K-value of lithium battery: a key indicator of self-discharge performance

Core Technical Parameters for Accurately Assessing Battery Quality and Consistency

In the field of lithium battery technology, K-value, as a key performance indicator, is not as well known as capacity and voltage, but plays a crucial role in assessing the quality, consistency and safety of batteries. In this paper, we will analyze the core technical points of K-value of Li-ion battery from the engineering point of view.

I. The essence of lithium battery K value: quantify the self-discharge rate of lithium batteries

Lithium battery K value refers to the battery voltage drop per unit time, usually in mV/d (millivolt/day) or mV/h (millivolt/hour) as a unit. It is the core indicator of the self-discharge rate of lithium batteries, reflecting the ability of the battery to maintain charge in the resting state.

From the electrochemical point of view, self-discharge is an inherent characteristic of lithium batteries, even when not connected to any external load, the battery internal chemical reaction will spontaneously lead to the gradual loss of power. k value is the quantitative expression of this rate of power loss.

The K value of high quality Li-ion battery is usually less than 2mV/d or 0.08mV/h, which indicates that it has very low self-discharge rate and can maintain charge and voltage stability for a long time.

II.The engineering significance of lithium battery K-value: the eyes of the fire for quality control

Identifying cells with micro-short circuits

The K-value test of lithium battery can effectively identify cells with poor performance due to internal micro-short circuits. These micro-shorts may originate from tiny particles, metal residues on the pole piece, defects on the diaphragm, or dust introduced during the assembly process. These small defects cannot be detected by conventional capacity and voltage tests, but are potential safety hazards.

Predicting long-term storage performance

Lithium batteries with too large a K-value have too rapid a voltage drop during storage, which can lead to deterioration in the voltage consistency of the battery pack. This is especially important for battery applications that require long-term storage before use, such as backup power systems and seasonal use equipment.

Aids in screening for other performance issues

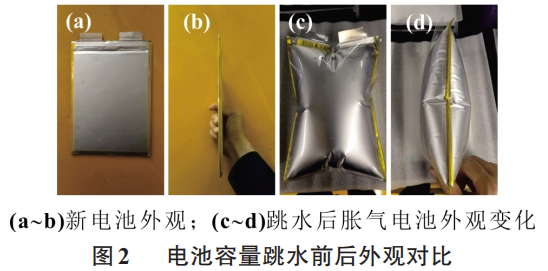

Abnormal K-values in Li-ion batteries can also indicate other performance issues, such as corrosion gassing (possibly due to poor aluminum-plastic film encapsulation) or poor cycling performance (possibly due to accelerated side reactions from internal micro-shorts). Through Li-ion battery K-value testing, these “problem cells” can be identified and eliminated in a timely manner, ensuring the overall quality and performance of the battery pack.

III.Calculation method and measurement requirements of lithium battery K-value

Calculation formula

The calculation of K value of lithium battery is based on the measurement of open circuit voltage at two time points:

K = (OCV1 – OCV2) / (t2 – t1)

where:

- OCV1: open-circuit voltage measured at time t1

- OCV2: open-circuit voltage measured at time t2

- t2 – t1: time interval between two measurements

Measurement environmental requirements

Lithium battery K-value measurement is extremely sensitive to environmental conditions and requires strict control of temperature, humidity and other factors. High temperature will accelerate the internal chemical reaction of the battery, leading to an increase in self-discharge; high humidity may lead to water intrusion inside the battery, triggering adverse reactions. Therefore, K-value testing is usually performed in a constant temperature and humidity environment with high-precision measurement equipment.

The industry usually uses high-temperature storage (e.g., 45°C or higher) to conduct K-value testing for two purposes: first, to pre-screen out corrosive and gas-expanded cells by accelerating at high temperatures; and second, to stabilize the voltage drop rate of the cells and improve the consistency of the test results5.

IV. Analysis of key factors affecting K-value

Influence of material system

Different positive and negative electrode materials have a significant effect on K value. Studies show that the self-discharge rate of ternary material batteries is usually higher than that of lithium cobalt acid batteries. The type of electrolyte, thickness and type of diaphragm also affect the K-value, because they directly affect the ion transport and side reaction rate inside the battery.

Influence of storage conditions

Storage time and storage conditions are critical to K-value measurement. An increase in storage time increases the absolute value of the voltage drop and improves measurement accuracy, but too long a storage time may disrupt the capacity balance between the positive and negative electrodes, leading to irreversible capacity loss.

Increases in storage temperature and humidity significantly increase the degree of self-discharge.1 For every 10°C increase in temperature, the self-discharge rate of the battery may increase by a factor of 2-3, which has a direct impact on the K-value measurement results.

Other influencing factors

Self-dissipation of the battery protection plate1 and the initial voltage of the test1 also affect the K-value measurement results. A high initial voltage usually leads to an increase in the self-discharge rate1 , so it is necessary to ensure the consistency of the initial voltage during the test.

V. Engineering practice of lithium battery K-value test

Test Flow

The standard K-value test process for lithium batteries includes:

- 1. Do not test the voltage immediately after the cell divides, but store it for a few days first

- 2. Measure OCV at a specific time point (t1)

- 3. Continue to store for a period of time and then measure OCV at the time point (t2)

- 4. Calculate K value according to the formula

Test Equipment

High-precision voltage measurement equipment is the key to ensuring the accuracy of K-value testing. Precision digital multimeters such as Keithley’s DMM7510 are commonly used in the industry for open-circuit voltage measurements. With a voltage measurement accuracy of up to 14 ppm and a sampling speed of 1M sample points/second, the device is able to meet the demanding requirements of K-value testing.

VI. Correlation between K-value and battery performance of lithium batteries

Capacity retention

Lithium batteries with large K-value usually have poor capacity retention. After long-term shelving, the irreversible capacity loss of these batteries is significantly high (e.g. three months irreversible capacity loss of 5%, while normal batteries need a year to reach this value).

Multiplier Performance and Cycle Life

Lithium batteries with abnormal K values tend to have lower multiplicative performance (0.5C/0.2C, 1C/0.2C capacity retention) and poorer cycling performance, and are prone to lithium precipitation and other phenomena after cycling. These problems can significantly shorten the actual service life of the battery.

VII. Industrial Applications and Future Prospects

Key Parameters for Battery Matching

The K-value is one of the most important screening criteria for batteries that need to be assembled.5 Only batteries with similar K-values can be assembled to ensure that the battery packs maintain good consistency during long-term use.

Quality Control Standard

K-value testing has become a mandatory test item for lithium battery manufacturers before shipment.5 By comprehensively testing and screening the K-value, companies can ensure the consistency of the quality of the batteries leaving the factory and reduce the risk of after-sales.

Technology Development Trend

With the advancement of technology, K-value testing is developing in the direction of higher precision and shorter testing time.5 In July 2025, Chongqing Ganfeng Power Technology Co., Ltd. applied for a patent on “Method of Formulating K-value Standard for Power Battery”, which realizes the accurate formulation of K-value standard without the need to produce samples in the pre-production stage of the project, and shortens the development cycle by more than 50%9 through integrating the technologies of dynamic balanced current regulation, user behavioral modeling, and aging compensation. The development cycle was shortened by more than 50%.

VIII. Engineering solutions to reduce the K-value of lithium batteries

Material optimization

Selection of low self-discharge positive and negative electrode materials, optimization of electrolyte formulation (improve conductivity, reduce impurities), use of high-performance diaphragm (improve pore uniformity and mechanical strength) can effectively reduce K value.

Process control

Strictly control the temperature, humidity and cleanliness of the production environment to avoid the introduction of impurities; Li-ion batteries optimize the process parameters of electrode coating, rolling, winding, liquid injection and encapsulation to ensure the consistency of the internal structure of Li-ion battery cells.

Quality Inspection

Establish a perfect quality inspection system and adopt high-precision inspection equipment (such as X-ray flaw detector and high-precision voltage testing instrument) to discover and reject defective cells in time to ensure the consistency of K value of the factory products.