Preventing and Mitigating Drone Battery Life Degradation

Proper battery management can extend a drone battery’s cycle life from 300 to 1,000 cycles while maintaining over 85% capacity retention.

As lithium battery engineers, we understand that drone battery life degradation is a core pain point affecting flight experience. Through scientific battery management strategies, battery lifespan can be extended by 2-3 times, significantly reducing operational costs. This article analyzes the mechanisms behind preventing drone battery life degradation from a technical perspective and provides practical solutions.

Statistics indicate that approximately 65% of drone failures are directly linked to improper battery usage. Properly maintained batteries can retain 85% capacity after 1,000 cycles, whereas carelessly used batteries become unusable after just 300 cycles, with capacity degraded to 60%. This means a single battery costing ¥2,000 can save ¥4,000 in replacement costs over two years with correct usage.

I. Precision Charging Strategy: Delaying Battery Degradation at Its Source

The Irreplaceability of Original Chargers

Using the original charger is not only a brand requirement but a technical necessity. Chargers of different brands and models exhibit varying output voltage and current characteristics. Non-original chargers may cause overcharging or undercharging of the battery. Taking DJI drones as an example, the original charger incorporates an intelligent chip that precisely controls the charging curve, ensuring balanced charging for each cell.

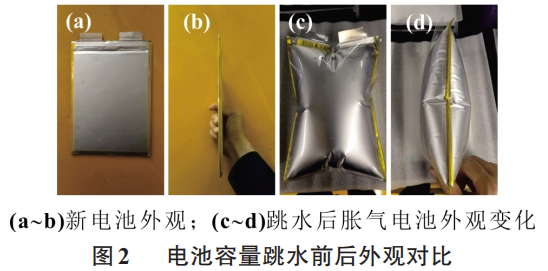

The charging cutoff voltage for lithium polymer batteries is 4.2V per cell. Continuing to charge beyond this threshold causes electrolyte decomposition and gas buildup, leading to swelling. The overcharge protection feature in original chargers effectively prevents voltage from exceeding this safety threshold.

Optimal Charging Range and Battery Health

Maintaining battery levels between 20% and 80% represents the optimal charging strategy. When the battery level drops below 20%, charge it promptly; unplug the charger immediately after full charge. After each flight, if the battery retains around 30% charge, recharge it to 70%-80% before the next flight.

High-charge storage is the primary cause of battery degradation. Storing a fully charged battery for 3 months increases the risk of swelling by 5 times compared to storing it at 40% charge. The intelligent self-discharge function of drone batteries (e.g., automatically discharging to 96% after 3 days and 60% after 9 days when fully charged) is a crucial protective mechanism.

Impact of Temperature on Charging Efficiency

Maintaining charging temperatures between 15°C and 25°C is ideal. Below 5°C, lithium-ion insertion into the anode slows, increasing the risk of lithium dendrite formation on the surface, which can pierce the separator and cause short circuits. At temperatures above 40°C, electrolyte decomposition accelerates and the SEI (Solid Electrolyte Interphase) film thickens, resulting in loss of active lithium and increased internal resistance.

Avoid charging in direct sunlight inside vehicles during summer. After outdoor use in winter, allow the battery to return to room temperature before charging. Some high-end drone batteries feature built-in heating systems that automatically preheat to 16-20°C in cold environments.

II. Scientific Storage Methods: Maintaining Long-Term Battery Activity

Storage Capacity and Environmental Control

For long-term storage, maintain the battery charge between 40% and 60%. Storing at full charge accelerates electrode oxidation and electrolyte decomposition, while storing with a low charge may cause dissolution of the negative copper current collector. Batteries not in use for over a month should be discharged to approximately 50% before storage.

Store in a cool, dry environment with an ideal temperature range of 15°C–25°C. High temperatures accelerate self-discharge: capacity degrades by 15% annually at 25°C versus only 5% at 5°C. Humidity may cause corrosion at battery terminals, increasing contact resistance.

Regular Maintenance and Health Checks

Perform deep maintenance every 50 cycles or every three months. Maintenance includes: balancing cell voltages, calibrating capacity, and maintaining battery activity. During maintenance, check:

- Whether cell voltage difference is less than 0.1V

- Whether battery firmware is the latest version

- Whether there is swelling, leakage, or damage

For long-term storage, perform one charge-discharge cycle monthly to maintain activity. Using the pulse charging mode of professional equipment (such as HOTA D6 Pro) can eliminate lithium dendrites on electrode surfaces through high-frequency pulses, enhance ion migration efficiency, and increase cycle life by 30%.

III. Flight Optimization Techniques: Reducing Actual Energy Consumption

Smooth Operation and Flight Planning

Maintaining smooth operation significantly reduces energy consumption. Frequent acceleration, deceleration, and sharp turns cause the drone to consume large amounts of power instantaneously. Flying at a constant speed extends flight time by over 20% compared to abrupt maneuvers.

Proper flight planning is crucial. At -10°C (-14°F), battery capacity drops by over 40%. A battery capable of 30 minutes at room temperature may only last 18-21 minutes in winter. Initiate forced return when battery level falls below 30% to maintain safety margins.

Environmental Adaptation and Temperature Management

Avoid harsh conditions like strong winds and low temperatures. High winds increase flight resistance, forcing motors to expend more energy to maintain stability. Crosswinds exceeding Force 6 can cause attitude instability and heighten crash risk.

Preheating batteries in cold environments is essential. Optimal preheating to above 20°C (68°F) before flight is recommended. Use insulated bags or professional preheaters; some industrial-grade drones feature built-in heating systems that automatically maintain battery temperature. Preheating can increase capacity retention from 50% to 82%.

Load Control and Equipment Optimization

Manage drone payload weight appropriately. Additional loads increase motor strain, leading to higher discharge currents. As internal resistance increases, battery heat generation rises quadratically (P=I²R), accelerating battery degradation.

Regularly inspect propeller balance and motor smoothness. Propeller cracks or motor debris jams increase power consumption, placing additional strain on the battery. Maintaining equipment in optimal condition reduces energy consumption per unit flight time.

IV. Advanced Maintenance Plan: For Special Scenarios

Customized Strategies for Different Usage Scenarios

For high-frequency racing (flying >10 times weekly), we recommend installing a water-cooling kit to rapidly cool the battery to below 30°C after flights. Adopt the “30-70” charging method (charging only to 70%) to reduce electrode stress.

In high-altitude, low-temperature environments (elevation >3000m), use a pressure-resistant battery compartment to maintain internal pressure at 1.2atm, preventing lithium plating at low temperatures. Pair with battery preheating pads to raise temperature to 15°C within 5 minutes.

After flights in marine salt spray environments, apply silicone grease to connectors and spray nano-waterproof coating on the casing. Rinse the battery compartment daily with fresh water and monitor corrosion risks.

AI and Intelligent Battery Management

Modern smart batteries support AI predictive management. By recording voltage, temperature, and internal resistance curves during each charge/discharge cycle, they forecast remaining cycle life and identify potential failure points. For example, electrolyte depletion can be predicted 7 days in advance, preventing sudden power loss during flight.

Digital twin technology enables the creation of software-based battery models to simulate performance degradation under various usage scenarios and evaluate the effectiveness of different maintenance strategies. This virtual testing aids in identifying optimal maintenance protocols.

The following table summarizes battery performance comparisons across different maintenance levels:

Battery life degradation in drones is preventable and controllable. By implementing precise charging strategies, scientific storage methods, and optimized flight techniques, battery lifespan can be significantly extended while reducing operational costs.

Key measures include: using original chargers, maintaining a storage charge level between 40-60%, avoiding operation in extreme temperatures, and conducting regular health checks. Implementing these measures not only mitigates degradation but also enhances flight safety.

It is recommended to establish a battery health log, recording data from each cycle. When battery capacity drops to 80% of its initial value or internal resistance increases by 25%, consider downgrading usage or replacement. Scientific battery management is the cornerstone of efficient drone operations and deserves the attention of every professional pilot.