Reasons for eVTOL battery heating in 2025

I. Extreme working condition challenges of eVTOL batteries

1. Life and death balance between performance and safety

Ultra-high rate discharge: 8-14C instantaneous discharge is required in the take-off and landing phase (compared with <5C for electric vehicles), and the polarization heat is increasing by a square degree;

Low pressure environment: the air pressure drops to 70kPa at an altitude of 3000m, the air heat dissipation efficiency decreases by 40%, and the temperature rises accelerates by 15%;

Lightweighting yoke: the requirement of energy density >300Wh/kg forces to give up the active heat dissipation system, and to rely on the passive thermal management.

2. eVTOL battery thermal runaway “90 seconds golden window”.

Within the closed space of the aircraft, it takes only 37 seconds for the battery to go out of control until the cabin is filled with smoke, and the effective escape time is <15 seconds;

ternary batteries can burst into flames at 800℃ within 3 seconds, and lithium iron phosphate releases highly toxic hydrogen fluoride gas.

II. Decomposition of heat production mechanism: life and death transition from entropic heat to polarized heat

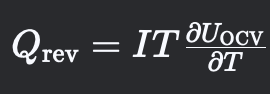

1. Reversible entropic heat: “secondary role” in high-multiplication scenarios

Physical nature: entropic heat absorption and excretion triggered by lithium ion embedding/de-embedding

Formula:

SOC Dependency:

| SOC interval | Discharge entropy heat symbol | Impact on temperature rise |

|---|---|---|

| >80% | Negative value (endothermic) | Suppressing temperature rise |

| <30% | Exactly (exothermic) | accelerate global warming |

Realistic limitations: eVTOL current density in the take-off and landing stage is >5A/cm², polarization heat accounts for more than 90%, and entropy heat effect is masked.

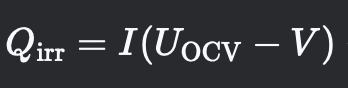

2. Heat of polarization: the “fatal protagonist” of high rate discharge.

The core term of the heat equation:

→ current-squared growth

| Heat source type | Mechanism of generation | Hazards of eVTOL scenarios |

|---|---|---|

| Ohmic resistance heat | Collector fluid/electrolyte impedance (I²R) | 3C discharge temperature rise reaches 30.1°C5 |

| charge transfer impedance | SEI membrane ion migration barrier | Impedance rises by 200% at low temperatures |

| concentration polarization heat | Li⁺ diffusion lag forms concentration gradient | Local overheating caused by high magnification |

| adverse reaction heat | Dendrite growth/electrolyte decomposition | Triggering a chain reaction of thermal runaway |

Experimental corroboration: the center temperature of the battery reaches 55.1℃ during 3C discharge, and the temperature difference between the poles is 1.8℃.

III. Chain reaction of thermal runaway: from SEI collapse to diaphragm meltdown

1. Fifth-order thermal runaway model

SEI decomposition 90-120℃ –> Negative electrode-electrolyte reaction 150℃ –> Diaphragm melting 135-165℃ –> Positive electrode oxygen precipitation 200℃ –> Electrolyte deflagration 250℃.

2. eVTOL exclusive risk amplifier

- Low-pressure delayed heat dissipation: heat convection efficiency decreases → temperature rise rate increases by 20%;

- Mechanical vibration-induced micro-short circuit: vibration acceleration in the take-off and landing phase >5G, exacerbating dendrite puncture;

- Dead zone at the end of the capacity section: SOC <20% internal resistance increases dramatically, and the heating power in the early stage of the discharge rises by 50%.

IV. Engineering Breakthrough: Material Innovation and Thermal Management Revolution

1. Material-level solutions

| technical approach | Core Innovation | Improved thermal performance |

|---|---|---|

| Infinite ear structure | Full-pole ear design reduces internal resistance by 30% | 14C discharge temperature rise < 45°C |

| solid electrolyte | Ionic conductivity of sulfide system > 10 mS/cm | Eliminate the risk of electrolyte decomposition |

| Pre-lithiated silicon anode | Compensating for active lithium loss | Cycle life > 1000 times |

2. Key technologies for thermal management

- Phase change material (PCM): paraffin/expanded graphite composite material, latent heat>180J/g, heat absorption efficiency is 5 times that of air-cooling;

- nano-heat pipe array: thermal conductivity up to 5,000W/(m-K), temperature difference under 3C discharge <2℃;

- intelligent heat barrier layer: automatic expansion isolates oxygen when the temperature is >100℃, and slows down the spread of fire by 300%.

3. System-level safety design

- Multi-field coupling simulation: electric-thermal-mechanical coupling model predicts thermal runaway time with an error of <3%;

- Fault Tree Analysis (FTA): identifies “vibration+low SOC+high multiplicity” triple superimposed risk scenarios;

- Redundant design of escape pods: sideways ejector pods avoid propellers, and the success rate of escape is increased to 89%.

Conclusion: The Essence of Thermal Safety is the Precise Regulation of Energy Flow

When the electrodeless lug structure locks the 14C discharge temperature rise within 45℃, and when the phase change material eats up the polarization heat with 180J/g latent heat – the thermal management race of eVTOL battery has shifted from “passive defense” to “active energy planning”. Energy planning”.

The ultimate formula:

eVTOL Battery Safety = Material Intrinsic Thermal Resistance × Thermal Management Efficiency × Fault Tolerant Design

The competitiveness of China’s solutions is hidden in the product of these three variables:

- Qingtao Energy sulfide electrolyte blocks chain reaction;

- Rui En New Energy nano heat pipe realizes even temperature control;

- Yihang intelligent ejection capsule reshapes escape logic.

The data predicts that when all-solid-state eVTOL batteries are mass-produced in 2027, the thermal runaway trigger temperature will increase from 180°C to >300°C, and the airborne accident rate will drop to the level of civil airliners4.