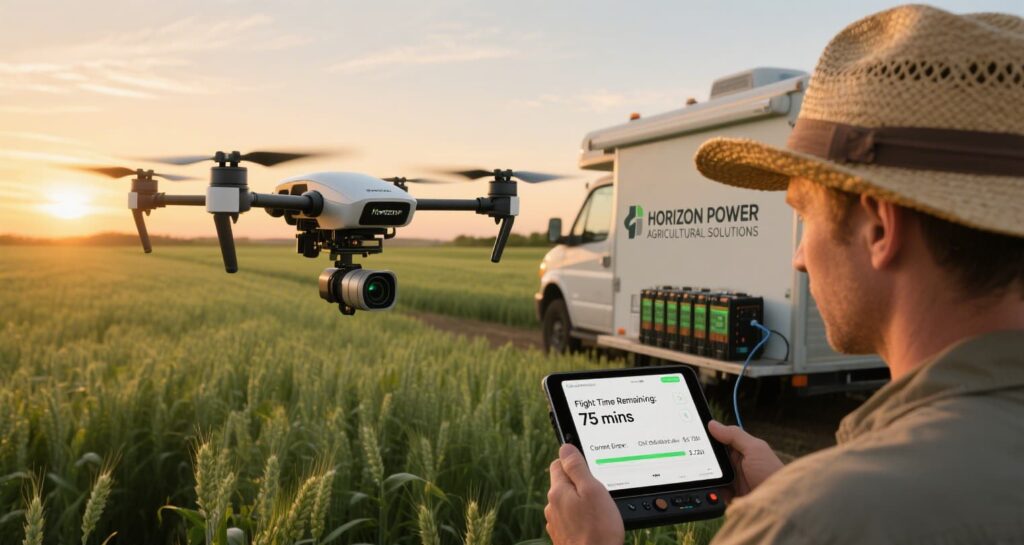

Horizon Power High-Capacity Semi-Solid Battery Products for UAVs

Combining high energy density and excellent safety, it provides strong power support for industrial drones

In the era of technology-driven industrial change, drone lifting and transportation is becoming a key force to break through the limitations of traditional transportation modes. The launch of Horizon Power’s high-capacity semi-solid-state batteries for drones injects strong kinetic energy into this field, leading the industry to move towards a new high level of efficiency and intelligence.

I.UAV Semi-Solid Battery Technology: A Revolutionary Breakthrough in UAV Power System

Significant increase in energy density

UAV semi-solid battery technology represents an important evolutionary stage in the field of power batteries. Compared with traditional UAV liquid lithium batteries, UAV semi-solid batteries use solid electrolyte coating and gel electrolyte in-situ curing technology to achieve a significant increase in energy density. The energy density of semi-solid batteries from industry-leading companies has reached 350Wh/kg, far exceeding the performance of traditional UAV lithium batteries.

This increase in energy density translates directly into a significant improvement in UAV range. Actual tests conducted in the plateau region showed that the drone equipped with high-performance batteries was able to stably lift 210 kilograms of construction materials across 1.5 kilometers of treacherous terrain, successfully completing the lifting operation.

Low Temperature Performance Breakthrough

Horizon Power’s semi-solid UAV batteries utilize advanced ultra-low temperature electrolyte and composite diaphragm technology, enabling the batteries to work stably in ambient temperatures ranging from -40℃ to 60℃. This feature is especially important for lifting operations at high altitudes or in cold environments, ensuring the UAV’s reliable performance in extreme climatic conditions.

II. Practical Application Scenarios of Semi-Solid Batteries for Drones: The Efficiency Revolution of Drone Lift Transportation

Complex Terrain Transportation Solutions

When carrying out project construction in rugged mountainous terrain, the transportation of materials often faces great challenges. Traditional transportation methods require large-scale excavation of forest areas and construction of transportation roads, which not only increase construction costs but also cause greater damage to the ecological environment3.

Drone lifting technology effectively solves this challenge. In practical application, 5 drones can lift 100 tons of materials a day, compared with the traditional mule and horse transportation (a mule and horse can only transport 2 tons a day), the efficiency is significantly improved. A drone can carry 85 kilograms of cargo in one trip, and it takes only 30 seconds in the air to transport the material to its destination.

Agriculture and forestry applications

In the agricultural sector, drone lifting technology also shows great value.2025 In August, in Shifo Village, Caijia Town, Jiangjin City, two DJI T100 agricultural drones acted as “air porters”, steadily lifting freshly harvested rice grains from the fields to the village highway a hundred meters away.10 These drones have a maximum lifting capacity of 130 kilograms, which boosts the efficiency of traditional manpower transfer by 24 times.10 In the forestry transportation scenario, a drone can carry 85 kilograms in one trip, increasing efficiency significantly.11 In the forestry transportation scenario, a drone can carry 85 kilograms in one trip, increasing efficiency significantly.

In forestry transportation scenarios, drones are able to efficiently shuttle through complex terrains and accurately transfer wood, significantly reducing industrial operating costs and improving work efficiency.

II. Practical Application Scenarios of Semi-Solid Batteries for Drones: The Efficiency Revolution of Drone Lift Transportation

Complex Terrain Transportation Solutions

When carrying out project construction in rugged mountainous terrain, the transportation of materials often faces great challenges. Traditional transportation methods require large-scale excavation of forest areas and construction of transportation roads, which not only increase construction costs but also cause greater damage to the ecological environment.

Drone lifting technology effectively solves this challenge. In practical application, 5 drones can lift 100 tons of materials a day, compared with the traditional mule and horse transportation (a mule and horse can only transport 2 tons a day), the efficiency is significantly improved. A drone can carry 85 kilograms of cargo in one trip, and it takes only 30 seconds in the air to transport the material to its destination.

Agriculture and forestry applications

In the agricultural field, drone lifting technology also shows great value. in August 2025, in the village of Shifo, Caijia Town, Jiangjin City, two DJI T100 agricultural drones acted as “air porters” and steadily lifted the freshly harvested rice grains from the fields to the village highway, which is 100 meters away.10 These drones have a maximum lifting capacity of 130 kilograms, which boosts the traditional manpower transfer efficiency by 24 times.

In forestry transportation scenarios, drones are able to efficiently shuttle through complex terrains and accurately transfer wood, significantly reducing industrial operating costs and improving work efficiency.

III. Safety Performance Advantage: Providing Reliable Guarantees for Critical Missions

Intrinsically Safe Design

MEGAMAN® semi-solid batteries reduce the risk of leakage and combustion from the root by reducing the use of liquid electrolytes.1 In semi-solid batteries, the solid electrolyte coating strengthens the ion transport path and improves the high rate discharge capability, while the in-situ curing of the gel electrolyte dramatically reduces the risk of leakage and enhances the resistance to thermal runaway.

This safety design is particularly important in special environments such as strong winds in high mountains and humid ravines, ensuring stable power supply and safe operation of UAV lifting operations.

Intelligent Battery Management System

Modern UAV batteries are equipped with advanced battery management systems (BMS) that can monitor parameters such as voltage, temperature, and cycle count in real time. These systems support battery state estimation based on voltage, current, internal resistance, temperature and Kalman filter algorithms, with high SOC calculation accuracy.

Meanwhile, the intelligent BMS is also equipped with an adaptive temperature-controlled charging algorithm that heats up in a low-temperature environment and dynamically adjusts the charging current to ensure efficient and safe charging.5 When the power level falls below 15%, the system will be forced to shut down, effectively avoiding the risk of crashing due to “greed for flying”.

IV. Analysis of economic benefits: Reduction of overall operating costs

Maintenance cost optimization

The modular design of UAV semi-solid batteries significantly reduces maintenance costs. The latest patented technology shows that individual damaged semi-solid electrolytic packs can be replaced individually without the need to replace the entire battery, significantly reducing maintenance costs and avoiding waste of resources. This kind of maintenance is easy to operate and does not require complex tools and specialized skills, saving maintenance time.

Operational Efficiency Improvement

The high energy density of the Horizon Power UAV’s semi-solid battery enables the UAV to extend the duration of a single operation and reduce the number of return flights for recharging. In applications such as highway bridge inspections, material transportation tasks that used to take 30 minutes to complete now take only 3 minutes with the drone.

This efficiency improvement not only reduces the time cost, but also reduces manpower demand, realizing “zero artificial climbing” and solving the safety problem of material transportation in high-risk areas.

V. Future Outlook of the Industry: Development Trends of Semi-Solid Battery Technology for UAVs

Iteration of semi-solid battery technology for drones accelerates

Semi-solid battery technology for drones is still developing rapidly. Industry leaders are developing battery technology with an energy density of more than 400Wh/kg, which is expected to bring drone range into the 2-hour era. Meanwhile, fast-charging technology is also progressing, with batteries supporting 5C fast charging capable of charging 80% in 12 minutes, significantly shortening waiting time on the ground.

Application Scenario Expansion

With the advancement of battery technology, the application scenarios of UAV lifting are expanding. From the initial electric power inspection and agricultural spraying, it has developed into many fields such as logistics and transportation, building construction, and emergency rescue.

In emergency rescue scenarios, UAVs empowered by Meiyu batteries can respond quickly to natural disasters and, with long endurance and high safety, continuously deliver rescue supplies to remote or inaccessible areas.

VI. Five reasons to choose Horizon Power’s semi-solid batteries for UAVs

- Excellent Energy Density: High energy density of 350Wh/kg provides longer range and improves operational efficiency

- Wide Temperature Range Performance: Stable operation in ambient temperatures ranging from -40℃ to 60℃, adapting to extreme climatic conditions

- Safety Guarantee: Semi-solid structure of the drone reduces the use of liquid electrolyte, lowering the risk of leakage and combustion

- Intelligent Management: Real-time monitoring of the battery status by advanced BMS system ensures safe operation Economic and Efficient: Modular design reduces maintenance costs, and high operational efficiency reduces operational expenses Ensure safe operation

- Economical and efficient: modularized design reduces maintenance costs and efficient operation reduces operating expenses