Lithium Battery 4680 Cell Teardown Report

Comprehensive Analysis of the Structural Design, Material System, and Manufacturing Process of the Lithium Battery 4680 Large Cylindrical Cell

As lithium battery technology engineers, we recognize that the lithium battery 4680 cell represents the pinnacle of current cylindrical battery technology. Based on actual teardown analysis, this paper provides an in-depth examination of the technical characteristics, process innovations, and future development trends of the lithium battery 4680 cell, offering professional reference for industry peers.

I. Overview of the 4680 Lithium Battery Cell: Technical Characteristics and Market Strategy

The 4680 lithium battery cell (46mm diameter, 80mm height) is a next-generation cylindrical battery specification introduced by Tesla at its 2020 Battery Day. Compared to the previous 2170 battery, the 4680 achieves significant improvements in energy density, power output, and cost efficiency: energy capacity increases fivefold, power output rises sixfold, and costs decrease by 14%.

This large cylindrical battery incorporates innovative technologies such as full-tab design and dry electrode processes, optimizing thermal management, production efficiency, and charging speed. Major battery manufacturers including Panasonic, LG, Samsung, EVE Energy, CATL, and BAK have all initiated R&D and production of the 4680 cell.

II. Structural Design Differences in Lithium-Ion 4680 Cells: Tesla vs. Domestic Solutions

Overall Design Differences

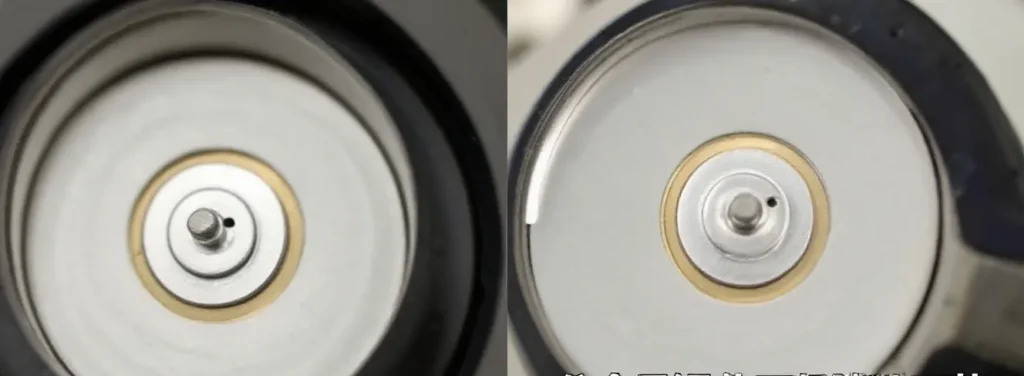

Significant design discrepancies exist between Tesla and domestic lithium-ion 4680 cells. Tesla’s rapid technological iteration results in noticeable aesthetic variations across different generations of 4680 cells. The second-generation 4680 cell exhibits substantial changes in its negative electrode cover plate, clearly revealing three weld seams.

Cylindrical cells require far more welds than prismatic cells. Each cell necessitates at least two welds for both positive and negative electrodes. Mainstream prismatic power cells typically have capacities of 100–200Ah, far exceeding the 25–30Ah capacity of 4680 cells. Increased adoption of 4680 cells will drive growth in laser equipment.

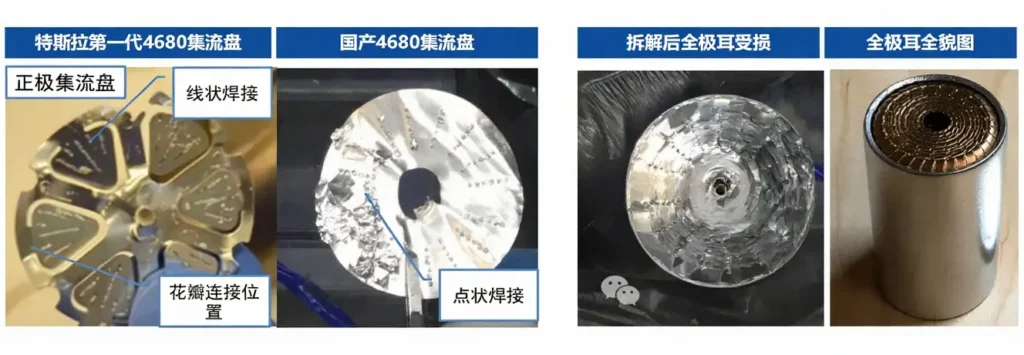

Current Collector Design Differences

The positive current collector design exhibits distinct variations:

- First-generation Tesla 4680 lithium battery positive current collector: Features 6 petals, each with 3 long and 2 short welds totaling 5 welds per petal

- Domestic 4680 lithium battery current collector: Utilizes spot welding without petal-shaped structures

- Welding the current collector to the full tab presents a significant manufacturing challenge

Insulation Design Comparison

Insulation design also reflects differing philosophies:

- First-generation Tesla 4680 lithium battery positive electrode insulation sheet covers the entire cell cross-section. All current from the full tab ultimately converges at the positive electrode post, concentrating heat at this location and potentially impacting fast-charging performance.

- Domestic 4680 lithium batteries also feature insulation sheets, but their thickness is significantly lower than Tesla’s design.

III. Full Tab Technology for 4680 Lithium Battery Cells: Process Challenges and Innovative Solutions

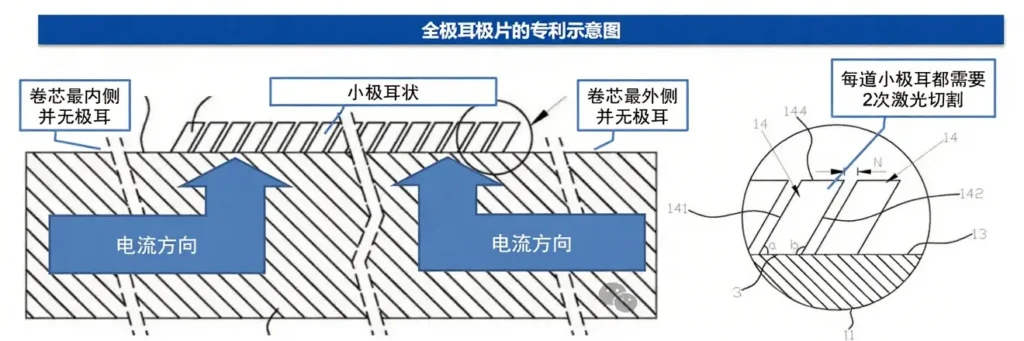

Key Features of the Full Tab Design in Lithium Battery 4680 Cells

The full tab design represents a core innovation in lithium battery 4680 cells. While traditional batteries feature only two tabs connecting the positive and negative electrodes, the 4680 battery achieves a full tab configuration (where tabs are directly cut from the positive/negative electrodes). This significantly increases the current path, reduces tab spacing, and consequently lowers internal resistance while enhancing rate performance.

Teardown analysis reveals clearly visible, densely arranged tab edges on the current collector material. Both the positive aluminum foil and negative copper foil edges exhibit a dense micro-tab structure, a design that substantially increases manufacturing process control complexity.

Lithium Battery 4680 Cell Tab Process Challenges

Analysis of full-tab electrode sheets reveals multiple technical hurdles:

- The core of the rolled cell features a hollow structure, resulting in no tabs on the innermost layer.

- Welding the outermost micro-tabs to the current collector plate becomes more challenging, and the outermost layer also lacks tabs.

- Current in the innermost and outermost layers first flows along the electrode sheet’s length before moving across its width.

- Each small tab requires two laser cuts, significantly increasing processing complexity

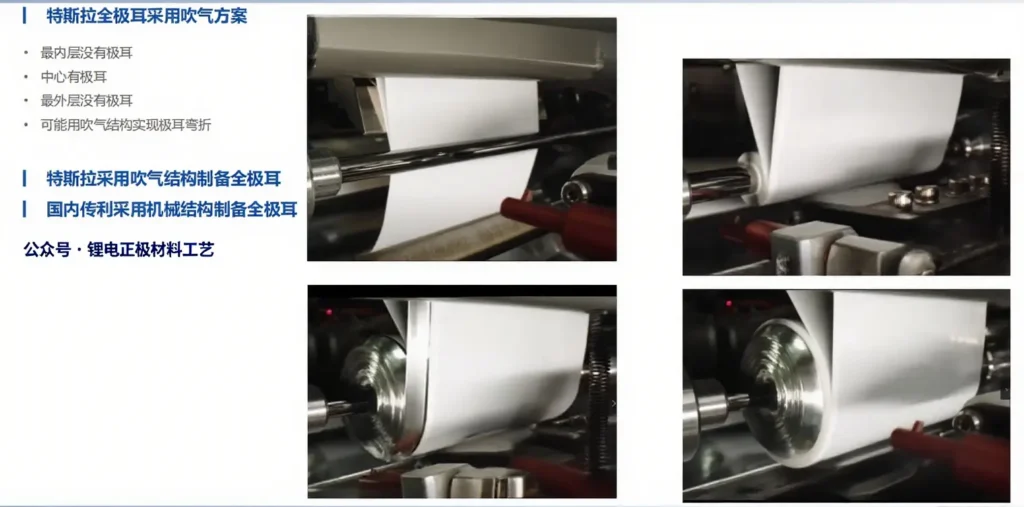

Innovations in Lithium Battery 4680 Cell Tab Flattening Process

Full-tab flattening is a critical process, with significant differences between domestic and Tesla solutions:

- Flattening Process: Flattening the cross-section of the rolled core before welding to the electrode plate. This is achieved either by direct flattening via ultrasonic vibration or by direct friction against the battery tab surface using a rotating flattening wheel.

- Process Challenges: Excessive flattening speed causes tab curling; insufficient speed reduces production efficiency; metal shavings may cause internal short circuits; active material shedding; tab wrinkling, etc.

Innovative solutions include:

- – Applying a flattening sleeve over the full tab. The flattening head rotates while approaching the sleeve to prevent crushing the full tab section.

- – Ultrasonic flattening pre-treats the cell end face before mechanical flattening.

- – Flattening-free technology: Applying insulating material to the blank edge area after coating, matching the height of the active material, ensuring the current collector forms a complete flat surface after winding.

Tesla employs a unique air-blowing solution for full tab preparation: featuring a central tab with no outer layer, potentially utilizing an air-blowing structure to achieve tab bending. Domestic manufacturers predominantly use mechanical structures for full tab preparation.

IV. Production Process Flow for Lithium Battery 4860 Cells: Enhanced Precision and Complexity

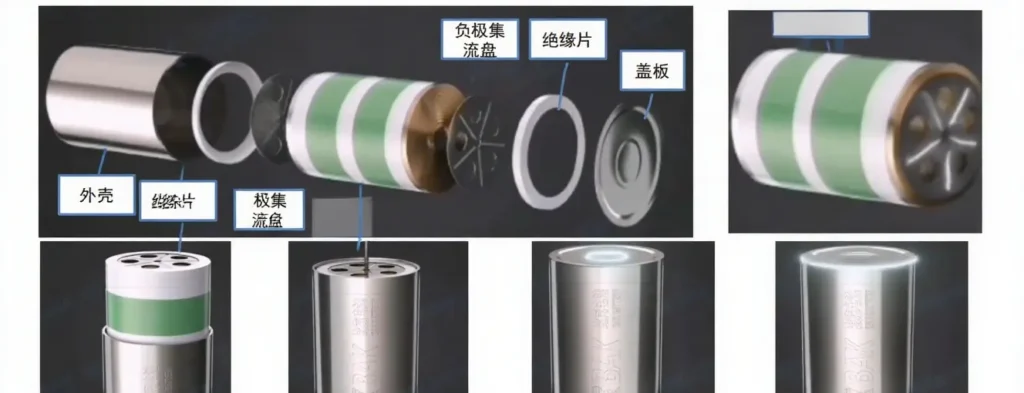

The cylindrical battery production process can be broadly divided into: casing preparation, positive electrode insulator installation, positive current collector installation, winding, negative electrode current collector installation, negative electrode insulator installation, and lid sealing. Processes such as casing insertion after current collector welding, positive electrode welding, negative electrode welding, and sealing demand extremely high precision.

The 4680 battery production process presents significantly heightened laser welding challenges. Unlike traditional cylindrical batteries with only two tab spot welds, the larger 4680 cylindrical battery features multiple tabs. Both positive and negative electrodes are fully welded to the current collector, which itself has numerous fine filament welds. This results in a substantial increase in weld points (the 4680 has five times more weld points than the 21700).

Laser welding confronts numerous technical challenges: continuous welding risks incomplete or excessive penetration; ensuring battery internal uniformity, density, and current collector integrity is essential; metal residue and debris pose issues; thermal buildup during welding occurs; and full tab configurations remain uncontrollable.

V. Material System Analysis: Cathode, Anode, and Case Characteristics

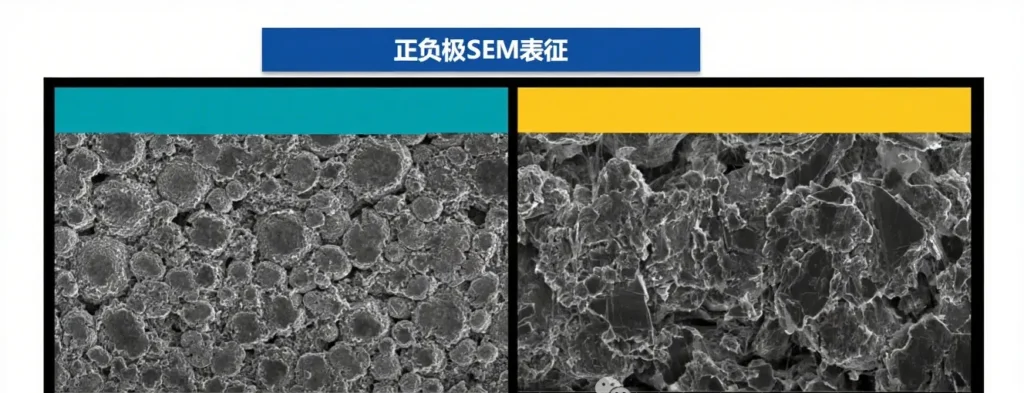

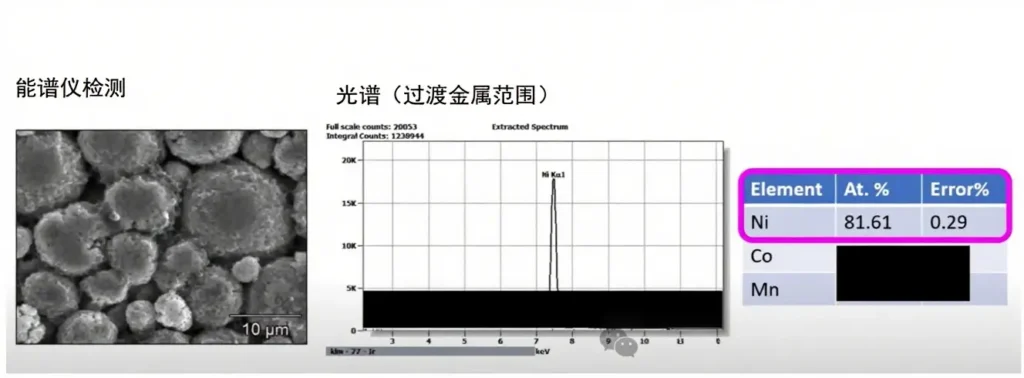

Cathode Material Characteristics

The first-generation Tesla 4680 cathode employs high-nickel material with approximately 80% nickel content, though it is not NCMA material or contains extremely low aluminum levels. The market share of high-nickel materials continues to decline, and the 4680 format helps stimulate the development of high-nickel materials.

Anode Technology Characteristics

Anode material analysis reveals key features:

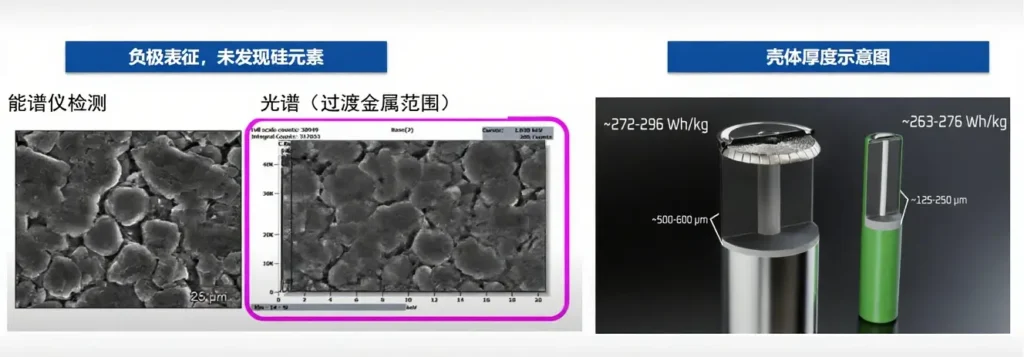

- The first-generation Tesla 4680 anode confirmed the use of dry electrode technology, while the cathode did not employ this method.

- Spectrometer analysis confirmed the Tesla 4680 anode consists solely of carbon, without silicon anode adoption.

- In contrast, Panasonic’s 21700 cells utilize 5–10% silicon.

The primary challenge with silicon-carbon materials is expansion. Compared to prismatic cells, cylindrical cells exhibit greater tolerance to expansion. This provides crucial insights for future customization of lithium-ion 4680 batteries.

Case Structure Design

The 4680 case thickness ranges from 500 to 600μm, whereas the 2170 case thickness is only 125 to 250μm. The 4680’s side casing thickness is 0.635 mm, with an estimated mass of 58 g. Using a 0.2 mm casing would reduce mass to just 18 g. The total cell weight is 355 g, indicating an 11.2% increase due to the thicker casing.

VI. Performance Parameters and Energy Density

The specific parameters of the first-generation Tesla 4680 cell are as follows:

- Electrode Dimensions: 330 × 7.2 cm

- Capacity: 26.136 Ah

- Energy: 96–99 Wh

- Weight: 355 g

- Energy Density: 272–296 Wh/kg

These parameters demonstrate a significant improvement in energy density compared to previous generations, laying the foundation for extended driving ranges in electric vehicles.

VII. Technical Challenges and Innovative Solutions

Application of Dry Electrode Process in

Tesla employs dry electrode technology in its 4680 batteries, which differs significantly from traditional wet coating methods. Dry coating involves mixing positive and negative electrode particles with PTFE binder. A jet mill applies high shear force to the mixture, mechanically stretching it into a fibrous mesh layer. This layer is then rolled onto aluminum or copper foil to form electrode sheets.

Compared to wet coating, dry coating offers distinct advantages: it eliminates the need for solvents, skips processes like slurry mixing, drying, and hazardous solvent recovery, and reduces material, time, facility, and labor costs. Dry-coated electrodes are thicker, achieve higher energy density, and offer better compatibility with the 4680 battery.

Innovation in Electrode Sheet Cutting Technology

The 4680 battery employs an integrated electrode sheet and tab cutting process. Traditional cutting methods use step-motion die-cutting, which is inefficient, costly, and requires frequent equipment size changes. The 4680 adopts a non-traditional approach, forming tabs continuously on one side of the foil during sheet cutting.

By cutting the electrode edge into multiple parallelogram-shaped tab units instead of rectangular ones, this approach eliminates electrode curling during flattening. It also prevents scratching the inner walls of the battery casing during assembly, reduces metal shavings, avoids short circuits, and decreases roller pressure during flattening. This prevents active material shedding and improves yield rates.

VIII. Latest Technological Advances and Future Trends

According to the latest data, Tesla continues to make progress in its 4680 battery technology. In the second quarter of 2024, Tesla produced over 50% more 4680 batteries than in the first quarter. By September 2024, Tesla had manufactured more than 100 million 4680 cells.

Recent innovations include:

- Introduction of LFP chemistry: Utilizing more abundant and cost-effective materials (iron, lithium, and phosphate) suitable for affordable electric vehicles

- Performance enhancements: Latest 4680 cells achieve charging speeds up to 500kW, representing significant improvements

- Structural innovation: Integrated structural battery technology enables cells to serve as part of the vehicle’s frame, reducing weight and enhancing stability

Tesla also plans to introduce four new 4680 battery variants by 2026, including the “Workhorse” battery for models like the Cybertruck, Semi, and Robo Van.

IX. Industrial Impact and Supply Chain Development

The industrialization of 4680 batteries is driving growth across the entire lithium battery supply chain. From an investment perspective, the following areas warrant attention:

- 4680 Power Battery Manufacturing: CATL, EVE Energy, and others actively expanding production

- High-Nickel Ternary Cathode Materials: Suppliers like Rongbai Technology, Xiamen Tungsten New Energy, Changyuan Lithium Technology, Dangsheng Technology, and Zhenhua Technology stand to benefit

- Anode Materials: Companies such as Beryl Technology and Xinde New Materials face new opportunities

- Separators: Companies like Star Energy Materials and ENJIE provide critical materials

- Electrolytes: Suppliers including New Energy Chemical and Tinci Materials adapt to new requirements

- Structural Components: Firms like Keda Li, Dongshan Precision, and Dongfang Electric Heating develop specialized assemblies

- Conductive Additives: Firms like TIANNAI Technology and Dowell Technology supply key additives

- Laser Equipment: Equipment manufacturers like LY Laser and Haimuxing secure new orders

X. Technical Considerations for Customizing 4680 Batteries

For users with specialized requirements, customizing lithium-ion 4680 batteries involves a multifaceted approach. From a technical perspective, key considerations include:

Material System Selection:

Cathode Material: High-nickel ternary offers high energy density, while lithium iron phosphate (LFP) provides superior safety and cycle life

Anode Material: Graphite anodes are mature and stable, whereas silicon-based anodes deliver higher capacity but face expansion challenges

Structural Design Adjustments:

Case Thickness: Balancing safety requirements with weight considerations

Insulation Design: Selecting appropriate insulation solutions and thicknesses based on application environments

Current collector design: Optimizing collector structure and welding methods based on current requirements

Process selection:

Choosing between dry electrode and wet electrode processes

Determining full tab forming methods (air-blowing vs. mechanical)

Optimizing and selecting welding techniques

Customizing 4680 batteries requires thorough consideration of specific end-use requirements, balancing factors such as energy density, power density, safety, cycle life, and cost.