Basic Parameters of Lithium Batteries in 2025

Capacity, voltage, rate capability, and internal resistance collectively form the foundation of lithium battery performance. Understanding the fundamental parameters of lithium batteries in 2025 means grasping the key to evaluating battery performance. As lithium battery engineers, we engage with these parameters daily: capacity determines how much energy a battery can store, voltage influences system architecture design, rate capability directly relates to charging and discharging speed, while internal resistance serves as a critical metric for measuring energy conversion efficiency.

These parameters are not only interrelated but collectively determine lithium battery performance in end-use scenarios—whether for drones demanding high energy density or energy storage systems requiring extended cycle life.

Capacity: The Fundamental Unit of Energy Storage

Capacity is the fundamental parameter measuring a battery’s ability to store electrical energy. It is defined as the amount of electricity a battery can release under specific conditions, calculated as: Capacity = Current × Time. Units are typically ampere-hours (Ah) or milliampere-hours (mAh).

A battery with a nominal capacity of 52Ah indicates that it can theoretically sustain operation for 1 hour when discharged at a current of 52A. However, it is important to note that battery capacity is influenced by multiple factors, including electrode materials, manufacturing processes, and operating environments. Even batteries of the same model, such as 18650 cells, can exhibit capacities ranging from 1000mAh to 3500mAh.

More critically, capacity does not directly equate to energy storage. A battery’s total stored energy is determined by both capacity and voltage: Energy (Wh) = Capacity (Ah) × Voltage (V).

For example: A 52Ah lithium iron phosphate battery (nominal voltage 3.2V) stores 166.4Wh of energy, while a 50Ah ternary battery (nominal voltage 3.7V) stores 185Wh. This is why comparing capacity alone does not accurately assess a battery’s actual energy storage capability.

Voltage: The Energy Level of Battery Systems

Voltage represents the potential difference between a battery’s positive and negative electrodes, primarily determined by the electrochemical properties of the electrode materials. Once the electrode material system is established, the battery’s voltage range is largely fixed.

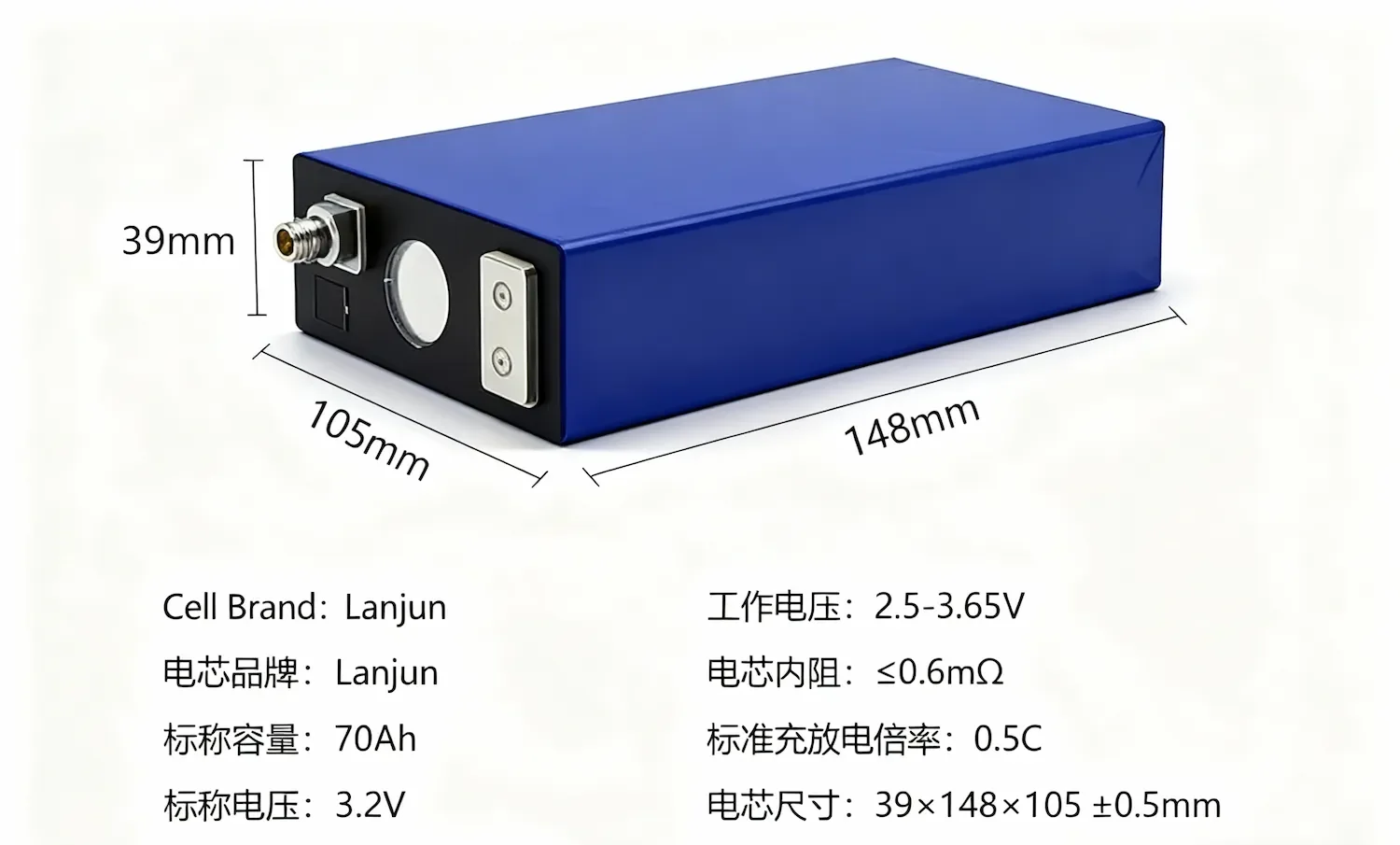

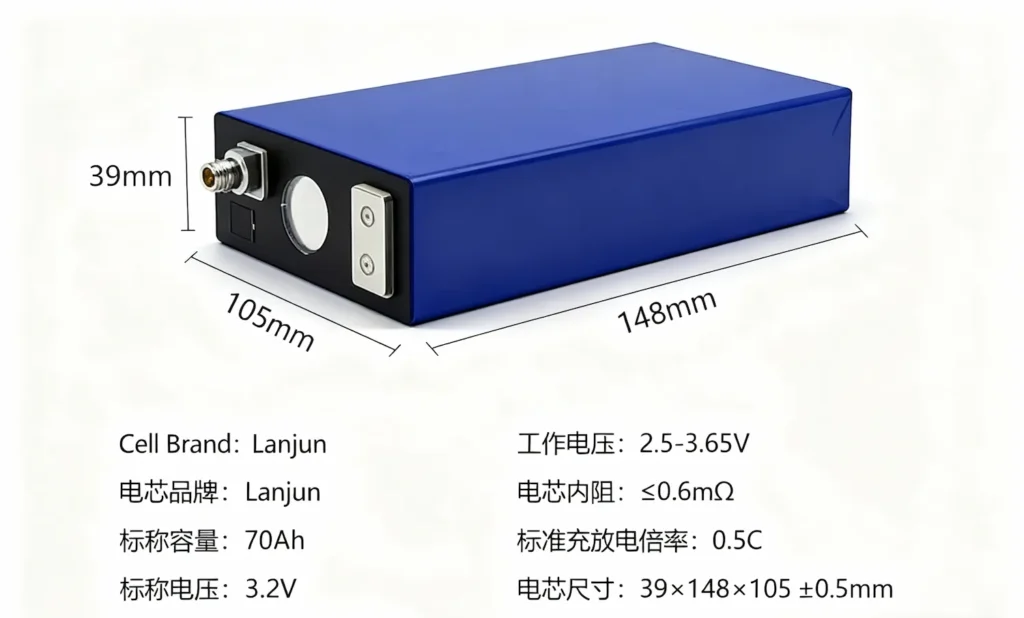

Voltage characteristics of mainstream lithium battery systems on the market:

- Lithium Iron Phosphate (LFP) Battery: Nominal voltage 3.2V, typical operating range 2.5-3.75V

- Ternary Lithium Battery: Nominal voltage 3.7V, typical operating range 2.8-4.2V

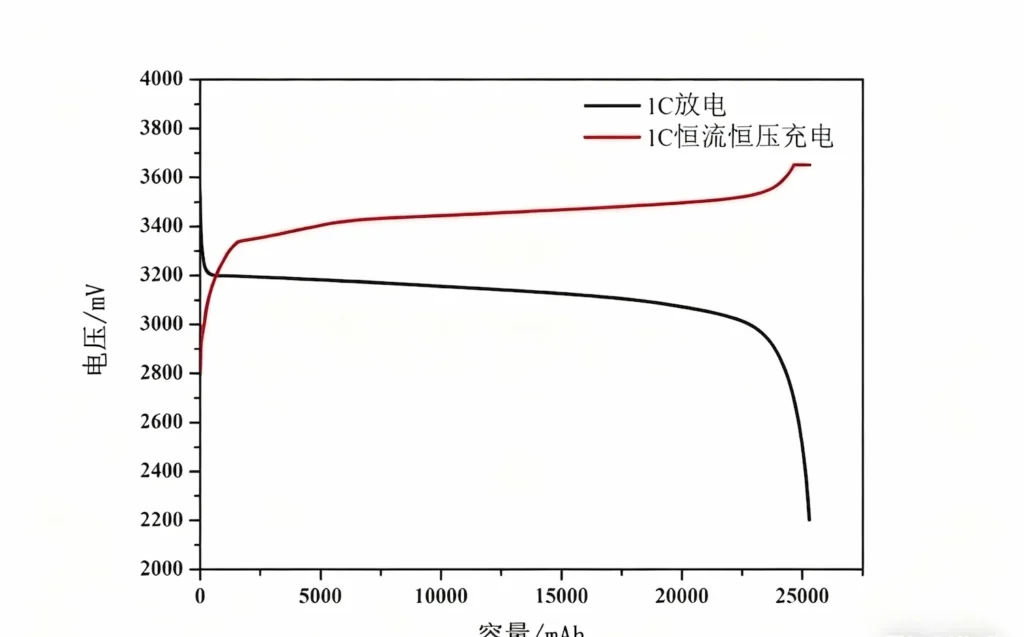

During lithium battery charging and discharging, the voltage curve shape reflects the battery’s internal state and material properties. Lithium iron phosphate batteries exhibit a flat discharge plateau, while ternary batteries show a continuous voltage decline. Strictly controlling charge and discharge voltages within specified limits is critical, as overvoltage charging or undervoltage discharging may cause performance degradation or safety hazards.

C-rate: The Key Indicator of Charge/Discharge Speed

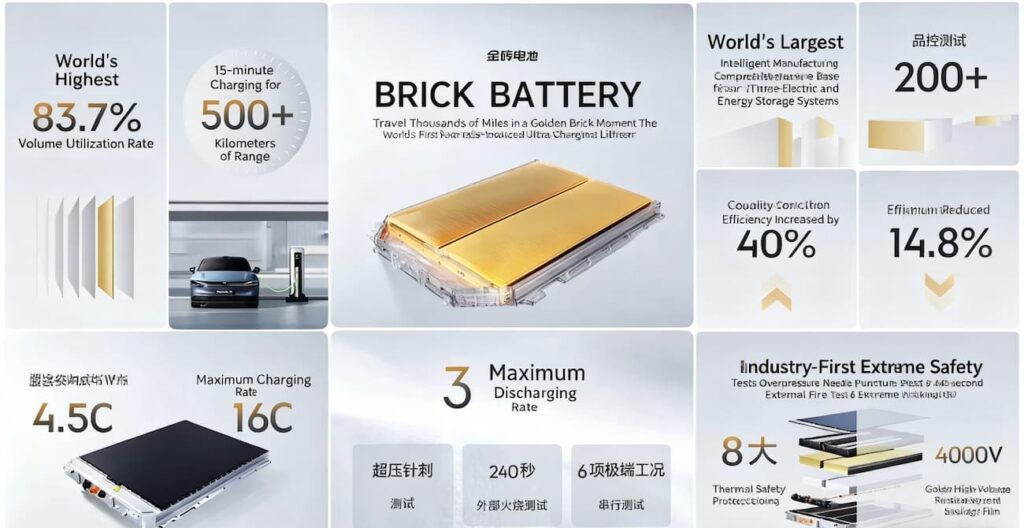

C-rate serves as the core parameter for measuring battery charge/discharge speed, defined as the ratio of charge/discharge current to the battery’s rated capacity: C = Current (A) / Capacity (Ah). C-rate inversely correlates with time—1C corresponds to a full charge in 1 hour, 2C takes 0.5 hours, and 4C requires only 15 minutes.

Based on their rate characteristics, lithium batteries are typically categorized into three classes:

- Low Rate (<1C): Primarily used in applications like energy storage where charging/discharging speed is less critical

- Medium Rate (1-10C): Meets the needs of most consumer electronics and electric vehicles

- High Rate (>10C): Suitable for devices requiring instantaneous high-power output, such as drones and power tools

It is crucial to emphasize: High-rate charging and discharging negatively impacts battery lifespan. While technological advancements now enable batteries supporting 6C or higher rates (e.g., Huawei’s Giant Whale battery supports 6C fast charging), sustained high-rate operation still accelerates battery degradation.

Internal Resistance: The Core Measure of Energy Conversion Efficiency

Internal resistance is a key metric for evaluating battery performance, representing the resistance encountered by current flowing through the battery’s interior. It is typically measured in milliohms (mΩ). A lower internal resistance value indicates higher energy conversion efficiency, reduced heat generation, and superior power characteristics.

Key factors influencing internal resistance include:

- Electrode material properties

- Electrolyte ionic conductivity

- Separator performance

- Manufacturing process (lamination typically yields lower internal resistance than winding)

Power batteries typically require internal resistance below several milliohms to ensure efficient energy conversion and minimal thermal loss. Internal resistance also increases with battery aging, making it a crucial parameter for assessing State of Health (SOH).

Interactions and Trade-offs Among Parameters

These core parameters do not exist in isolation but are interconnected and mutually constrained. For example:

- Increasing battery capacity often leads to higher internal resistance, affecting rate performance.

- Reducing internal resistance may require optimizing material systems, but this can compromise voltage stability.

- High-rate designs typically require sacrificing some capacity.

In practical applications, we must identify the optimal balance among these parameters based on specific requirements. Drone batteries may prioritize high-rate capability and low internal resistance, while energy storage batteries focus more on capacity and cycle life.

Advancements in lithium battery technology are largely reflected in the continuous optimization of these parameters: higher capacity, more stable voltage platforms, higher rate performance, and lower internal resistance. As engineers, we strive daily for incremental improvements in these parameters—whether reducing internal resistance by a few milliohms or boosting rate performance by a fraction of a C-rate.

These seemingly minor gains, when accumulated, form the fundamental driving force propelling the entire industry forward.