How to Customize 18650 Lithium Battery Packs

From Precise Parameter Matching to International Safety Certifications: A Comprehensive Analysis of Key Technical Points in 18650 Battery Pack Customization

As a lithium battery technology engineer, how should one customize 18650 lithium battery packs? I believe customizing 18650 lithium battery packs is a systematic engineering endeavor requiring precision design and deep understanding of application scenarios. Successful battery pack customization demands not only selecting suitable cells but also comprehensive consideration of the battery management system, structural design, and safety certifications.

The 18650 lithium battery, with its standardized specifications and mature technology, has become an ideal choice for numerous applications. However, each step in the customization process must be handled with care to ensure the final product achieves an optimal balance of performance, safety, and longevity.

I. Application Scenario Analysis for 18650 Lithium Battery Packs: Identifying Core Requirements

The first step in customizing 18650 lithium battery packs involves thoroughly analyzing the specific demands of the application scenario. Different applications exhibit significant variations in battery performance requirements:

Medical devices demand exceptionally high reliability and stability to ensure continuous, uninterrupted operation. Battery packs typically require redundant designs and multiple protection mechanisms.

Power tools prioritize high-rate discharge capability, demanding batteries deliver substantial currents in short bursts without excessive heating or voltage sag.

Drone lithium battery applications are highly sensitive to energy density and weight, demanding maximum energy output within limited space and weight constraints.

Energy storage systems prioritize cycle life and cost-effectiveness, typically requiring batteries to maintain over 80% capacity after thousands of cycles.

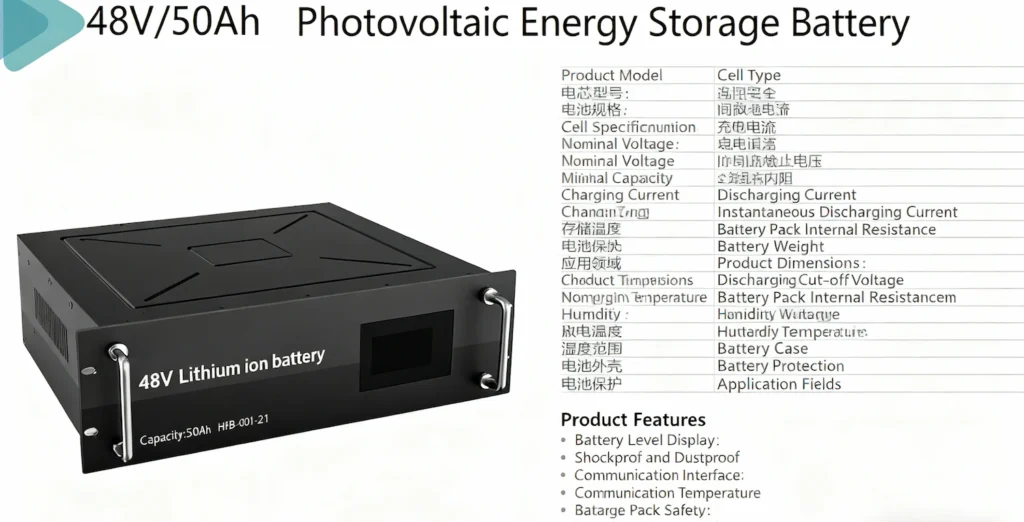

After defining the application scenario, key parameters such as voltage requirements, capacity specifications, dimensional constraints, operating temperature range, and expected lifespan must be clearly established.

II. Selection and Matching of 18650 Lithium Battery Cells: Performance Fundamentals

Selecting high-quality cells is the cornerstone of battery pack performance. 18650 cells typically range in capacity from 1300mAh to 2800mAh, though higher-capacity models are also available.

Consistency among 18650 lithium battery cells is critical to battery pack performance. Ensure parallel cells have voltage, internal resistance, and capacity as closely matched as possible to prevent imbalance escalation during cycling.

Select cells based on application requirements:

- – Ternary Materials (NMC): Offer high energy density, suitable for space-constrained applications

- – Lithium Iron Phosphate (LFP): Provide extended cycle life and enhanced safety, ideal for industrial applications

- – High-Temperature Cells: Suitable for scenarios with elevated ambient temperatures

III. Battery Management System Design: Safety Core

The Battery Management System (BMS) serves as the “brain” of the battery pack, responsible for monitoring and protecting the batteries. A complete BMS should incorporate the following protective functions:

Overcharge Protection: Cuts off the charging circuit when the voltage of each battery cell reaches 4.3±0.025V

Over-Discharge Protection: Halts discharge when voltage drops to 2.8±0.05V

Overcurrent Protection: Triggers protection when current exceeds a set value (e.g., 3-7A)

Short-Circuit Protection: Cuts off the circuit within 5-48 microseconds upon detecting a short circuit

Temperature Protection: Ceases operation when temperature exceeds the operating range (e.g., -20°C to 60°C)

Advanced BMS should also feature state-of-charge measurement, balancing functions, and communication interfaces to exchange information with host devices.

IV. Structural Design and Thermal Management: Ensuring Reliability

The mechanical structure design of the battery pack directly impacts its reliability and safety. Key considerations during design include:

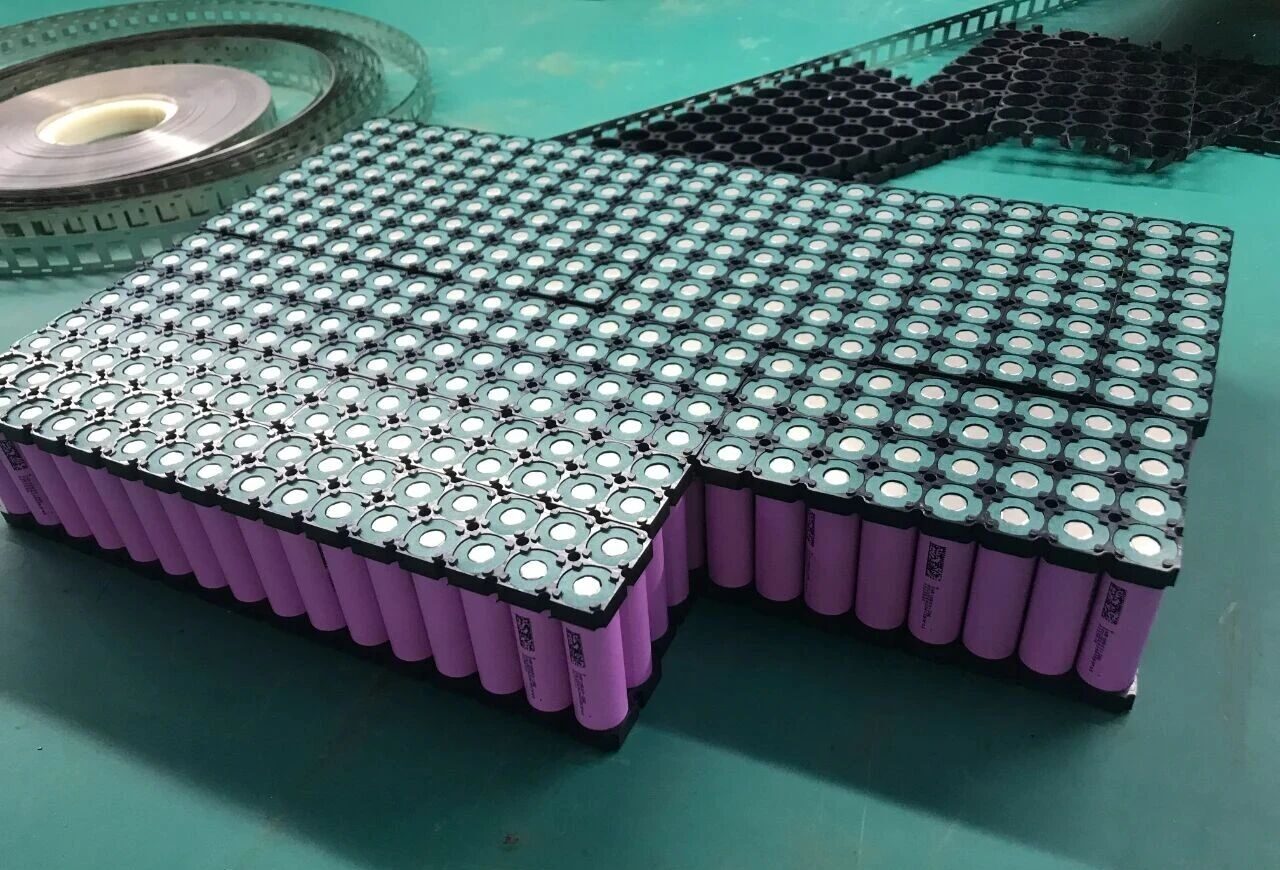

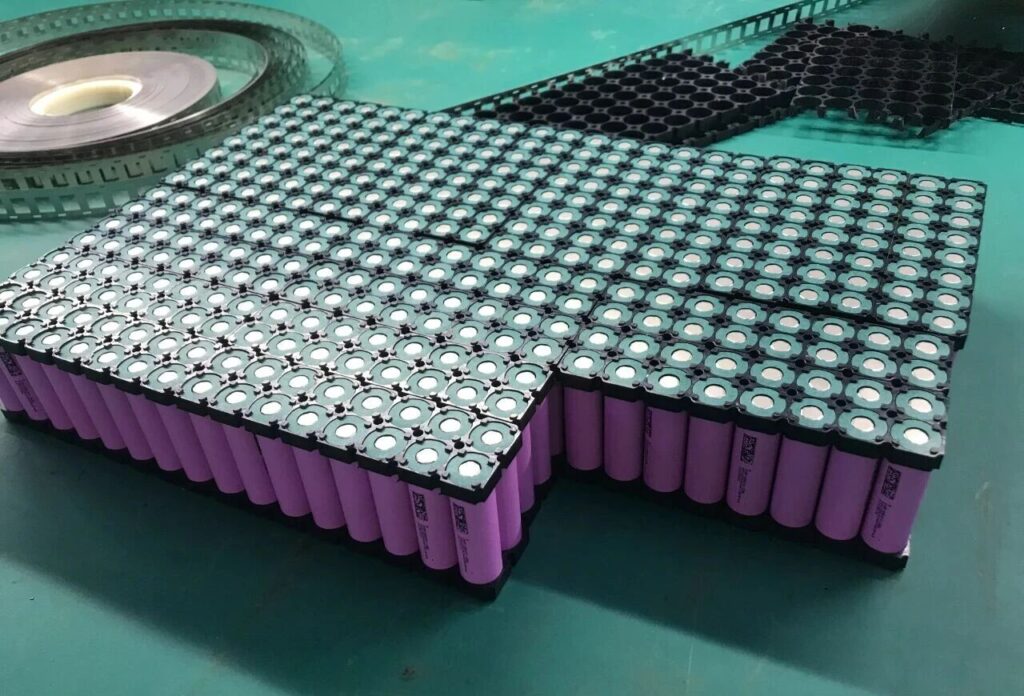

Connection Method: Cells should be connected in a parallel-then-series configuration. Parallel connections require consistent or nearly identical internal resistance among cells. Welding with nickel strips and spot welders is recommended to ensure secure and reliable connections.

Insulation Treatment: Apply self-adhesive O-ring insulation sheets around each cell’s positive terminal. Insert insulation sheets between the equalization board and cells to prevent short circuits.

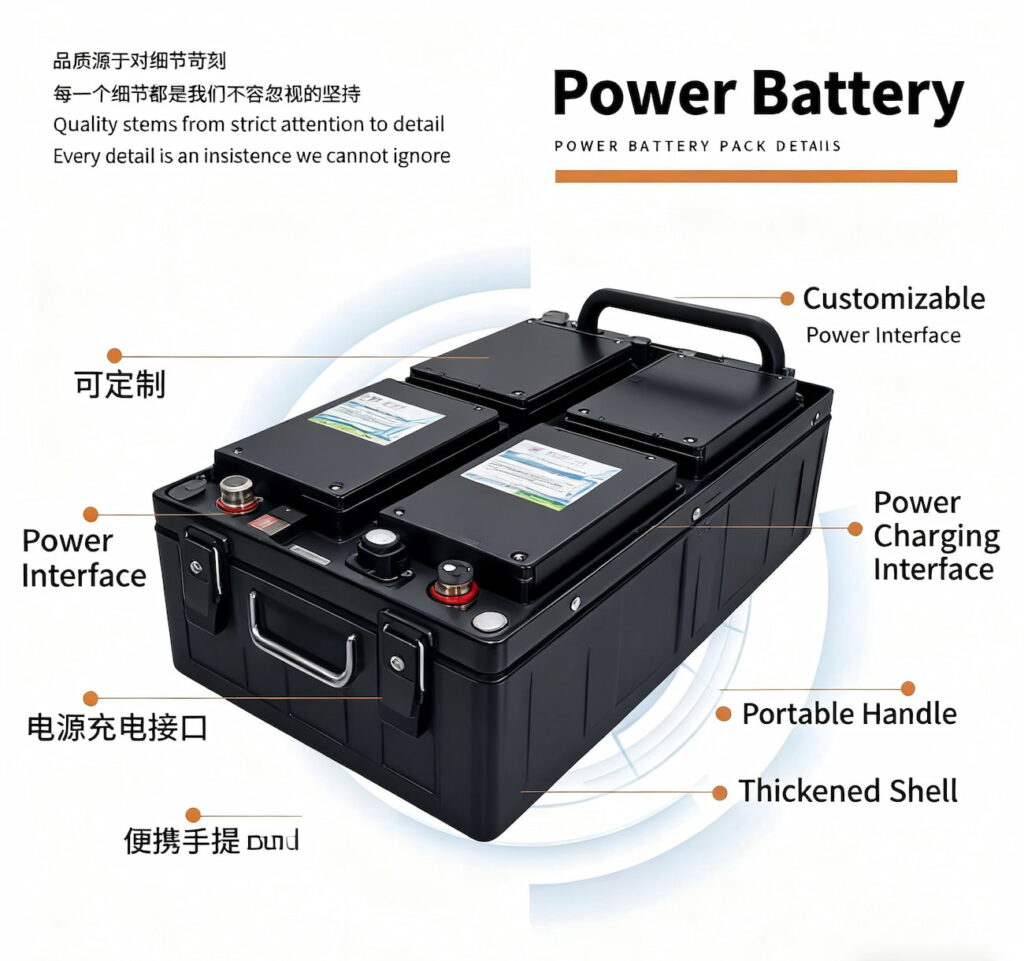

Housing Design: Select appropriate housing materials and protection ratings (e.g., IP64) based on the application environment to prevent dust and moisture ingress.

Thermal Management: Large-sized battery packs require effective heat dissipation pathways to prevent overheating during charging and discharging. For high-power applications, consider adding thermal interface materials or heat sinks.

V. Certification and Compliance: Market Access

Depending on the target market and application, battery packs must undergo relevant safety certifications and transportation testing:

UL Certification: UL1642 is the safety standard for individual lithium-ion cells, serving as a critical certification for entering the North American market.

UN38.3: Mandatory testing to ensure battery transport safety, including altitude simulation, thermal testing, vibration, shock, external short-circuit, impact/crushing, overcharge, and forced discharge.

CE Certification: Essential for entering the European market

Other Certifications: Depending on the application, specific certifications like IEC 62133 (portable devices) or IEC 62619 (industrial batteries) may also be required

Special Note: Certain platforms (e.g., Amazon) impose strict restrictions on 18650 batteries, even prohibiting the sale of products containing them. Understand target market regulatory requirements before customization.

VI. Production Processes and Quality Control

Process consistency during mass production directly impacts battery pack performance and safety:

- Welding Process: Automated spot welding equipment ensures consistent resistance at each connection point

- Cleaning Procedure: Pressing machines are cleaned with alcohol every 2 hours to maintain a clean production environment

- Vacuum Drying: Coated positive and negative electrodes are dried in vacuum ovens at a vacuum level of -0.09 MPa

- Full Inspection Process: Each battery pack undergoes voltage, internal resistance, and functional testing to ensure compliance with specifications.

A comprehensive traceability system is established to record the cell batch, production date, and test data for each battery pack, facilitating subsequent quality tracking.

VII. Customized Services and Technical Support

Professional battery suppliers should offer comprehensive customized services:

Parameter Customization: Lithium battery packs can be tailored to your specifications for voltage, capacity, and protection parameters.

Flexible Dimensions: Battery pack sizes optimized for device space constraints

Interface Compatibility: Multiple connector and interface options ensuring seamless integration with host equipment

Technical Support: Full-cycle assistance from concept design to mass production, including on-demand development, rapid response, and long-term maintenance

Selecting an experienced supplier is crucial, as they can anticipate potential issues and prevent them during the design phase.

Customizing 18650 lithium battery packs is a multidisciplinary engineering task that requires balancing multiple factors including performance, safety, cost, and reliability.

Success hinges on thoroughly understanding application requirements, selecting appropriate cells and BMS, optimizing mechanical and thermal designs, and ensuring compliance with all relevant certification standards. Partnering with experienced battery suppliers can significantly reduce development risks and shorten time-to-market.

As battery technology continues to advance, 18650 battery packs are also evolving. Higher energy density cells, smarter BMS, and more advanced manufacturing processes are driving lithium battery customization services to new heights.