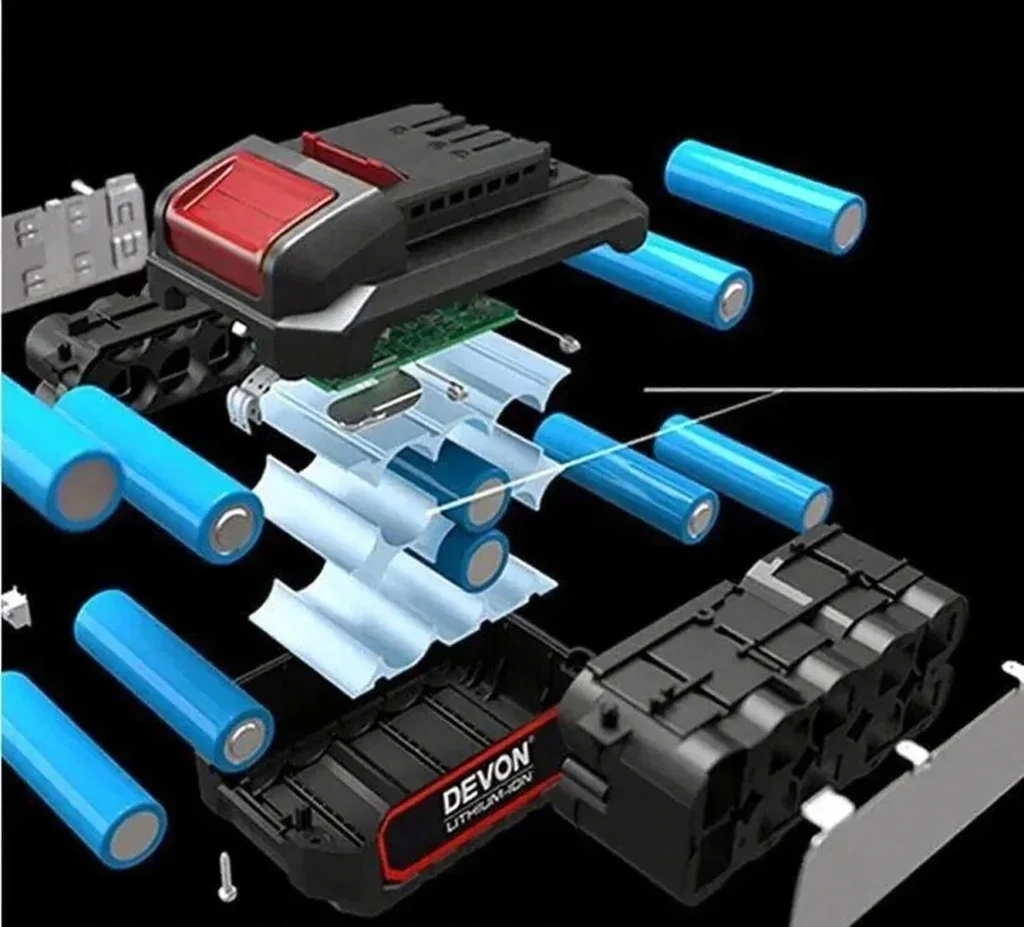

Lithium battery pack air cooling system9

Suitable for low to medium power density applications with lower cost but limited heat dissipation capability. Typically used for:

- Small energy storage systems

- Low-power power tools

- Applications with energy density ≤ 150 Wh/kg

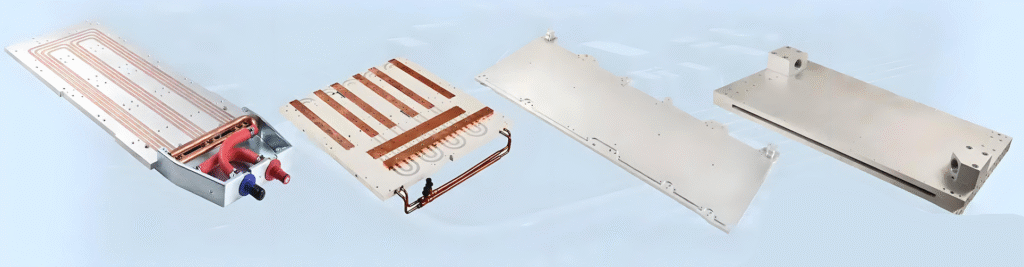

Liquid Cooling System for Lithium Battery Packs

Highly efficient thermal solution for high power and high energy density applications:

- Electric vehicle power batteries

- High power industrial equipment

- Applications with energy density ≥180Wh/kg

Phase Change Materials (PCM) for Lithium Battery Packs

Utilizes material phase change process to absorb heat, suitable for transient high rate applications:

- Drone batteries (e.g. custom drone battery packs)

- High rate discharge tools

- Space-constrained compact devices

IV. lithium battery pack heat dissipation system engineering practice cases

Tesla Model 3 liquid cooling system

Adopting 21700 Li-ion ternary battery (energy density 260Wh/kg), the liquid-cooled plate + heat-conducting gel design controls the temperature of the battery core in the range of -10℃ to 55℃, supporting 4C ultra-fast charging and guaranteeing capacity retention rate ≥80% after 1200 cycles.

Industrial energy storage system thermal management

Using 280Ah Li-FePO4 battery (energy density 160Wh/kg), equipped with air-cooled + intelligent speed control fan system, which automatically adjusts the wind speed according to the temperature rise, and realizes 8,000 cycles of life under 40℃ environment to meet the demand of 15 years of use.

Drone Battery Thermal Solution

Aiming at the special needs of custom drone battery pack, phase change material (paraffin) is used to fill the gap of the battery cell, effectively absorbing the transient heat generated by charging and discharging, and supporting 30C high rate discharge while controlling the surface temperature at ≤60℃.

V.Lithium battery pack heat dissipation system design principles

Preventive design

Predict the temperature rise distribution in advance through thermal simulation analysis (e.g. Fluent, Star-CCM+) to optimize the heat dissipation structure design and avoid the cost of later modification.

Dynamic Intelligent Regulation

Combine with BMS system to monitor the temperature data in real time, dynamically adjust the coolant flow or fan speed to realize accurate temperature control and reduce energy consumption.

Balance between lightweight and reliability

Under the premise of meeting the heat dissipation requirements, lightweight materials such as aluminum liquid-cooling panels are used, and system reliability is ensured through redundant design, especially in application scenarios with extremely high safety requirements.

Optimization of cost-effectiveness

Choose the appropriate cooling solution according to the specific application requirements, avoid over-design, and strike the best balance between performance, reliability and cost.

VI. Lithium battery pack heat dissipation system decision-making criteria and implementation recommendations

The final judgment criteria of whether the lithium battery pack needs to increase the heat dissipation system:

- The temperature rise rate of the battery pack under any working condition is more than 5℃/min

- The peak temperature is close to the safety critical temperature of the battery cell

- The temperature difference between the battery cells is more than 5℃, which affects the consistency of the battery pack

- The temperature of the application environment is continuously out of the ideal range of 15-35℃.

Lithium battery pack heat dissipation system implementation recommendations:

- Conduct detailed thermal simulation analysis to predict the temperature distribution under the worst working conditions

- Select appropriate heat dissipation technology solutions according to the application scenario

- Design redundant safety mechanisms to ensure that a single point of failure will not lead to thermal runaway

- Establish a comprehensive temperature monitoring and protection system

- Conduct sufficient testing and verification to ensure the reliability of the heat dissipation system under various working conditions

VII. Li-ion battery pack heat dissipation system for special applications: drone battery packs

For special applications such as custom drone battery packs, thermal design requires additional considerations:

Weight constraints: the weight of the cooling system directly affects flight performance

Space constraints: compact designs require innovative cooling solutions

Varying environments: the need to adapt to extreme conditions such as low temperatures at high altitude and intense sunlight

Transient high power: to meet the need for high rate discharges during takeoffs and maneuvers

Phase-change materials in combination with smart air-cooling are often the best choice to control weight and manage transient high thermal loads effectively.