Customized BMS Solutions for Drone Batteries

The battery BMS system for smart drones enhances battery safety by 300% and extends flight endurance by over 25% through high-precision algorithms and lightweight design.

As lithium battery technology engineers, we understand that the UAV battery BMS (Battery Management System) is the core technology determining flight performance and safety. With the rapid growth of the low-altitude economy, small UAVs have evolved from consumer-grade aerial photography tools to industrial-grade productivity devices. Intelligent BMS is the key to unlocking the full potential of UAVs.

Lingsheng Zhichuang specializes in customized drone battery BMS solutions. We develop high-precision, high-safety, and highly adaptable professional solutions tailored to the unique demands of aerial photography, crop protection, surveying, military applications, and other scenarios. These solutions directly address core challenges facing the drone industry today, including endurance management, lightweight design, thermal management, and extreme environment adaptability.

I. Industry Pain Points Analysis: Technical Challenges Facing Drone Battery BMS

Precision Challenges in Flight Duration and Battery Life Management

Traditional drone battery BMS relies on voltage and current parameters to estimate SOC (State of Charge). However, during sudden acceleration or climb phases, load fluctuations are extreme. The voltage rebound effect can cause SOC calculation errors exceeding 10%. This inaccuracy frequently causes users to experience “sudden power drops” or misjudge flight duration, severely impacting mission planning.

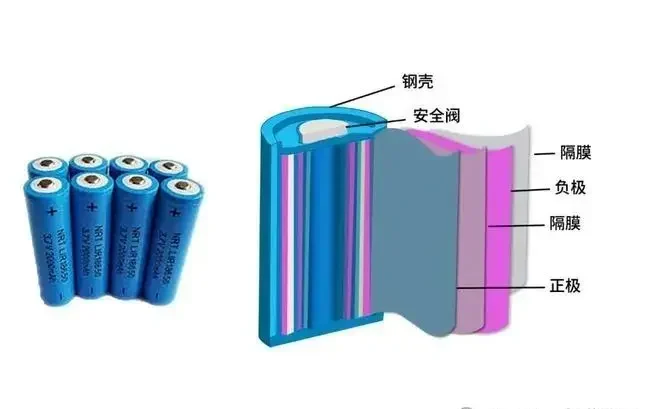

While fast-charging technology reduces charging intervals, if the UAV battery BMS lacks dynamic charging current regulation, it may continue high-current charging during high-temperature or high-SOC phases. This accelerates lithium plating in lithium-ion batteries, causing permanent capacity loss of 20%-30%. During continuous operations, agricultural drone batteries often fail to achieve 800 charge cycles, falling far below theoretical expectations.

The Balance Challenge Between Lightweighting and Integration

Drones are extremely weight-sensitive, with every additional gram potentially impacting flight time and maneuverability. Drone battery BMS must integrate high-precision monitoring, control, and safety protection functions while minimizing weight. Traditional solutions relying on multiple PCBs and discrete components struggle to meet power density requirements.

Industrial-grade drone battery BMS must support high-rate discharges of 10C-50C, while consumer products prioritize cost-to-weight balance. This divergence demands highly flexible BMS design.

Technical Bottlenecks in High-Current and Thermal Management

Industrial drones operating in scenarios like crop protection and logistics must withstand hundreds of amperes of current. Traditional BMS power board designs rely on heat sinks rather than PCB copper foil, and prolonged high-load operation can cause MOSFETs to overheat. Densely packed battery packs exacerbate thermal management challenges, and BMS lacking advanced thermal algorithms struggle to prevent thermal runaway risks.

Insufficient Adaptability to Extreme Environments

Extreme conditions like high altitudes, low temperatures, and strong electromagnetic interference can compromise traditional BMS monitoring accuracy. Battery performance may decline by over 40% below -20°C. If the BMS fails to precisely adjust charging/discharging strategies, it directly increases flight risks.

II. Core Advantages of Horizon BMS Customized Solutions

High-Precision Battery State Monitoring Algorithm

Horizon BMS employs a multi-parameter fusion algorithm that integrates voltage, current, temperature, and internal resistance changes to maintain SOC estimation accuracy within 3%. The system integrates a coulometer chip with an adaptive learning mechanism to calibrate power display in real time, eliminating sudden power drops.

For battery health status, the system establishes a State of Health (SOH) prediction model. By analyzing historical charge/discharge data, it provides early warnings of battery performance degradation, helping users optimize battery replacement cycles.

Lightweight and Highly Integrated Design

Utilizing highly integrated ASIC chips and flexible circuit board technology, the BMS weight is reduced by over 30%. Through structural optimization and material innovation, it meets the stringent weight requirements of drones while maintaining full functionality.

Horizon’s modular design accommodates diverse drone specifications, offering flexible customization from consumer-grade 2S1P configurations to industrial-grade systems exceeding 12S.

Intelligent Thermal Management and High-Current Handling

Innovatively combining temperature field sensing with dynamic current regulation, the system adjusts charging/discharging strategies in real-time via temperature sensors deployed at critical nodes. MOSFETs feature dual-sided heat dissipation design, significantly enhancing stability in high-temperature environments.

The system supports 5C fast charging without compromising battery lifespan, intelligently regulating charging currents to prevent lithium plating during high SOC phases.

Extreme Environment Adaptability Technology

For high-altitude, low-temperature conditions, the BMS integrates self-heating functionality, enabling normal battery startup at -20°C through pulsed current delivery. Electromagnetic compatibility design ensures stable operation in high-interference environments, maintaining voltage monitoring accuracy within ±5mV.

III. BMS Innovation Applications and Performance Breakthroughs

AI-Empowered Intelligent Battery Management

Horizon BMS integrates AI learning algorithms to dynamically adjust battery management strategies based on user flight habits and operational scenarios. By analyzing over 300 parameters, the system achieves fault prediction accuracy exceeding 90%, providing 48-hour advance warnings for battery failures.

Advanced Balancing Technology Extends Battery Lifespan

Utilizing active balancing technology with currents exceeding 300mA, efficiency is boosted fivefold compared to traditional passive balancing. Cell voltage differences within the battery pack are controlled within 0.1V, significantly delaying overall performance degradation.

Multi-Layer Safety Protection Mechanisms

The BMS incorporates hardware-level protection circuits with millisecond-level response times, providing comprehensive safeguards against overcharging, over-discharging, overcurrent, short circuits, and temperature extremes. A dual-loop safety architecture ensures system integrity and continued safe operation even in the event of single-point failures, significantly enhancing reliability.

IV. Customized Solutions for Drone Application Scenarios

Crop Protection Drone-Specific BMS

Optimized for agricultural crop protection scenarios, this BMS enhances sustained high-current discharge capability to support continuous operation under full-load conditions. Designed with corrosion-resistant interfaces and dustproof structures tailored to pesticide spraying characteristics, it withstands harsh field environments.

Surveying and Aerial Photography Drone BMS

Balances endurance precision and weight efficiency, delivering accurate operational time predictions via high-precision SOC algorithms. Supports low-temperature operation to ensure reliable flight at high altitudes.

Military-Grade UAV BMS

Meets MIL-STD-810H military standards, featuring electromagnetic interference resistance and wide-temperature operation (-40°C to 65°C). Integrates secure encrypted communication modules to prevent data leakage.

Tethered UAV Dual-Loop Safety Solution

Employs dual voltage and current loop management, dynamically adjusting output based on maximum cell voltage to prevent overcharging. Supports extended continuous power supply to meet specialized tethered UAV requirements.

V. Future Technological Trends

Intelligent and Predictive Maintenance

BMS will evolve toward predictive maintenance, using big data analytics to identify potential faults in advance. Blockchain technology will enable full lifecycle data traceability for batteries, achieving 98% accuracy in carbon footprint tracking.

Innovations in New Materials and Structures

New materials like graphene aerogel electrodes may accelerate charging speeds to 5C (full charge in 12 minutes). 3D porous structure designs increase electrode surface area by 50 times, boosting both energy and power density.

Enhanced Adaptability Across Environments

Specialized BMS systems resistant to radiation and high pressure will be developed for extreme environments like space and deep sea. Deep integration of solid-state batteries with BMS will further enhance safety and energy density.

Customized BMS solutions for drones are emerging as a key technological enabler for the high-quality development of the low-altitude economy. Through innovations such as high-precision algorithms, intelligent thermal management, and extreme environment adaptability, LingSheng Intelligent Innovation’s BMS system effectively addresses industry pain points including endurance management, lightweight design, thermal challenges, and environmental adaptability.

With the deep integration of AI and BMS, future drone batteries will transition from “passive protection” to “proactive alerts,” delivering safer and more reliable energy support for urban air mobility, logistics delivery, emergency rescue, and other applications.

Selecting a professional BMS customization solution is not only key to enhancing drone performance but also a wise decision for ensuring flight safety, extending battery lifespan, and reducing operational costs. Against the backdrop of a booming low-altitude economy, intelligent BMS technology will continue to propel the drone industry toward safer, more efficient, and smarter development.