Lithium-ion Battery Pack Technology

As the integrated core of energy storage systems, lithium-ion battery packs transform individual cells into safe and reliable energy solutions through precision structural design, thermal management, and intelligent control systems.

As lithium battery engineers, we recognize that lithium-ion battery packs are far more than simple enclosures—they represent complex systems integrating electrochemistry, thermodynamics, electronic control, and mechanical engineering. By assembling dozens or even hundreds of individual cells into complete energy solutions, they directly influence the performance, safety, and lifespan of energy storage systems.

In modern energy storage systems, the lithium-ion battery pack serves as the “power heart”—not only efficiently storing and releasing electrical energy but also ensuring safe, stable operation under diverse environmental conditions. From large-scale wind farm storage to commercial and industrial backup power, and increasingly popular residential energy storage devices, all rely on battery pack technology.

I. Core Components of Lithium-Ion Battery PACK Systems

A lithium-ion battery PACK comprises five critical subsystems, each performing irreplaceable functions:

Battery Module: Energy Storage Core

Battery modules consist of multiple individual cells arranged in a scientifically designed series-parallel configuration, serving as the PACK system’s energy source. Typically utilizing lithium iron phosphate (LFP) or ternary (NMC) cells, series connections increase voltage while parallel connections boost capacity. Cell consistency is critical to system performance, with capacity, internal resistance, and voltage variations controlled within 2%.

Battery Management System (BMS): Intelligent Control Hub

The BMS serves as the “brain” of the PACK, continuously monitoring battery status and ensuring safe operation. Key functions include:

- State Monitoring: Collects cell voltage, current, and temperature to calculate SOC (State of Charge) and SOH (State of Health)

- Charge/Discharge Management: Prevents overcharging, over-discharging, and overcurrent, ensuring operations remain within safe limits

- Balancing Control: Adjusts cell states via active or passive balancing technologies to prevent lifespan degradation caused by consistency variations

- Data Communication: Uploads monitoring data to cloud platforms or energy storage system control centers, enabling remote monitoring and maintenance

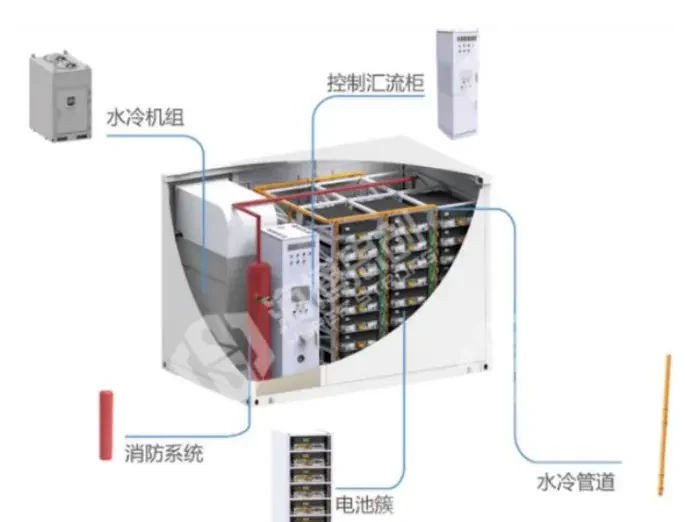

Thermal Management System: Temperature Regulation Assurance

Thermal Management System maintains cells within optimal operating temperatures (typically 15-35°C), ensuring temperature differential ≤5°C. Two primary technical approaches exist:

- Liquid Cooling System: Absorbs heat through coolant circulation, offering high heat dissipation efficiency and precise temperature control, suitable for high-power energy storage stations

- Air Cooling System: Utilizes airflow to dissipate heat, featuring simple structure and low cost, suitable for small-to-medium power applications

Research indicates that phase-change material cooling delivers the most stable performance during multiple charge-discharge cycles, maintaining peak cell temperatures below 50°C with surface temperature differentials under 3°C.

Electrical System: Energy Transmission Network

The electrical system manages power delivery and signal transmission, comprising:

- High-voltage wiring harness: Conveys high-voltage energy stored in battery modules to external loads

- Low-voltage wiring harness: Transmits BMS control signals and cell status data

- Connecting Busbars: Conductive bridges between cells and modules

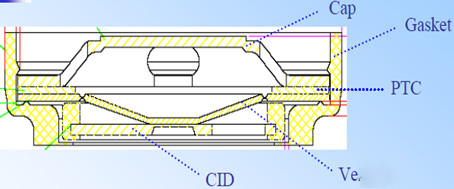

- Protective Components: Fuses, relays, and other electrical protection devices

Structural Enclosures: Physical protective housings

The enclosure serves as the external protective structure, providing mechanical support and environmental protection, typically meeting IP65 protection rating or higher. Modern enclosure designs also integrate fire-resistant materials to further enhance safety performance, resisting external impacts, vibrations, and environmental factors.

II. Lithium Battery Pack Manufacturing Process Flow

Lithium battery pack manufacturing involves six critical stages, each directly impacting the final product’s performance:

Cell Manufacturing and Testing

Cell manufacturing forms the foundation, encompassing processes such as positive and negative electrode material preparation, coating, calendering, and slitting. After forming, cells undergo rigorous testing to eliminate defective units, ensuring only consistent-performing cells proceed to subsequent stages. Testing includes capacity, internal resistance, temperature, and cycle life evaluations.

Cell Grading and Matching

Even within the same batch, cells exhibit subtle performance variations. Grading cells into groups with voltage, capacity, and internal resistance differences within 2% is crucial to prevent accelerated pack life degradation.

Integration and Assembly Process

Cell assembly is the critical process transforming graded cells into battery modules. Laser welding is the mainstream method due to its high reliability, low internal resistance, and resistance to detachment. In some scenarios, elastic metal contacts are used (eliminating welding and facilitating cell replacement, but carrying a risk of poor contact).

Quality Inspection and Validation

Finished battery packs undergo comprehensive testing, including performance evaluations, safety verifications, environmental adaptability assessments, and visual inspections. Safety testing simulates extreme conditions such as overcharging, over-discharging, short circuits, and crushing to ensure safe operation under all conditions.

III. Performance Evaluation Metrics for Lithium Battery Packs

Assessing lithium battery pack performance requires attention to three core parameters:

Configuration Method (P×S Configuration)

Configuration is typically denoted as “PxS,” where “S” represents the number of cells in series and ‘P’ represents the number of cells in parallel. For example, “1P24S” indicates 24 cells in series and 1 cell in parallel. Series connections increase voltage, while parallel connections increase capacity. The configuration determines the pack’s output characteristics.

Rated Capacity and Energy

Rated capacity (Ah) determines discharge duration, while rated energy (kWh) reflects total energy storage capability. The calculation formula is: Rated Energy (kWh) = Rated Capacity (Ah) × Nominal Voltage (V). These parameters directly determine whether the pack can meet the requirements of specific energy storage scenarios.

Maximum Rate and Weight

The maximum rate affects charging and discharging speed, while weight impacts installation and transportation convenience. These parameters require balanced selection based on specific application scenarios.

IV. Development Trends in Lithium Battery Pack Technology

Lithium battery pack technology is evolving in four primary directions:

Structural Innovation: CTP/CTC Technology

CTP (Cell to Pack) technology integrates cells directly into the battery pack, eliminating the module stage to enhance space utilization and energy density. CATL’s CTP technology reduces pack components by 40% while increasing energy density by 10%-15%.

CTC (Cell to Chassis) technology further integrates batteries directly into vehicle chassis, enabling unified floor and chassis design. Tesla’s CTC approach mounts batteries directly onto the chassis, substantially reducing component count.

Intelligent Management Upgrades

AI and IoT technologies enable smart alerts and predictive maintenance. Big data analytics combined with machine learning predict battery lifespan and failure risks, enhancing system reliability and longevity.

Thermal Management Optimization

Liquid cooling systems are increasingly prevalent, particularly cold plate liquid cooling and immersion cooling technologies. Research indicates optimized liquid cooling solutions can maintain temperature differentials within the battery pack ≤2°C, with maximum temperatures ≤32°C. Phase change material cooling technology also shows promising potential.

Manufacturing Process Innovation

High-precision techniques like laser welding and ultrasonic welding are widely adopted to ensure connection reliability and low internal resistance. Automated production line equipment enhances manufacturing precision and efficiency, while MES systems enable production data traceability and quality management.

V. Application Challenges and Solutions

Battery PACK technology still faces multiple challenges:

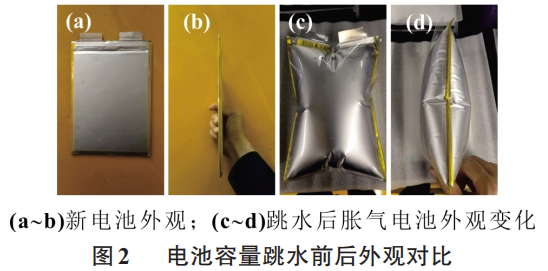

Safety Concerns

Thermal runaway risk remains the greatest safety hazard. Solutions include:

Improving flame retardants and thermal stabilizers to reduce fire and explosion risks

Optimizing structural design and manufacturing processes to enhance collision and crush resistance

Refining fire suppression plans and implementing multiple redundant designs

Cost Control Pressure

The PACK assembly accounts for 8-9% of power battery production costs, making it a key focus for cost reduction. Structural innovations (e.g., CTP/CTC technology) and process optimizations can significantly lower manufacturing expenses.

Consistency Assurance

Variations in cell performance can trigger the “shortest-cell effect,” compromising overall PACK lifespan. Precise cell sorting and matching algorithms are essential to ensure consistent characteristics within each module.

Maintenance and Recycling

CTP/CTC technologies face challenges in maintenance convenience and cost. Novel maintenance solutions and recycling systems must be developed to establish a closed-loop “production-use-recycling” cycle.

Lithium-ion battery pack technology is a multidisciplinary field encompassing electrochemistry, materials science, thermal management, and intelligent control. With the continuous growth in renewable energy storage demand, battery pack technology is evolving toward greater efficiency, enhanced safety, and increased intelligence.

Structural innovations (CTP/CTC), intelligent management (AI+BMS), and advanced thermal management technologies will become key drivers for future development. However, safety, cost control, and lifespan remain core challenges requiring ongoing solutions.

For industry practitioners, a deep understanding of PACK technology’s core principles and development trends will facilitate the creation of superior energy storage solutions. For users, mastering fundamental methods for evaluating PACK performance enables selection of products best suited to specific application needs.

With technological advancements and market expansion, lithium-ion battery PACKs will play an increasingly vital role in the global energy transition, providing critical technological support for sustainable development.