Drone Battery Charging Safety Guide

Proper charging habits can extend battery life by up to 300 cycles, while incorrect operation may cause instantaneous loss.

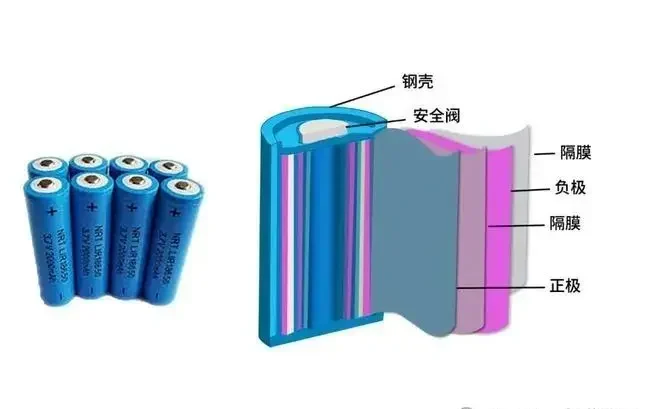

As lithium battery engineers, we understand that drone batteries are the core component of flight systems, with their safety directly impacting flight success and equipment ROI. Lithium polymer (LiPo) and lithium-ion (Li-ion) batteries, favored for their high energy density and lightweight properties, have become the preferred power source for drones. However, this also imposes higher demands on charging safety protocols.

This document systematically analyzes drone battery charging safety protocols to help you establish scientific battery management practices. Adhering to these guidelines not only extends battery life beyond 300 cycles but also effectively prevents safety incidents such as combustion or explosions.

I. Pre-Charging Inspection for Drone Batteries: The First Line of Safety Defense

Device Condition Verification

A comprehensive device inspection must be conducted before charging. First, visually inspect the battery for any swelling, leakage, or deformation, paying particular attention to the integrity of the connectors. Immediately cease use and contact after-sales support if any abnormalities are detected.

Check that the charger’s power cord and plug are undamaged, and ensure connectors are free of dust or oxidation. Wipe the connectors with a dry cloth to guarantee proper contact. The original charger incorporates an intelligent chip that precisely regulates voltage and current, serving as the primary safeguard for safe charging.

Environment Assessment and Preparation

Charge in a well-ventilated, dry, and shaded environment. The ideal temperature range is 5–40°C (41–104°F), with the optimal range being 10–25°C (50–77°F). Avoid charging in high-temperature (>40°C/104°F) or low-temperature (<0°C/32°F) conditions.

Keep the charging area away from flammable or explosive materials (e.g., gasoline, alcohol) and avoid enclosed spaces (e.g., inside vehicles). Use a wall outlet whenever possible to prevent fire hazards from power strip overloads.

II. Choosing a Drone Battery Charger: Compatibility is Key

Principles for Matching Drone Battery Charger Parameters

Voltage matching is a fundamental requirement. The nominal voltage of the drone battery (e.g., 11.1V for a 3S battery) must precisely match the charger’s output voltage. Even chargers with automatic voltage recognition require compatibility verification.

Current matching is equally important. The charger’s output current should be ≥ (Battery Charge Rate (C-rating) × Battery Capacity (mAh) ÷ 1000). For example, a 5000mAh battery requires 5A current for 1C charging; selecting a charger within the 1C-2C range is optimal.

Drone Battery Charger Interface and Protocol Certification

The charger’s physical interface must perfectly match the battery, including outer diameter, inner diameter, and pin definitions. Smart batteries require chargers supporting corresponding charging protocols (e.g., balance charging protocol) to ensure cell equalization.

Prioritize products with 3C certification (China), UL certification (USA), or CE certification (EU). These certifications ensure the charger complies with safety standards including overvoltage protection, overcurrent protection, and short-circuit protection.

III. Drone Battery Charging Procedure: Standardized Operation

Connection Sequence and Indicator Verification

First, plug the charger into a stable power outlet and observe whether the indicator lights illuminate normally (typically red indicates standby). Then correctly install the battery onto the charger, ensuring full contact between the terminals with no looseness.

Upon successful connection, the indicator light turns solid red, indicating charging is in progress. Smart chargers display real-time battery levels or sync status via the app. Balance charging mode is particularly crucial for multi-cell batteries, ensuring consistent voltage across each cell (differences should be ≤0.1V).

Monitoring the Drone Battery Charging Process

Charging must be supervised at all times; unattended charging for extended periods is prohibited. Closely observe the charger and battery status. Immediately disconnect power if any of the following abnormalities occur:

- Temperature exceeding 50°C (122°F) or excessive heat

- Battery swelling, leakage, or unusual noises

- Abnormal indicator light flashing

Lithium batteries must be charged within the specified temperature range (0°C–45°C / 32°F–113°F). Excessive ambient temperatures accelerate battery heating. Immediately stop charging if abnormal surface temperatures are detected.

IV. Post-Charging Procedures for Drone Batteries: Key to Extending Battery Life

Prompt Disconnection and Cooling

Once charging is complete and the indicator light turns solid green (or the app displays 100%), disconnect immediately. Overcharging is strictly prohibited. Leaving the battery connected after full charge increases internal pressure, potentially causing swelling or fire.

After removal, store batteries in a dry, well-ventilated area away from direct sunlight. Avoid immediate use within 30 minutes of charging completion to ensure thorough cooling.

Long-Term Storage Strategy

If batteries remain unused for over 10 days, discharge them to 40%-60% capacity before storage. Storing at full charge or depleted levels accelerates battery degradation. Maintain ideal storage temperatures between 15°C-25°C in a dry, light-protected environment.

Check stored battery voltage every 2-3 months. If voltage falls below 3.0V per cell, recharge to the storage voltage range (3.7V-3.8V per cell). Regularly monitor cycle count and capacity decay using a battery health management app.

V. Special Environmental Strategies for Drone Battery Charging

Techniques for Charging Drone Batteries in Low-Temperature Environments

Winter cold significantly reduces battery performance. Preheat the battery to above 20°C before charging (some models support automatic heating). Battery capacity may decrease by 20%-30% in low temperatures, requiring additional return-to-base power reserves.

Avoid charging in extreme cold (<-10°C). Allow the battery to recover to above 5°C before charging.

Protective Measures for Charging Drone Batteries in High-Temperature Environments

Exercise extreme caution when charging in high-temperature environments (>35°C). Avoid charging during midday heat; instead, charge in the early morning or evening. Use heat sinks or portable fans to assist cooling during charging, ensuring battery temperature does not exceed 60°C.

VI. Drone Battery Charging Safety Standards and Emergency Procedures

Battery Retirement Criteria

Immediately discontinue use when batteries exhibit any of the following conditions:

– Cycle count exceeds 200 cycles with capacity below 80%

– Internal resistance > 5mΩ (measurable via professional testing equipment)

– Noticeable swelling, leakage, or abnormal voltage

Emergency Response Protocol

If a battery emits smoke or catches fire, extinguish it using copious amounts of water, sand, or a dedicated fire extinguisher. Never use dry powder extinguishers, as they may corrode the device. Isolation and suffocation are effective methods for dealing with lithium battery fires.

Swollen batteries must be safely discharged to 0V before professional recycling. Disposal is strictly prohibited. Some brands offer trade-in programs for old batteries when purchasing new ones, providing an environmentally responsible disposal option.

VII. Industry Standards and Compliance Requirements

Safety Certification System

Drone batteries must comply with multiple safety standards, such as UN38.3 transport certification and regional mandatory certifications (CE/CCC). Starting August 2024, China will implement mandatory CCC certification for drone batteries.

National Standard GB 42590-2023 specifies explicit drop safety requirements for drone batteries: Batteries must not explode or ignite after a 10-meter free fall (at 30% ± 2% charge).

Performance Testing Standards

Premium drone batteries must pass compression testing (13kN pressure for 10 minutes without ignition or leakage), short-circuit protection testing (response time < 1 second, temperature < 150°C), and cycle life testing (capacity retention ≥ 80% after 500 cycles).

Below is a core safety parameter comparison table:

| Test Items | Test Method | Criteria for Determination |

|---|---|---|

| Overcharge Protection | Charge at 1C current to 1.5 times the rated voltage. | BMS response ≤ 200 ms, no fire or explosion |

| Short-circuit protection | Direct short circuit between positive and negative terminals (≤50 mΩ) | Protection action < 1 second, temperature < 150°C |

| Compression test | 13 kN pressure maintained for 10 minutes | Non-flammable, non-leaking |

| Flame Retardant Testing | Expose the battery compartment to a 1000°C flame for 30 seconds. | Self-extinguishing time ≤ 3 seconds |

Drone battery charging safety is the cornerstone of flight operations. Through rigorous pre-charge inspections, selection of matched chargers, standardized charging procedures, and scientific post-charge maintenance, battery safety can be significantly enhanced and service life extended.

Key safety points include: always using original chargers, maintaining supervision during charging, avoiding overcharging and over-discharging, managing temperature, and conducting regular health checks. Establishing battery usage records and tracking each charge/discharge cycle enables early warning of potential risks.

As the low-altitude economy flourishes, drone battery safety management will become a focal point for the industry. Selecting compliant products, adhering to professional guidelines, and establishing scientific habits represent best practices for ensuring flight safety and efficiency.