Lithium Iron Phosphate (LFP) Battery Technology

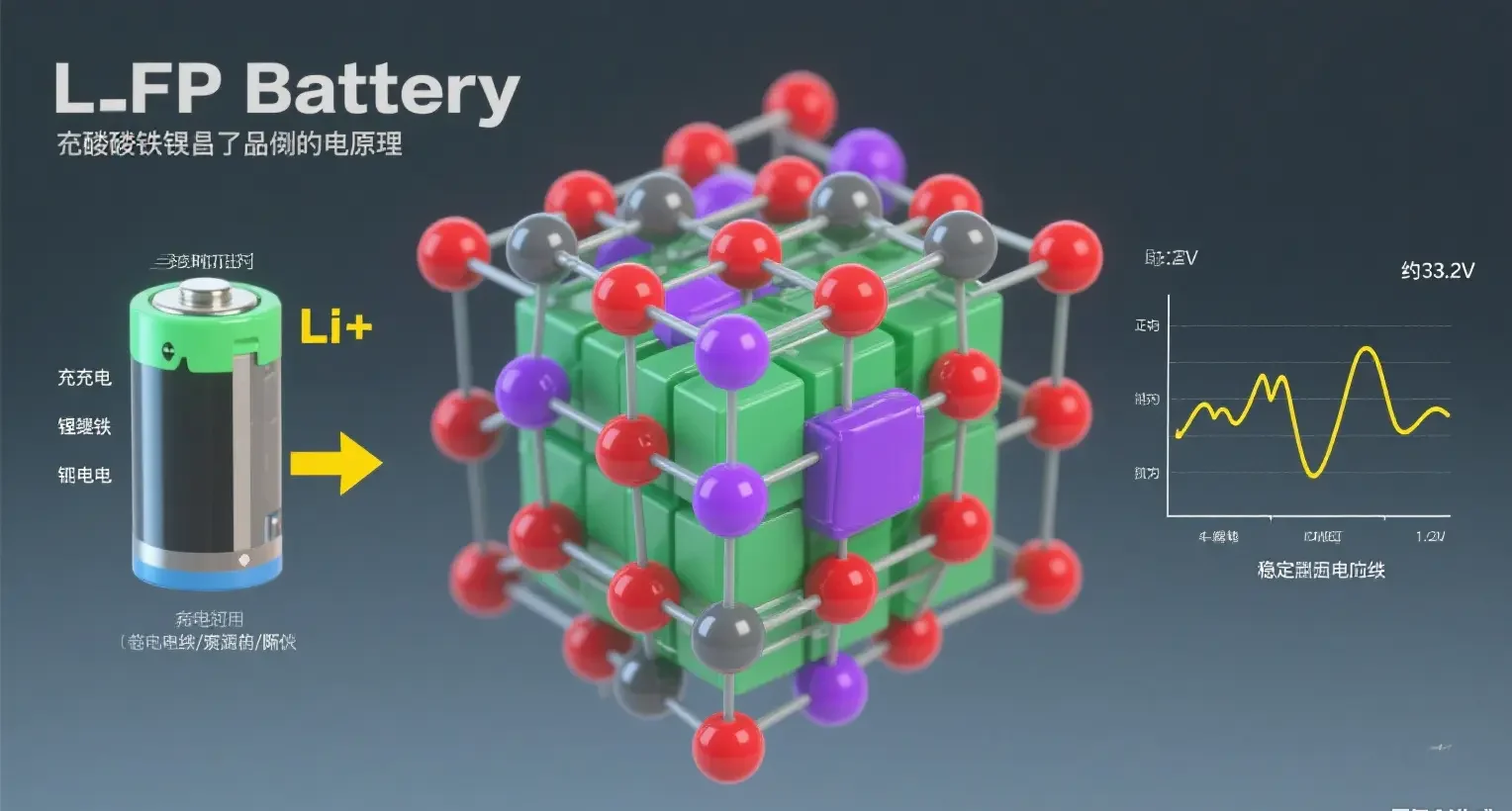

Lithium Iron Phosphate (LFP) Battery Core Structure: The Olivine Crystal Safety Code

The olivine structure of LiFePO₄ gives it intrinsic safety characteristics:

- PO₄³-tetrahedral skeleton: bond energy >500 kJ/mol (cornerstone of high temperature stability)

- One-dimensional lithium ion channel: diameter 0.37 nm (restricts orderly lithium ion de-embedding)

- FeO₆ octahedron: volume change during charging and discharging is only 3.7% (up to 10% for NCM)

Thermal stability comparison:

| Materials | decomposition temperature | oxygen release rate |

|---|---|---|

| LFP | >500℃ | 0 mmol/g |

| NCM811 | 200℃ | >2.5mmol/g |

The Double-Edged Sword of Performance: Engineering a Balance of Advantages and Challenges

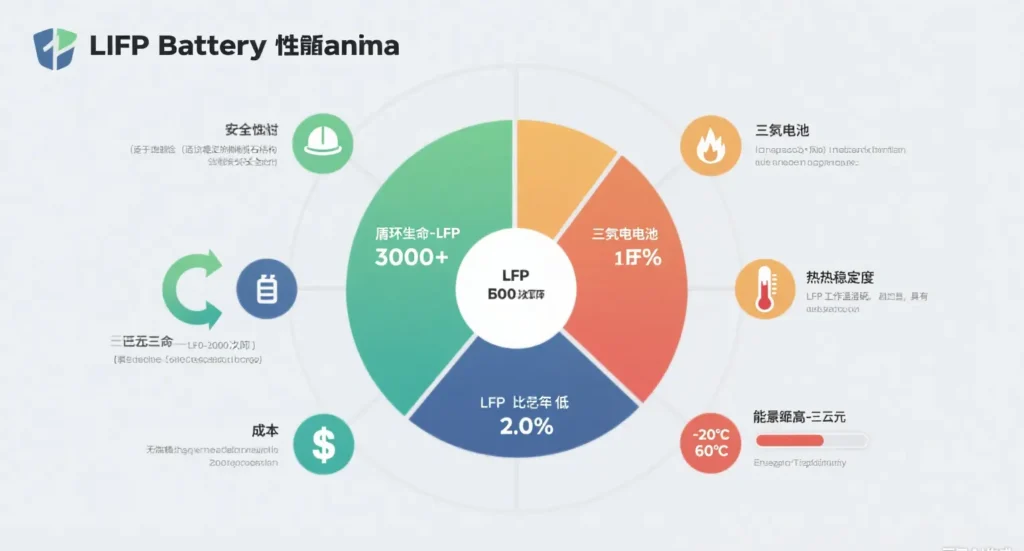

▶ Irreplaceable safety advantages

1. Thermal runaway threshold:

Pin prick test: temperature peak <200℃ (ternary >800℃)

Thermal diffusion test: >60min without open flame (national standard requirement >5min)

2. Cycle life limit:

- Power battery: >3000 times @ 80% SOH (45℃/1C)

- Storage battery: >12000 times (0.5C/25℃)

▶ Urgent performance bottlenecks to be broken through

1. Energy density ceiling:

- Theoretical value: 170mAh/g → actual pack 180Wh/kg

- Comparison: NCM811 pack up to 280Wh/kg

2. Low temperature kinetic hysteresis:

- -20°C capacity retention: 60% vs. 75% for ternary

- Root cause: Li-ion diffusion coefficient down to 10-¹⁵ cm²/s

Technology Evolution Path: From Material Modification to System Innovation

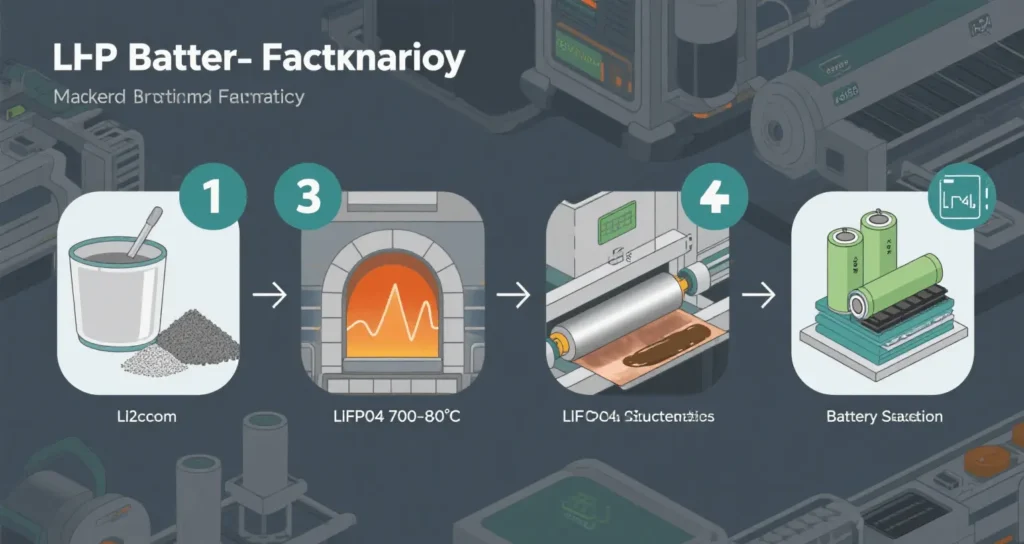

1. Material-level optimization

Nano + Carbon Coating:

- Particle size <100nm → Specific surface area >20m²/g

- Carbon layer <5nm → Conductivity increase by 10³ times

Cation doping:

- Mg²⁺ replaces Fe²⁺ → capacity retention rate +15% at low temperature

- NDT Patent: -20℃ capacity>75%

2. Revolutionary breakthrough in structure

| parameters | Traditional LFP | blade battery |

|---|---|---|

| space utilization | 60% | 90% |

| volume energy density | 300Wh/L | 400Wh/L |

| Needle penetration rate | 70% | 100% |

3. System integration innovation

- CTP module-less technology:

- 15% weight reduction + 10% cost reduction

- Thermal management upgrade: Thermal conductivity of liquid-cooled plate >5000W/mK

Golden section of application scenarios

1. New Energy Vehicles

Economy model: system cost <$90/kWh (e.g., Wuling Hongguang MINI)

Mid- to high-end model: 600km range + 5-minute thermal runaway warning (BYD Han EV)

Commercial vehicle sector: 500,000km life (Yutong Bus actual operation data)

2. Energy Storage System

Grid-level energy storage:

cost per kWh <$0.07/kWh (Qinghai 100MW project)

calendar life >20 years (decay rate <0.01%/day)

communication base station:

Huawei intelligent temperature control: -40℃~60℃ all-climate operation

3. Special fields

Deep-sea equipment: >1000m voltage resistance (Struggler power supply)

Mining equipment: IP68 protection + intrinsic safety explosion-proof certification

Future direction of technology integration

1.Solid-state electrolyte composite:

LFP+Sulfide SSE → Energy density breaks through 250Wh/kg

2.Sodium-iron hybrid ion battery:

Na⁺/Li⁺ co-embedded → raw material cost reduced by 30%.

3.AI life prediction:

Neural network model based on 20,000 sets of cycle data (error <3%)

With 58% global market share by 2023 (SNE Research), LFP’s safety genes have become the technological baseline for power batteries.