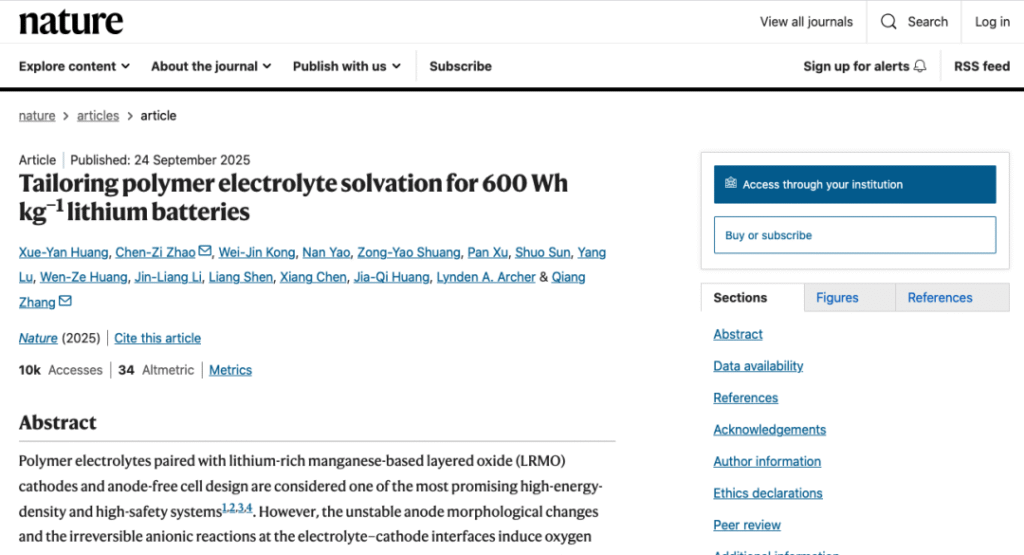

Breakthrough in Drone Battery Flight Duration! Tsinghua’s Solid-State Battery Advances Published in Nature, Achieving Energy Density Exceeding 600 Wh/kg

An industrial-grade drone takes off smoothly in sub-zero temperatures of -20°C and maintains ample power after two hours of continuous flight—this is no longer a conceptual video, but the imminent reality envisioned by drone solid-state battery technology.

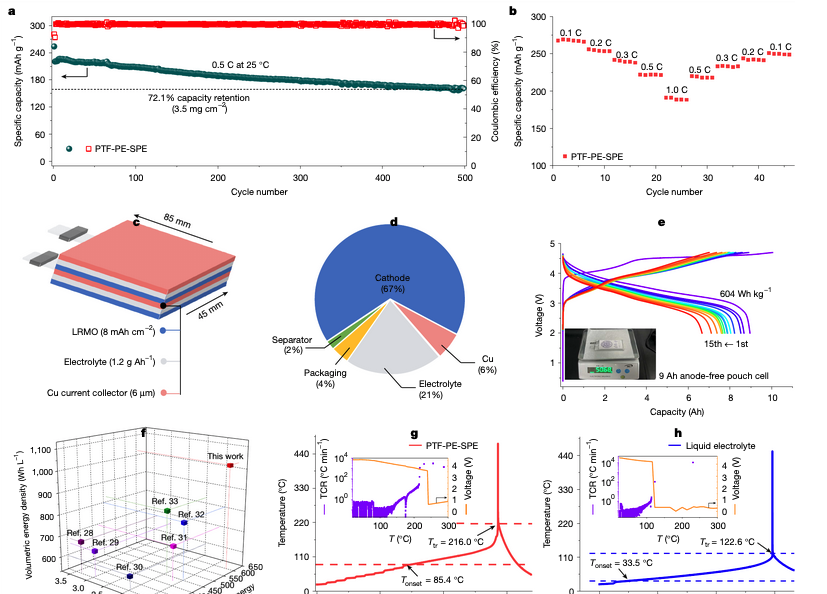

Recently, Professor Zhang Qiang’s team from Tsinghua University’s Department of Chemical Engineering published a major breakthrough in drone solid-state battery research in Nature. They developed a novel fluorinated polyether electrolyte, achieving a weight energy density of 604 Wh/kg and a volume energy density as high as 1027 Wh/L.

These figures exceed the energy density of current high-end commercial batteries by more than double, signaling a potential leap in endurance for drones, electric aircraft, and similar devices.

Crucially, this technology simultaneously addresses the industry’s longstanding challenge of balancing high energy density with safety, providing a clear technical pathway for next-generation high-safety, high-energy-density solid-state lithium batteries.

I. Technological Breakthrough: Solving Core Challenges in Solid-State Batteries

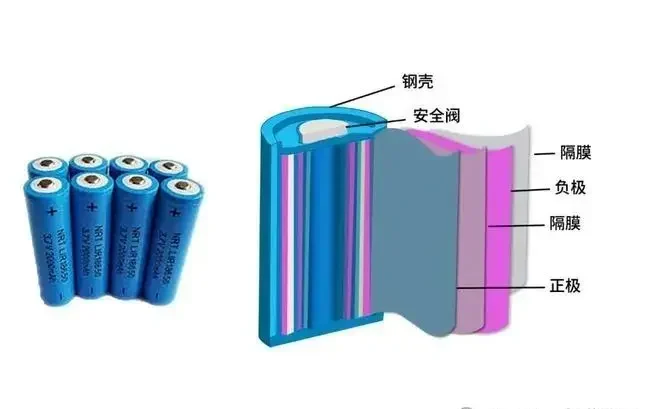

Solid-state batteries are hailed as a pivotal development direction for next-generation rechargeable lithium batteries. Their high energy density and inherent safety potential hold revolutionary significance, particularly in weight-sensitive applications like drones.

However, solid-state batteries have long faced two major technical bottlenecks in practical implementation:

First, poor interface contact resulting from rigid contact between solid-solid materials;

Second, the electrolyte’s inability to simultaneously accommodate the extreme chemical environments of high-voltage cathodes and strongly reductive anodes across a wide voltage window.

Addressing these challenges, Professor Zhang Qiang’s team proposed an innovative “anion-rich solvation structure” design strategy, successfully developing a novel fluorinated polyether electrolyte.

By introducing strongly electron-withdrawing fluorinated groups into the polyether backbone, the electrolyte’s high-voltage oxidation resistance was significantly enhanced, enabling compatibility with 4.7V high-voltage lithium-rich manganese cathodes.

Simultaneously, the polymer’s unique “–F∙∙∙Li⁺∙∙∙O–” coordination structure effectively induces the formation of anion-rich solvation structures. This, in turn, generates a stable fluoride-rich interfacial layer on the electrode surface, substantially enhancing interfacial stability.

The team employed thermal-initiated in-situ polymerization technology, injecting liquid monomer precursors into the battery interior. Heating then triggered polymerization reactions, directly forming solid electrolytes on electrode surfaces.

This method creates seamless, tightly bonded interfaces between electrolyte and electrodes, eliminating the porosity and high interfacial impedance issues common in conventional pre-fabricated solid electrolytes.

II. Performance Breakthroughs: Dual Advancements in Energy Density and Safety

Using this novel fluorinated polyether electrolyte, the research team constructed a high-capacity 8.96Ah polymer pouch cell.

Under 1MPa external pressure, the battery achieved a weight energy density of 604Wh/kg and a volume energy density as high as 1027Wh/L.

What do these figures signify? Top-tier commercial electric vehicle battery packs currently offer energy densities around 255Wh/kg, while this novel solid-state battery delivers over twice that density.

For the drone industry, this breakthrough is even more revolutionary. Most commercial drone batteries currently operate within an energy density range of 150-250 Wh/kg.

Adopting batteries exceeding 600 Wh/kg could potentially double drone flight times, fundamentally resolving the current major bottleneck in drone applications.

Beyond energy density, the battery’s cycle life is equally encouraging. At a 0.5C discharge rate, it maintained 72.1% of its capacity after 500 cycles, demonstrating outstanding long-term stability.

By comparison, batteries using traditional polymer electrolytes degrade to 80% capacity after just 50 cycles.

Safety stands out as another major advantage of this solid-state battery. When fully charged, it successfully passed both needle penetration and 120°C thermal box tests (held for 6 hours) without combustion or explosion.

The electrolyte itself possesses flame-retardant properties, and the final PTF-PE-SPE electrolyte membrane is completely non-flammable, fundamentally eliminating the risk of thermal runaway in lithium batteries.

III. Revolutionary Impact on the Drone Industry

Dual Enhancement of Flight Duration and Payload Capacity

Ultra-high energy density directly translates into extended flight endurance for drones. Industrial-grade drones are poised to achieve over 2 hours of flight time, representing a 30%-40% improvement over traditional batteries.

Simultaneously, operational range and payload capacity will increase in tandem, eliminating the current drone dilemma of “30 minutes of flight followed by 2 hours of charging.” This will significantly boost operational efficiency.

Leap in Safety and Reliability

Non-flammable solid electrolytes fundamentally eliminate fire and explosion risks, making drones safer and more reliable for high-risk applications such as agricultural spraying (pesticide environments), chemical plant inspections (flammable/explosive scenarios), and firefighting/rescue operations (high-temperature conditions).

Enhanced Adaptability to Extreme Environments

The battery’s wide temperature range performance (-20°C to 60°C stable operation) resolves issues of “difficult startup and performance degradation” in high-altitude and frigid regions.

Previously, the all-weather high-energy-density drone battery developed by the Dalian Institute of Chemical Physics maintained over 88% capacity retention at -40°C, demonstrating excellent low-temperature performance.

Tsinghua’s new technology further expands the battery’s operational temperature range, significantly broadening the geographical boundaries for drone applications.

Significantly Enhanced Operational Efficiency

Combined with fast-charging technology, future drones may achieve an efficient operational model of “10-15 minutes of charging for 1 hour of flight,” substantially improving operational availability.

Additionally, eliminating the need for heavy external pressurization equipment contributes to a lighter power system, further boosting the overall energy efficiency of the drone.

IV. Enabling Entirely New Application Scenarios

Fundamental breakthroughs in battery technology will unlock entirely new market opportunities previously beyond the reach of drones:

Long-Endurance Logistics Networks

The combination of doubled endurance and high safety enables automated logistics delivery over medium-to-long distances exceeding 150 kilometers between mountainous regions and islands, effectively solving the “last hundred kilometers” transportation challenge in remote areas.

High-Level Emergency Rescue

Drones can penetrate fire and earthquake epicenters, performing continuous reconnaissance, communication relay, and supply delivery for hours—serving as the “aerial lifeline” for rescue teams rather than merely short-range “flying cameras.”

High-End Specialized Applications

Providing stable power for stratospheric aircraft and deep-sea probes, these advancements propel scientific exploration and defense applications toward deeper, higher, and farther frontiers.

The all-weather high-energy-density drone battery technology previously developed by the Dalian Institute of Chemical Physics, Chinese Academy of Sciences, has achieved a mass energy density exceeding 500 Wh/kg, maintaining excellent high-power output performance even in sub-zero temperatures of -40°C.

Tsinghua University’s new technology further enhances energy density and safety on this foundation, laying the groundwork for broader specialized applications.

Looking ahead, the breakthrough in Tsinghua’s solid-state batteries—transitioning from laboratory research to industrial application—represents not only an advancement in battery technology but also an upgrade to the “core engine” of the low-altitude economy.

This innovation transforms drones from “agile yet fragile” tools into “reliable and efficient” automated platforms, unlocking their immense potential in logistics, rescue operations, scientific research, and specialized missions.

As this technology moves from the laboratory to industrialization, the wave of a drone power revolution is quietly emerging.