In-Depth Analysis of Capacity Plunge in Ternary Lithium Batteries: Mechanism Research and Failure Analysis

As a website dedicated to industrial-grade lithium battery technology research, we remain committed to unraveling core battery issues. Through systematic experimentation, this paper reveals the causes behind the capacity plunge phenomenon in ternary lithium batteries, providing technical references and solutions for the industry.

I. Experimental Design and Methods

1.1 Battery Samples and Test Conditions

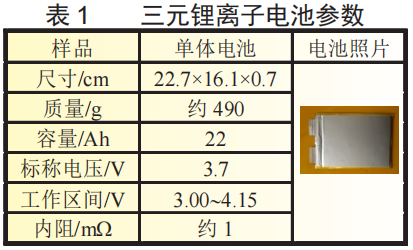

A square pouch-type ternary lithium battery (NCM111/graphite system, nominal capacity 22Ah) from an automotive manufacturer was selected for study. Using a Neware charge-discharge testing system, accelerated aging cycles were conducted within the 4.15V–3.00V voltage range to compare performance evolution under different temperatures (25°C/45°C) and rates (1C/2C).

1.2 Multi-dimensional Analysis Methods

Gas Chromatography (GC): Analyzed gas evolution components;

Button Cell Assembly: Evaluated residual capacity of cathode and anode materials;

XRD and SEM: Observed changes in material crystal structure and morphology;

ICP-OES: Detected leached metal ion content.

II. Key Findings and Mechanism Analysis

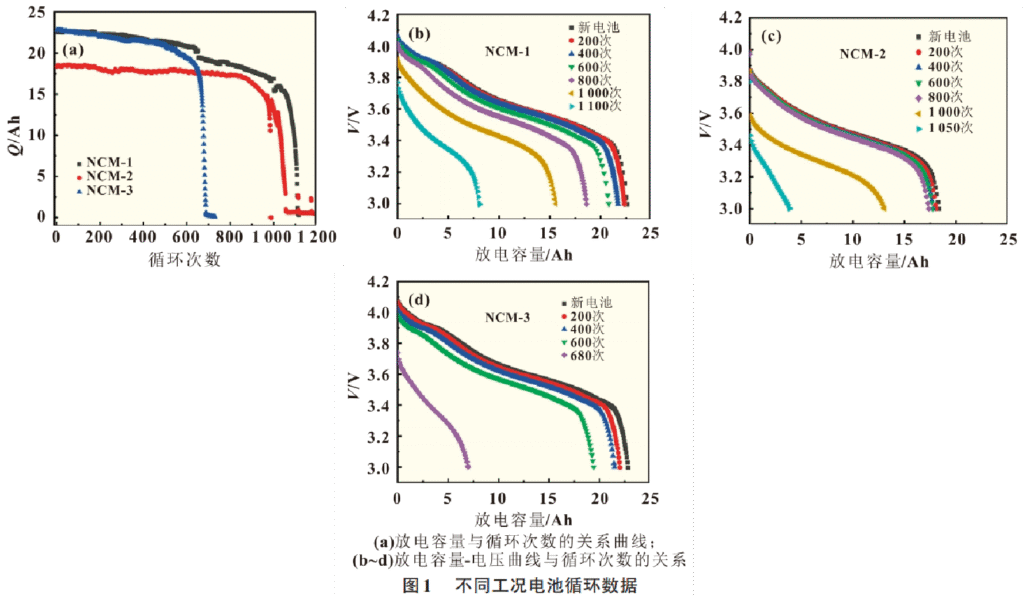

2.1 Cycling Performance and Capacity Cliff Characteristics

High-Temperature High-Rate Accelerated Failure: At 45°C + 2C, the battery exhibited a steep capacity decline after 600 cycles, with a single-cycle capacity loss reaching 155.5 mAh.

Surge in Internal Resistance and Voltage Platform Collapse: During the plunge phase, battery internal resistance significantly increased, and discharge curves exhibited abrupt voltage drops, indicating deteriorated interfacial impedance.

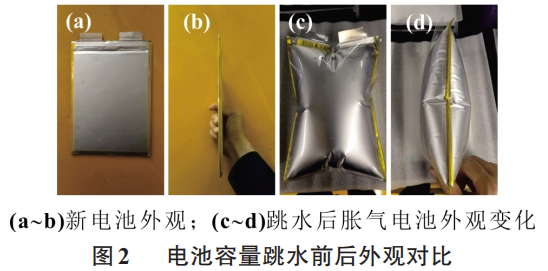

Gas Swelling and Structural Deformation: Post-plunge, battery thickness increased by 65.5%. Gas evolution primarily consisted of H₂, CO, and CH₄, originating from electrolyte decomposition and SEI side reactions.

2.2 Cathode Failure: The Dominant Factor in Capacity Plunge

Discharge testing: The cathode capacity loss rate in plunging batteries reached 67.96%, far exceeding that of the anode (7.24%), indicating cathode degradation as the primary cause of performance decline.

Crystal Structure Stability: XRD revealed that the layered structure of the cathode remained intact, but the increased R factor indicated a decrease in material order.

Particle Fracturing and Metal Leaching: SEM observed cracking of NCM secondary particles and significant leaching of Mn into the electrolyte, accelerating electrolyte consumption and interfacial side reactions.

2.3 Synergistic Degradation of Anode and Electrolyte

Graphite Pulverization and SEI Thickening: The anode active material in the plunge-type battery detached with visible surface cracks, leading to reduced packing density and thickened electrode sheets.

Electrolyte Depletion: Post-disassembly electrode sheets exhibited a dried-out state, confirming complete electrolyte consumption during side reactions.

III. Conclusions and Industry Implications

- Operating Condition Sensitivity: High temperatures and high-rate cycling significantly accelerate capacity plummeting in ternary lithium batteries.

- Cathode-Dominated Failure: Core drivers include NCM particle fracture, transition metal dissolution (particularly manganese), and electrolyte depletion.

- Gas Generation Risk: Post-plummeting gas expansion may cause structural deformation and short-circuit hazards, necessitating rigorous battery safety management.

Currently, research into the mechanisms behind capacity plummeting in ternary lithium batteries requires further exploration. As the new energy industry demands higher energy density batteries, breakthroughs in material structural stability and interfacial control technologies will become industry priorities. This platform will continue sharing cutting-edge battery technologies to drive dual upgrades in safety and performance.