Evolution of Cylindrical Battery Sizes and Technological Breakthroughs

Behind millimeter-level changes in battery dimensions lies a systemic interplay of energy density, thermal management, safety, and cost-effectiveness.

As lithium battery engineers, we understand that selecting cylindrical battery dimensions is far from a simple “bigger is better” approach. From the 18650 to the 21700, and now the latest 4680, each dimensional evolution represents a comprehensive balancing act between capacity, power, safety, and cost.

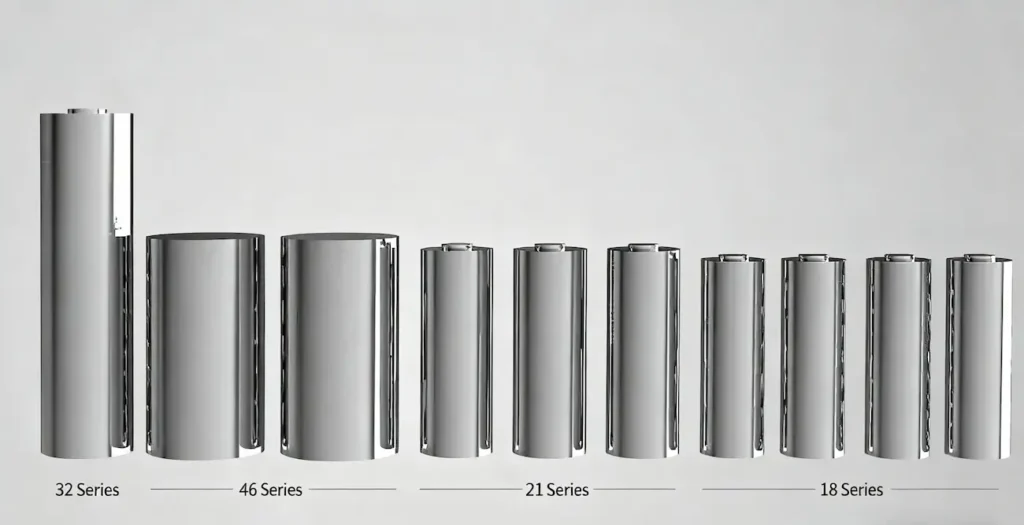

Cylindrical battery model names directly reflect their physical dimensions: the first two digits indicate diameter (mm), the middle two denote height (mm), and the trailing “0” signifies a cylindrical shape. For example, 18650 represents a 18mm diameter, 65mm height cylinder, while 4680 denotes a 46mm diameter, 80mm height battery.

I. The Positive Correlation Between Cylindrical Battery Dimensions and Capacity/Energy

Under identical chemical systems and technological levels, cylindrical battery dimensions exhibit a strong positive correlation with capacity. Larger dimensions accommodate more active materials (anode/cathode materials, electrolyte), directly increasing battery capacity.

From 18650 to 21700, the capacity of a single cell increased by approximately 35%, with energy density rising by over 20%. The 4680 battery takes this further, delivering a fivefold increase in energy, a sixfold increase in power output, and a 16% increase in driving range.

This energy leap stems not only from physical enlargement but also from material system upgrades enabled by larger dimensions. Expanded internal space allows engineers to incorporate high-performance materials like silicon-carbon anodes (theoretical specific capacity of silicon-based materials reaches 4200mAh/g, over ten times that of graphite) while supporting high-nickel cathodes (e.g., NCM811, NCA), achieving a quantum leap in energy density.

II. The Decisive Influence of Cylindrical Battery Diameter on Power Characteristics

Battery power performance (rapid charging and discharging capability) primarily depends on the effective surface area of the electrodes and the ion migration path. Increasing the diameter directly widens the electrode sheet, significantly expanding the contact area between positive and negative electrodes while reducing current density and internal resistance.

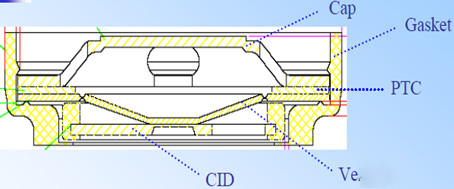

The full-tab (tabless) design adopted by the 4680 battery is key to its breakthrough power performance. While traditional 18650 batteries feature an electronic conduction path as long as 800-1000mm, the 4680 battery reduces this distance to the battery height (approximately 80mm). Internal resistance drops from about 20mΩ to 2mΩ, a nearly tenfold reduction.

This low internal resistance enables the 4680 battery to support 6C ultra-fast charging, delivering a charge from 10% to 80% in just 9 minutes. This innovation fundamentally resolves range anxiety for electric vehicles.

III. Thermal Management Challenges and Innovative Solutions for Cylindrical Batteries

As battery dimensions increase, thermal management complexity significantly escalates. Higher capacity yields greater heat generation, while the inherent thermal characteristics of cylindrical structures pose severe thermal challenges for large-diameter batteries.

The 4680 battery addresses heat dissipation through multiple innovations:

- The full-tab design not only reduces internal resistance and heat generation but also provides a larger heat dissipation surface area.

- System-level thermal optimization employs a bottom cooling plate design, replacing traditional inter-cell heat dissipation structures

- Innovative structural designs like TALAN New Energy’s “Cold Core Battery” utilize a through-core structure, creating direct heat dissipation pathways to the cell center

These innovations reduce heat generation by 30% compared to traditional designs under 1C discharge conditions, resolving thermal management challenges for large cylindrical batteries.

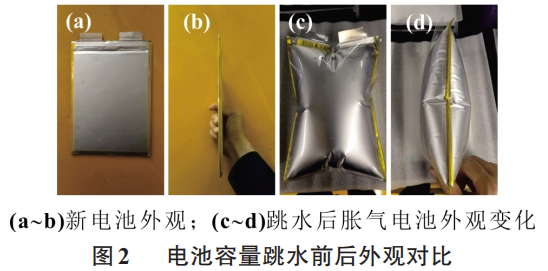

IV. The Art of Balancing Safety and Size

Safety is the bottom line in battery design. Larger battery cells can accommodate more active materials, leading to more intense energy release during thermal runaway. Cylindrical batteries, with their curved surfaces and line contact characteristics, inherently limit thermal propagation to some extent.

The 4680 battery enhances safety through multiple approaches:

- Structural Safety: The cylindrical shape distributes internal forces evenly, better accommodating the high expansion of silicon-based anodes.

- System Safety: Significantly reduces cell count (from over 7,000 in 18650 cells to 960), simplifying BMS management

- Material Safety: Compatible with more stable material systems like lithium iron phosphate (LFP) or lithium manganese phosphate (LMP)

These designs enable the 4680 battery to maintain high energy density while passing more stringent safety tests.

V. Economic and Technical Considerations in Cylindrical Battery Size Selection

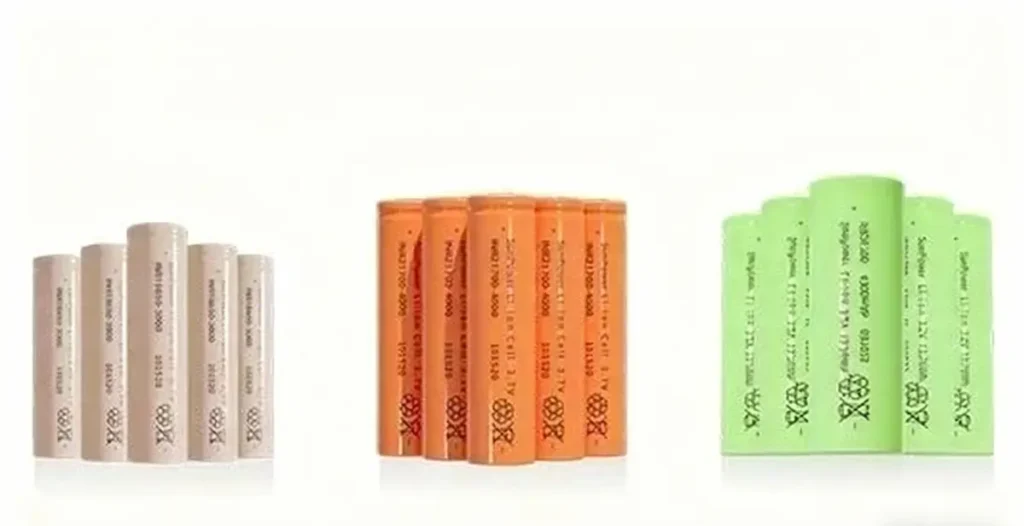

Battery size selection is not merely a technical issue but also an economic one. Standardized sizes (e.g., 18650) offer significant cost advantages due to massive mass production scales. New formats (e.g., 4680) require investment in new equipment and production lines, resulting in higher initial costs.

However, from a system-level perspective, 4680 batteries can reduce overall costs:

- – 14% reduction in system cost per kWh compared to 21700

- – 69% decrease in investment cost per GWh

- – Simplified battery pack structure with fewer connectors and structural components

Innovations like dry electrode processes further lower costs:

- – Over 20% reduction in production costs

- – Over 35% decrease in investment costs

- – Over 70% reduction in electrode production footprint

VI. Application Scenarios Determine Size Selection

Different application scenarios have distinct battery size requirements:

Consumer Electronics (Bluetooth Earbuds, Smartwatches): Opt for micro cells with diameters <10mm, prioritizing volumetric energy density and safety.

Portable Devices (Laptops, Power Tools): Utilize 18650 or 21700 batteries, balancing capacity and portability.

Electric Vehicles:

Trend toward larger formats like 4680 to meet high energy, high power, and high safety demands. BMW adopts the 4695 size, while Tesla drives 4680 standardization.

Energy Storage Systems:

May utilize larger cylindrical cells (e.g., 46120) to further reduce system costs.

VII. Future Trends: Size Standardization and Performance Breakthroughs

Cylindrical battery development is advancing in two directions: size standardization and performance maximization. The 46-series large cylindrical batteries are projected to capture over 30% of the global power battery market share by 2030.

Future technological innovations will focus on:

- Optimization of Full-Tab Processes: Addressing tab collection challenges to enhance production efficiency

- Widespread Adoption of Dry Electrode Technology: Achieving mass production breakthroughs in dry cathode electrodes

- Material System Innovation: Application of high-nickel cathodes, silicon-carbon anodes, and solid-state electrolytes

- System Integration Innovation: Further integration of batteries and vehicle bodies through CTC (Cell to Chassis) technology

These innovations will drive cylindrical batteries to continuously push performance boundaries while maintaining cost advantages.

The dimensional evolution of cylindrical batteries represents a systemic engineering revolution from 18650 to 4680, extending far beyond mere physical size changes. The 46mm diameter has proven to be the optimal solution balancing performance and cost-effectiveness at current technological levels, while innovations like full-tab technology and dry electrode processes have addressed power and thermal management challenges in larger-sized batteries.

Looking ahead, advancements in materials science and manufacturing processes will drive further breakthroughs in high energy density, ultra-fast charging, and enhanced safety for cylindrical batteries. These innovations will deliver superior solutions for new energy vehicles and energy storage systems. As lithium battery engineers, we anticipate witnessing China’s battery companies transition from followers to rule-makers in global technological competition, propelling the entire industry toward greater efficiency, safety, and cost-effectiveness.