Latest Chinese Drone Semi-Solid State Battery Transformation

I. Industry pain points: the three major dead ends of traditional lithium batteries and China’s solid-state battery breakthrough logic

Behind the explosive growth of the drone industry, battery is always the biggest short board. The bottleneck of traditional lithium batteries has become an industry consensus:

🔋 Energy density trap: liquid system long-term stuck in 250Wh/kg ceiling, DJI M300 and other industrial machine range is difficult to exceed 40 minutes, load and airtime is forced to choose between two;

🔥 Thermal runaway risk: electrolyte leakage triggered 18% of the drone accidents (IASA 2023), puncture, extrusion that is, the fire;

❄️ low-temperature paralysis: -20 ° C environmental discharge efficiency plummeted by 40%, and operation in alpine areas is nearly paralyzed.

Chinese solid-state battery companies give answers:

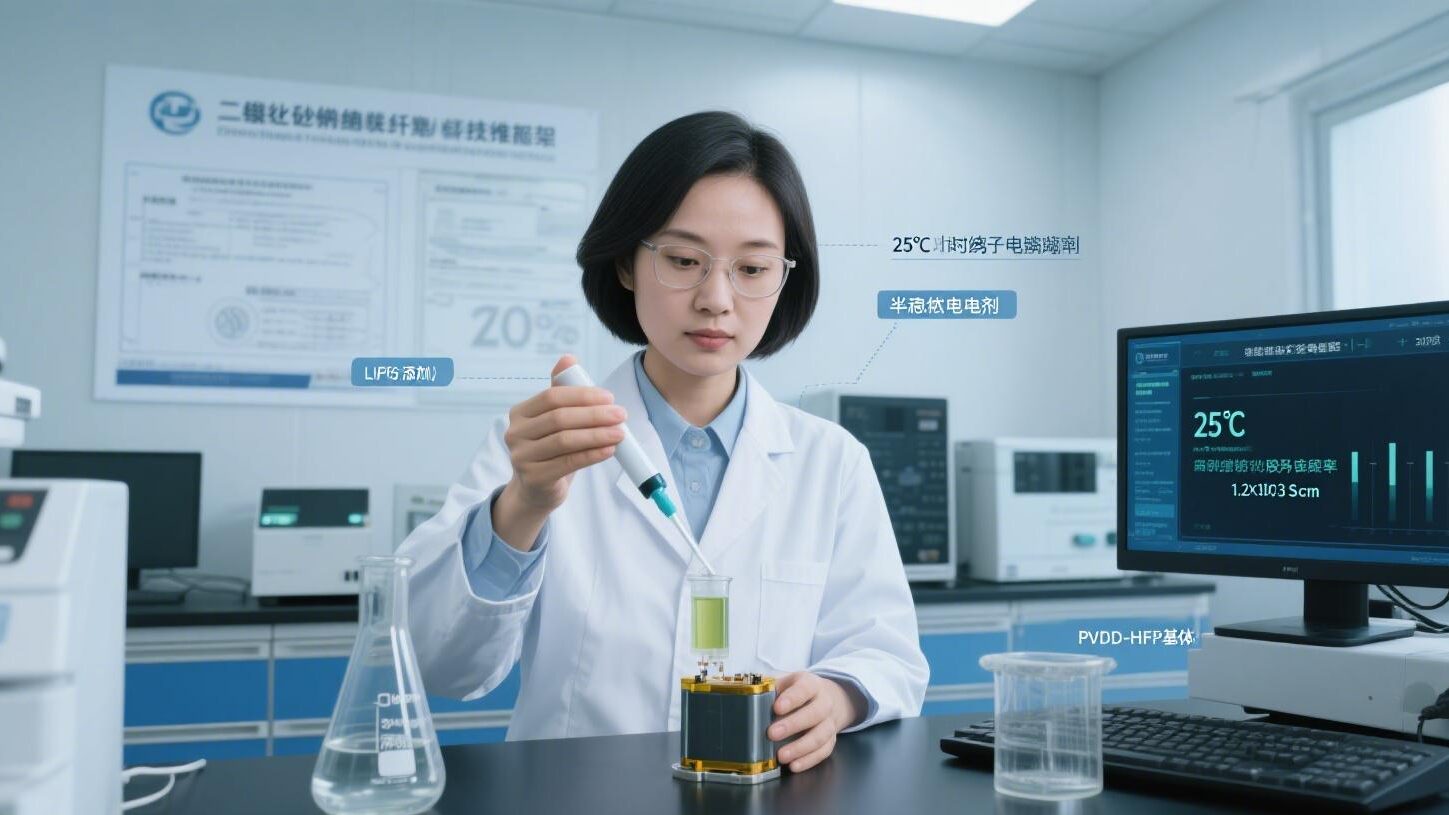

UAV semi-solid state technology with gel electrolyte as the core breakthrough – polymer network to lock the liquid components, ionic conductivity breakthrough 10-⁴ S/cm, while lithium dendrite inhibition efficiency increased by 300%. The measured data of VNN Technology shows that the cycle life jumps from 800 times to 1500 times +, and the thermal runaway trigger temperature rises from 180℃ to 300℃, completely reconstructing the safety boundary.

II. Performance Revolution: China’s Semi-Solid State Battery’s Hardcore Data List

✅ Energy density at the top

| manufacturer | Product generation | energy density | application scenarios |

|---|---|---|---|

| Feng Technology | second generation | 330Wh/kg | eVTOL/heavy-duty logistics |

| Grape | TARBG35 | 350Wh/kg | industrial drone |

| Sunwoda | fourth-generation prototype | 500Wh/kg | aircraft |

The actual test performance crushed:

10kg class logistics machine airtime from 30 minutes → 65 minutes (117% increase), load increase of 25%;

Extreme cold performance: -30 ℃ discharge retention rate of 85% (traditional batteries ≤ 60%), Heilongjiang winter fire drones take off and land as usual.

🛡️ Safety Performance Downgrade Strike

Pinprick test: voltage retention rate >90% (second generation of Vonergy);

Aviation-grade certification: passed FAA RTCA DO-311, UL1642, thermal runaway suppression efficiency increased by 300%6;

Military-grade vibration-resistant: 10-meter drop + 5G vibration (MIL-STD-810G).

💰 TCO (Total Cost of Ownership) Reconfiguration

| cost item | Traditional lithium batteries | Semi-solid state battery | degree of reduction |

|---|---|---|---|

| cycle life | 800times | 1500times+ | +87% |

| Number of replacements in 5 years | 6times | 3times | -50% |

| Fast charging efficiency | 0.5C | 1C~5C | +200% |

Conclusion: 20% higher initial cost → 45% lower 5-year combined cost.

III. China’s Technology Path: From Material Innovation to Aerospace-Grade Manufacturing

🧪 Material-level breakthroughs

Electrolyte: oxide/polymer composite system (Vonergy Technology) → Ion mobility increased by 3 times;

Negative electrode: silicon-carbon composite material (Grape) → Gram capacity 1300mAh/g, first efficiency ≥92%;

Diaphragm: ceramic coating (Al₂O₃) → Thermal shrinkage <1% (traditional 5-10%).

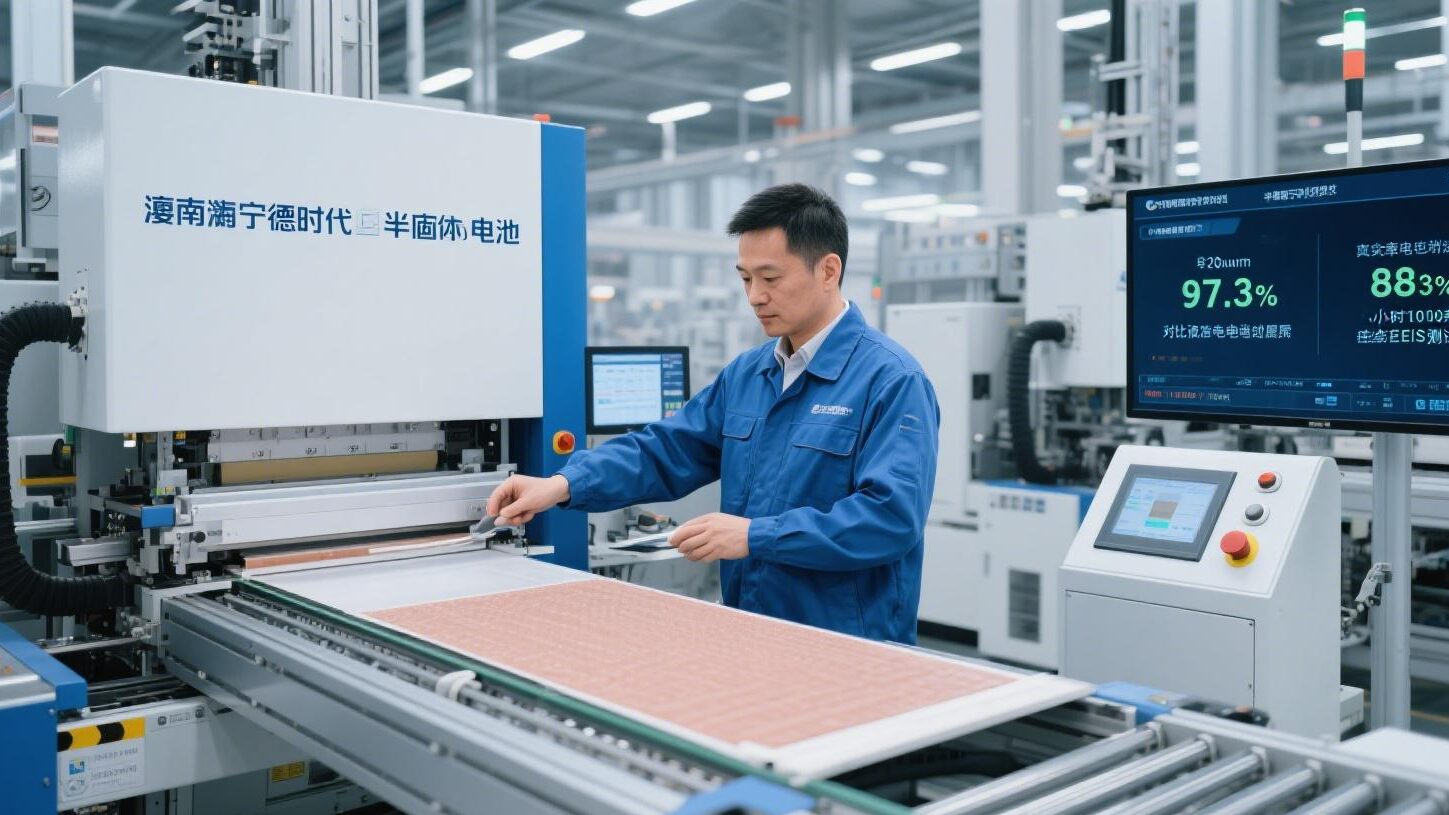

🏭 mass production killer application

In-situ curing process: interfacial impedance <50mΩ/cm² (Synventive Patent);

Intelligent production line: laser welding + AI quality inspection → 99% yield rate (Grape Jiangsu base);

Monthly production capacity: 5GWh (end of 2025) of eVTOL dedicated line of Vonergy Technology.

IV. Scenario validation: China’s program is rewriting the rules of the global low-altitude economy

🚚 Logistics

Case: Time’s Technology E20 tilt-rotor aircraft (Vulnerable Battery) → 220km range + 5kg load, signing a contract with UAE for USD 1 billion;

Effectiveness: 70% increase in distribution efficiency, daily revenue of USD 12,000 for a single aircraft.

🌾 Agricultural plant protection

Data: equipped with Grappler TARBG30 battery → single operation of 200 acres, daily workload tripled;

Cost: 3 years free of electricity replacement, cost per acre pressed down by 60%.

🚒 Emergency rescue

Actual combat: plateau fire-fighting UAV (-30℃ start) continuous operation for 2 hours, extinguishing 10 forest fires.

V. Trends Ahead: China’s Next Battlefield for Solid State Batteries

🚀 Technology evolution roadmap

2025->Semi-solid 350Wh/kg –> Vonergy/Greep mass production –> 2026->|full solid 400Wh/kg –> Hinwanda lab validation –> 2027->Non-negative technology 600Wh/kg –> Sulfide electrolyte pilot test

🌍 Global Competitive Landscape

China leads the way: Vonergy/Qingtao/TaiLan occupy 67% of aviation battery patents6;

International benchmarking: Toyota’s all-solid-state mass production jumps to 2030, U.S. Department of Energy smashes $2 billion to make up for it.

Wang Mingyuan (China Battery Industry Association):

“Semi-solid-state batteries have crossed the lab stage and will devour 40% of the high-end UAV market in the next 5 years. China’s technological discourse on solid-state batteries is the right to control the airspace of the low-altitude economy.”