Methods to Extend Drone Battery Life

Insufficient flight time should not be a bottleneck for drone applications. The key to unlocking extended endurance lies in proper battery management strategies.

As a lithium battery engineer, I deeply understand the anxiety drone users feel when suddenly encountering low-battery warnings mid-flight. The frustration of having to abandon the perfect shooting angle and rush back to base often stems not from the battery’s capacity itself, but from misunderstandings about battery characteristics and energy consumption management.

In fact, through scientific battery management strategies, even standard-capacity batteries can significantly extend a drone’s actual flight time and battery cycle life. This article analyzes three key techniques from a professional perspective to help you maximize your drone’s battery endurance.

I. Pre-Flight Optimization: Preparing Your Battery Thoroughly

Temperature Management: Unlocking Optimal Battery Performance

Battery temperature significantly impacts performance. Experimental data shows that using batteries directly at -10°C reduces discharge efficiency by 30%. This not only shortens flight duration but may also trigger lithium dendrite growth, permanently reducing battery lifespan.

Professional Solutions:

- Pre-flight Warming: Allow batteries to acclimate to 15-25°C before flight. Use insulated bags or official warming devices if necessary. Premium drones like DJI’s M4 series and M3 Enterprise series support onboard battery heating.

- Low-Temperature Charging Strategy: Before charging below 0°C, preheat batteries to above 10°C to prevent capacity drop.

Functional Streamlining: Eliminating Hidden Energy Consumption

Simultaneously running multiple advanced drone functions significantly increases power consumption. Through rational configuration, energy usage can be reduced without compromising core mission capabilities.

Energy Optimization Measures:

- Selective Obstacle Avoidance Activation: Enable obstacle avoidance only in the flight direction to reduce continuous sensor processing power consumption.

- Video Transmission Resolution Adaptation: Use standard-definition transmission during transit flights, switching to high-definition only during filming.

- Disable Non-Essential Equipment: Turn off non-essential devices like LED indicators and low-power cameras during transit flights.

Flight Path Planning: Maximizing Flight Efficiency

Unplanned flight routes are a primary cause of energy waste. Scientific route planning significantly enhances operational efficiency per flight.

Planning Strategies:

- Prioritize Direct Routes: Design a “straight takeoff → target position → straight return” route to avoid redundant segments.

- Reserve Power Mechanism: Maintain at least 40% battery reserve for return flights during headwind conditions to prevent endurance issues caused by wind resistance.

II. In-Flight Operations: The Art of Energy-Efficient Flying

Steady-Speed Flight: Reduce Motor Load

Aggressive maneuvers force motors to operate at sustained high loads, significantly increasing energy consumption. Maintaining smooth operations is key to extending flight duration.

Key Operational Points:

- Control Speed Fluctuations: Stabilize vertical and horizontal speeds at 1-2 meters per second to avoid power spikes caused by sudden joystick inputs.

- Utilize Slow Mode: Entry-level drones can enable “Slow Mode,” which automatically limits maximum throttle values, reducing energy fluctuations caused by operation.

Minimize Hovering: Avoid Inefficient Power Consumption

Contrary to common belief, drone hovering consumes more power than steady-speed flight. Motors must continuously adjust RPM to maintain position, making this “idle” state extremely inefficient.

Hovering Alternatives:

- Slow Movement Substitution: Adjust parameters while moving the drone at 0.5 m/s, which consumes less energy than complete hovering.

- Altitude-Holding Orbit Applications: Use altitude-holding orbit mode for fixed-scene filming to capture multiple angles while avoiding the high energy consumption of pure hovering.

Environmental Adaptation: Reduce External Resistance

Flight altitude and weather conditions significantly impact energy consumption. Lower altitudes typically offer less wind resistance, while strong winds, rain, or snow dramatically increase the power system load.

Environmental Utilization Strategies:

- Altitude Optimization: Balance flight altitude based on mission requirements; avoid unnecessary climbs.

- Weather Selection: Avoid flying in high-wind conditions; use professional weather apps to check flight conditions.

III. Post-Flight Maintenance: Ensuring Long-Term Battery Health

Scientific Charging and Discharging: Avoid Extreme Conditions

Overcharging (>95%) and over-discharging (<20%) are primary causes of lithium battery capacity degradation. A reasonable charging and discharging strategy can significantly extend battery cycle life.

Charge/Discharge Specifications:

- Charge Range Control: For daily use, set the charging upper limit to 80% and the discharge lower limit to 30% to reduce battery stress.

- Post-Flight Handling: Allow batteries to cool for 15 minutes after heating before recharging. For short-term storage, maintain 20%-30% charge; for long-term storage (over 1 month), keep 40%-60% charge.

- Balance Charging Application: Utilizing the “Balance Charge” mode on smart chargers like the D12000iE stabilizes cell voltage differences within 0.03V. Field tests indicate this practice slows capacity degradation by 42%.

Regular Maintenance: Data-Driven Decision Making

Professional Maintenance Strategy:

- Health Monitoring: Use apps like DJI Pilot 2 to monitor real-time cell parameters including voltage, temperature, and cycle count. When the battery interface displays an “!” warning after reaching its cycle limit, perform capacity calibration.

- Deep Maintenance: Conduct deep maintenance every 50 charge/discharge cycles, including cell balancing checks and connector tightness inspections. Retire batteries promptly when actual capacity falls below 80% of rated capacity.

- Visual Inspection: Weekly checks for battery swelling (discontinue use if >3mm), connector oxidation (clean with alcohol swabs), and cable damage.

IV. Hardware Upgrades: Technology-Driven Breakthroughs in Flight Duration

High-Energy-Density Batteries

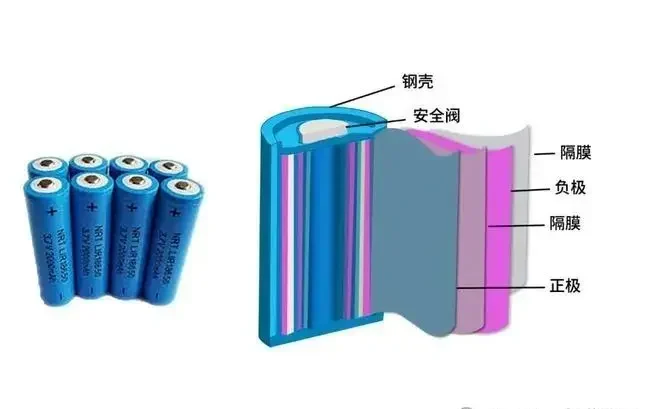

Advancements in battery technology provide the hardware foundation for extended flight times. Currently, silicon-carbon anode batteries have increased energy density by 20%-30%, extending single-charge flight duration by 40 minutes.

Recommendations:

- Lithium Polymer Batteries: High energy density and low self-discharge rate, suitable for most aerial photography scenarios.

- Lithium Iron Phosphate Batteries: Enhanced over-discharge tolerance, remain active even at 2.5V voltage, suitable for high-reliability applications.

- High-Voltage LiHV Batteries: In agricultural crop protection, upgrading from traditional 2200mAh batteries to 4000mAh high-voltage LiHV batteries extends single-flight operation time from 18 to 28 minutes.

Intelligent Power Management System

Advanced power management systems optimize energy distribution, with some incorporating voltage stabilization to extend component lifespan.

Technological Frontiers:

- Hybrid Power Systems: Combining lithium batteries with supercapacitors, where supercapacitors handle power fluctuations, enhances output stability during lithium battery discharge.

- Smart BMS: Real-time monitoring of cell health status, automatic balancing of charge distribution, and reduced risk of single-cell over-discharge.

V. Special Measures for Low-Temperature Environments

Low temperatures are the primary factor affecting battery performance. Special countermeasures are required for flights in winter or high-altitude cold regions:

Low-Temperature Response Plan:

- Fully Charged Flight: Ensure batteries are fully charged before use in low-temperature environments (<5°C) to compensate for voltage drops caused by increased internal resistance.

- Preheat Assurance: Utilize the built-in heating systems of batteries like TB65/TB30, or use insulated bags to preheat batteries to above 20°C.

- Flight Duration Control: Reduce single-flight duration and closely monitor battery capacity and voltage, as low temperatures may cause inaccurate battery capacity readings.

The key to achieving long-lasting endurance lies not in carrying more batteries, but in scientifically managing every watt-hour of power. From meticulous pre-flight preparation to energy-efficient operation during flight, and professional post-flight maintenance, every step impacts the final endurance performance.

With the maturation of solid-state battery technology and AI-powered intelligent management systems, future drones will see even greater breakthroughs in endurance. But until then, mastering these battery management techniques remains the most effective way to unlock a drone’s full potential.