Core Technical Parameters of Drone Batteries

Mastering battery parameters is key to enhancing drone performance. Proper battery selection can extend flight time by over 30%.

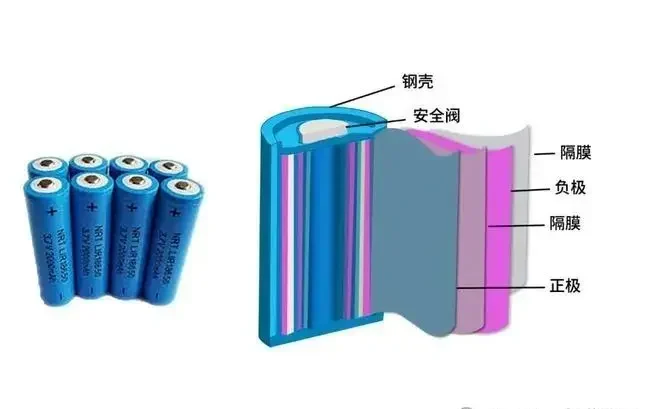

As a lithium battery engineer, I understand that drone batteries serve as the aircraft’s “heart.”Core performance parameters of drone batteries directly determine flight duration, payload capacity, and safety. Currently, mainstream drones predominantly utilize lithium polymer batteries (LiPo) and high-voltage lithium batteries (LiHV), each offering distinct advantages in energy density and discharge performance.

LiPo batteries, renowned for their excellent cost-performance ratio, remain the preferred choice for consumer-grade drones. Meanwhile, LiHV batteries leverage their higher voltage platforms to deliver enhanced power for professional aerial photography and racing drones. Understanding battery parameters not only aids in selecting suitable products but also effectively extends battery lifespan.

I. Core Voltage Parameters of Drone Batteries: The Foundation of Battery Operation

Nominal Voltage and Operating Range of Drone Lithium Polymer Batteries

The nominal voltage of drone lithium polymer batteries is 3.7V, serving as the baseline for calculating total pack voltage. For example, a 6S battery pack voltage is 6 × 3.7V = 22.2V.

Charge cut-off voltage is typically 4.2V (4.35V for LiHV batteries). Continued charging beyond this voltage may damage battery performance. Discharge cut-off voltage generally ranges between 2.5V and 3.0V, preventing irreversible damage from over-discharge.

Importance of Storage Voltage for Drones

During long-term storage, drone batteries should be maintained at a storage voltage of 3.8V–3.9V. Although lithium batteries have a low self-discharge rate, voltage gradually decreases over time. Maintaining an appropriate storage voltage maximizes battery lifespan.

II. Drone Battery Configuration: Series and Parallel Connections Determine Performance

Relationship Between Series Cells (S Count) and Voltage

The number of series cells (S count) directly determines the battery pack voltage. Each additional series cell increases the voltage by 3.7V. Industrial-grade drones commonly use a 12S configuration (44.4V), while consumer-grade drones typically employ 3S to 6S configurations.

High-voltage systems offer advantages in reducing transmission losses, requiring lower current at equivalent power levels, and generating less heat in cables and connectors.

Parallel (P Count) and Capacity Relationship

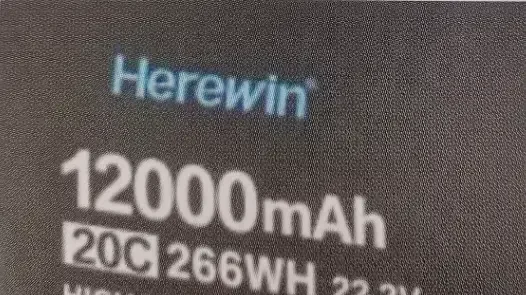

The number of cells connected in parallel (P count) determines the battery pack’s capacity. A 2P configuration doubles the capacity of a single cell while maintaining the same voltage. High-capacity drone batteries typically employ multiple parallel designs; for example, a 12000mAh 6S2P battery consists of 12 cells.

III. Drone Battery Capacity and Charge Level: Determinants of Flight Duration

Units and Practical Significance of Drone Battery Capacity

Drone battery capacity is measured in mAh or Ah, representing the battery’s ability to sustain discharge at a specific current. A 10,000 mAh battery can discharge at 10A for one hour or at 20A for half an hour.

Note that actual capacity decreases during high-rate discharges due to limitations imposed by internal resistance and chemical reaction rates.

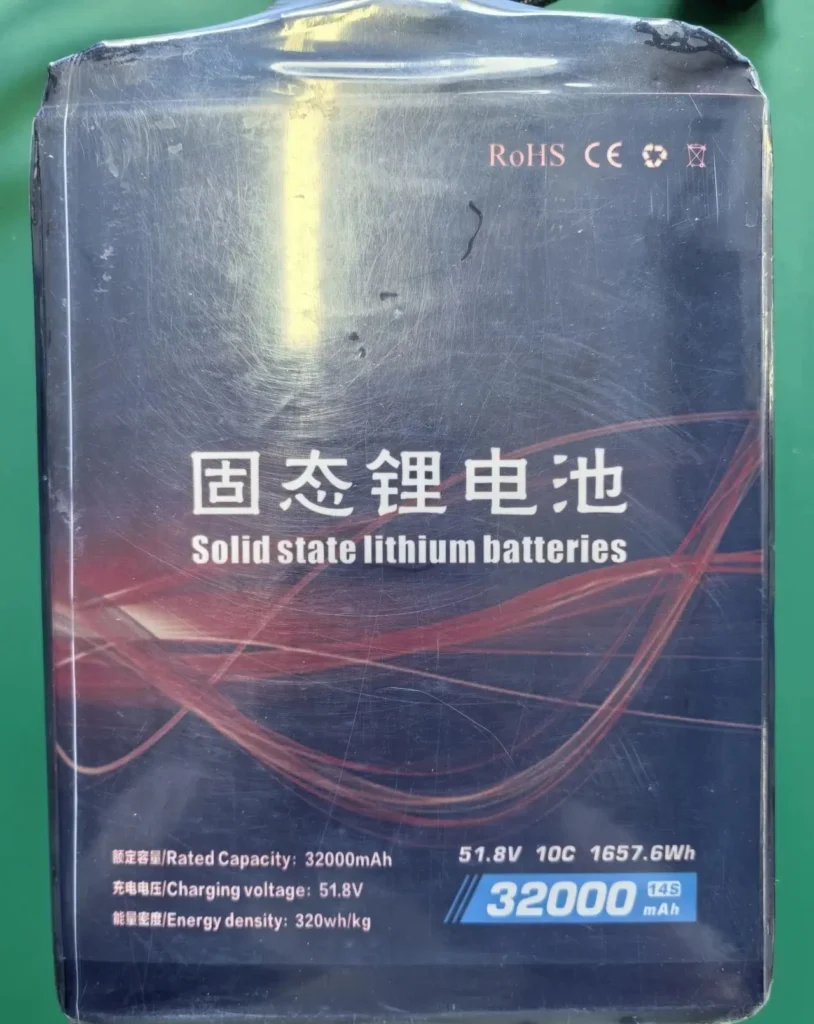

Drone Battery Energy Calculation and Energy Density

Energy capacity (Wh) is a more accurate performance metric, calculated as: Voltage (V) × Capacity (Ah) = Energy Capacity (Wh). For example, a 22.2V 12000mAh battery has an energy capacity of 266.4Wh.

Energy density is typically measured in Wh/kg. Current high-end drone batteries achieve 250-280Wh/kg, directly impacting the drone’s endurance and payload capacity.

IV. Drone Battery Discharge Rate: The Key to Power Output

Battery Discharge Rate (C-Rating) Definition and Current Calculation

The discharge rate (C-rating) indicates a battery’s discharge capability, calculated as: Maximum discharge current = Capacity (Ah) × C-rating. For a 10,000mAh battery rated at 20C, the maximum discharge current is 10A × 20 = 200A.

High C-rate batteries suit scenarios requiring burst power, such as racing drones and heavy-load drones, while 15C-25C suffices for standard aerial photography drones.

Internal Resistance and Performance Degradation

Battery internal resistance increases with usage cycles, causing the actual C-rate to decrease. New batteries typically have internal resistance below 10mΩ, which may rise over 50% after 100 cycles.

Regular internal resistance measurements assess battery health. A 25% increase indicates the battery is entering its end-of-life phase.

V. Practical Applications of Drone Batteries: Parameter Selection Guide

Selecting Batteries Based on Drone Type

- Small aerial photography drones (e.g., DJI Mavic series): Typically use 3S-4S intelligent batteries with capacities ranging from 2000-4000mAh

- Industrial-grade drones (e.g., DJI Matrice series): Often utilize 6S-12S configurations with capacities exceeding 10000mAh

- Racing Drones: Require high-C-rate batteries (25C-50C) to support instantaneous high-current discharge

Flight Duration Estimation

Actual endurance is significantly affected by flight speed, payload, and ambient temperature. A conservative estimation formula is: Flight Time (min) = (Battery Capacity × 0.8) ÷ Average Power × 60.

For example, a 266Wh battery at 200W average power consumption yields approximately (266 × 0.8) ÷ 200 × 60 ≈ 64 minutes of flight time.

VI. Key Points for Safe Use and Maintenance of Drone Batteries

Drone Battery Charging Safety Guidelines

Use a balanced charger to ensure consistent voltage across all cells, with differences not exceeding 0.05V. Recommended charging current is 0.5C-1C to prevent rapid charging from causing battery swelling.

Drone Battery Temperature Management

The ideal operating temperature range is 15°C to 35°C. Low temperatures significantly degrade battery performance; preheat batteries in environments below 0°C. In high-temperature conditions, ensure adequate heat dissipation and prevent temperatures from exceeding 60°C.

Drone Battery Storage and Transportation Requirements

For long-term storage, maintain a 50% charge level (3.8V–3.9V) and perform a charge-discharge maintenance cycle every three months. During transportation, provide adequate insulation protection to prevent short circuits.

Mastering drone battery parameters is fundamental to optimizing flight performance. Voltage configuration determines power output, capacity selection impacts endurance, discharge rate affects flight performance, and proper usage and maintenance directly determine battery lifespan.

Users are advised to carefully verify parameter compatibility when purchasing batteries and establish comprehensive battery records during use, documenting capacity and internal resistance changes for each flight. Through scientific management, high-quality lithium polymer batteries can safely cycle over 200 times, providing long-term, reliable power support for drone operations.

As battery technology continues to advance, energy density and safety will steadily improve. Choosing reputable brands, adhering to usage guidelines, and performing regular inspections and maintenance will help you maximize your drone’s performance and enjoy a safe, reliable flying experience.