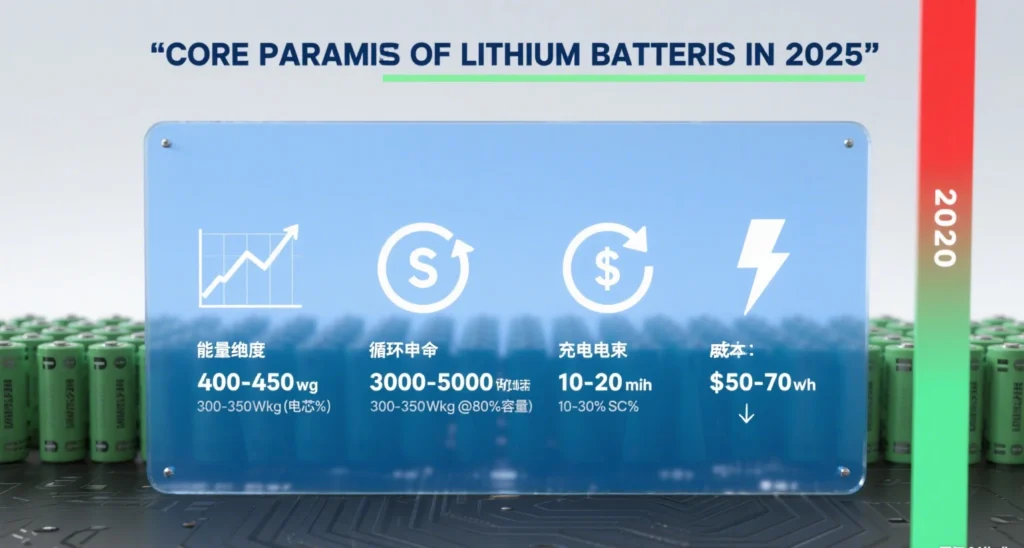

Core Parameters of Lithium Batteries in 2025

Mastering 11 Key Parameters for Precise Selection and Optimization of Lithium Battery Solutions

As lithium battery engineers, we understand the critical importance of parameter comprehension for battery selection and system design. This article systematically analyzes the 11 core parameters of lithium batteries in 2025, helping you gain a comprehensive understanding of battery performance metrics and providing professional guidance for project selection.

I. Lithium Battery Voltage Parameters: The Energy Potential of Batteries

Lithium battery voltage refers to the potential difference between the battery’s positive and negative electrodes, measured in volts (V). This parameter determines the “driving force” for electron flow within a circuit, directly influencing a device’s power output capability.

Different types of lithium batteries exhibit distinct operating voltage ranges:

- Ternary Lithium Batteries: 2.8V–4.2V, nominal voltage 3.7V

- Lithium Iron Phosphate Batteries: 2.5V–3.65V, nominal voltage 3.2V

- Lithium Cobalt Oxide Batteries: 3.0V–4.2V, nominal voltage 3.7V

In practical applications, the nominal voltage serves as the foundation for calculating system voltage. For instance, electric vehicle battery packs achieve the required operating voltage by connecting multiple cells in series, typically forming 400V or 800V platforms.

II. Lithium Battery Capacity and Energy: Determinants of Range

Lithium battery capacity (Ah or mAh) indicates the battery’s ability to store electrical charge, analogous to the volume of a fuel tank. Capacity determines how long a device can operate on a single charge.

Energy (Wh) is the product of capacity and voltage, representing the total energy stored in the battery. The calculation formula is:

Energy (Wh) = Capacity (Ah) × Voltage (V)

For example, the Tesla Model 3 Long Range battery pack has a capacity of 230Ah and a voltage of 350V, yielding a total energy of 80.5kWh. This provides a NEDC range of 668 kilometers.

III. Lithium Battery Rate Performance: A Key Indicator of Power Output

The rate (C-rate) represents the ratio of charge/discharge current to battery capacity, serving as a critical parameter for evaluating battery power performance. The calculation formula is:

Charge/Discharge Current (A) = Capacity (Ah) × Rate (C)

Different application scenarios exhibit significant variations in rate requirements:

- Consumer Electronics: Typically 0.5C–1C, meeting everyday usage needs

- Power Tools: Requires 10C–20C for instantaneous high-power output

- Electric Vehicles: 3C–5C satisfies acceleration and fast-charging demands

- Drones & RC Models: Demands 15C–30C high-rate performance

When customizing lithium-ion 4680 batteries, rate characteristics are a critical parameter to prioritize—especially for high-power applications.

IV. Lithium Battery Internal Resistance Characteristics: Foundation for Efficiency and Thermal Management

Internal resistance refers to the resistance value within a battery, typically measured in milliohms (mΩ). It impacts both energy efficiency and thermal management design:

- Energy Loss: Internal resistance causes I²R losses, reducing system efficiency

- Temperature Rise Control: Heat generated by internal resistance during high-current operation requires effective management

- Consistency Requirement: Cell internal resistance variation within a battery pack should be less than 3 mΩ

Internal resistance measurement requires specialized equipment, such as AC internal resistance testers; standard multimeters cannot provide accurate readings.

V. Lithium Battery Cycle Life and Durability

Cycle life refers to the number of complete charge-discharge cycles a battery undergoes before its capacity degrades to 80% of its nominal capacity. Influencing factors include:

- Material System: Lithium iron phosphate > ternary > lithium cobalt oxide

- Operating Temperature: Longest lifespan at 25°C; accelerated aging at high temperatures

- Depth of Discharge: Shallow charge/discharge cycles extend lifespan

- Charge Rate: High-current charging accelerates capacity decay

Typical Cycle Life Ranges:

- Consumer Electronics: 300–500 cycles

- Power Batteries: 1000–2000 cycles

- Energy Storage Systems: 3000–6000 cycles

VI. Lithium Battery Temperature Characteristics: Environmental Adaptability Considerations

The operating temperature range of lithium batteries directly impacts their application scenarios:

- Charging Temperature: 0°C–45°C (Low-temperature charging may cause lithium plating)

- Discharging Temperature: -20°C–60°C (Capacity degradation occurs at low temperatures)

- Storage Temperature: -20°C–25°C (High temperatures accelerate self-discharge)

In practical design, appropriate battery types and thermal management solutions must be selected based on the application environment.

VII. Lithium Battery Safety Parameters: The Bottom Line in System Design

Lithium battery safety parameters are critical, including:

- Overcharge Tolerance: Typically 110%-120% of nominal voltage

- Over-Discharge Protection: Prevents irreversible damage from excessively low voltage

- Short-Circuit Protection: Instantaneous high currents may trigger thermal runaway

- Thermal Stability: Material decomposition temperature determines safety margin

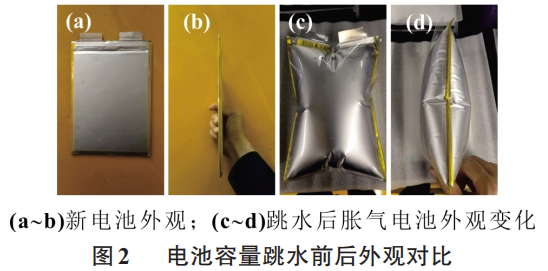

VIII. Lithium Battery Consistency Requirements: Foundation for Pack Applications

Battery pack performance depends on cell consistency, with key parameters including:

- Voltage consistency: ΔV ≤ 5mV

- Internal resistance consistency: ΔR ≤ 3mΩ

- Capacity consistency: ΔC ≤ 1%

- Temperature consistency: ΔT ≤ 2℃

Packs with poor consistency exhibit the bucket effect, where overall performance is limited by the weakest cell.

IX. Lithium Battery State of Charge (SOC) Estimation

SOC represents the percentage of remaining charge, and accurate estimation poses challenges:

- Voltage Method: Simple but inaccurate, highly influenced by load

- Ah Integration: Requires precise current measurement and initial SOC

- Kalman Filtering: Combines multiple parameters for high accuracy but complexity

- Impedance Spectroscopy: Derives SOC from AC impedance with high precision

X. Battery Management System Requirements

The BMS is a critical component of the battery pack, responsible for:

- Status Monitoring: Real-time monitoring of voltage, current, and temperature

- Balancing Management: Active or passive balancing to ensure consistency

- Protection Functions: Overcharge, over-discharge, overcurrent, and overtemperature protection

- Communication Interface: Data exchange with the host system

XI. Lithium Battery Application Selection Guide

Select the appropriate battery type based on application requirements:

High Energy Density Applications (Consumer Electronics, Laptops):

- Prefer lithium cobalt oxide or ternary batteries

- Focus on weight energy density and volumetric energy density

High-power applications (power tools, drones):

- Require high-rate ternary or lithium iron phosphate batteries

- Prioritize internal resistance and thermal management

Long-life requirements (energy storage systems, electric vehicles):

- Prefer lithium iron phosphate batteries

- Focus on cycle life and capacity decay rate

Wide-temperature applications (outdoor equipment, automotive starting):

- Require wide-temperature electrolyte formulations

- Consider heating and cooling system requirements

For specialized applications such as customizing 4680 lithium-ion batteries, comprehensively evaluate energy density, power characteristics, safety requirements, and cost factors to select the most suitable cell type and packaging solution.