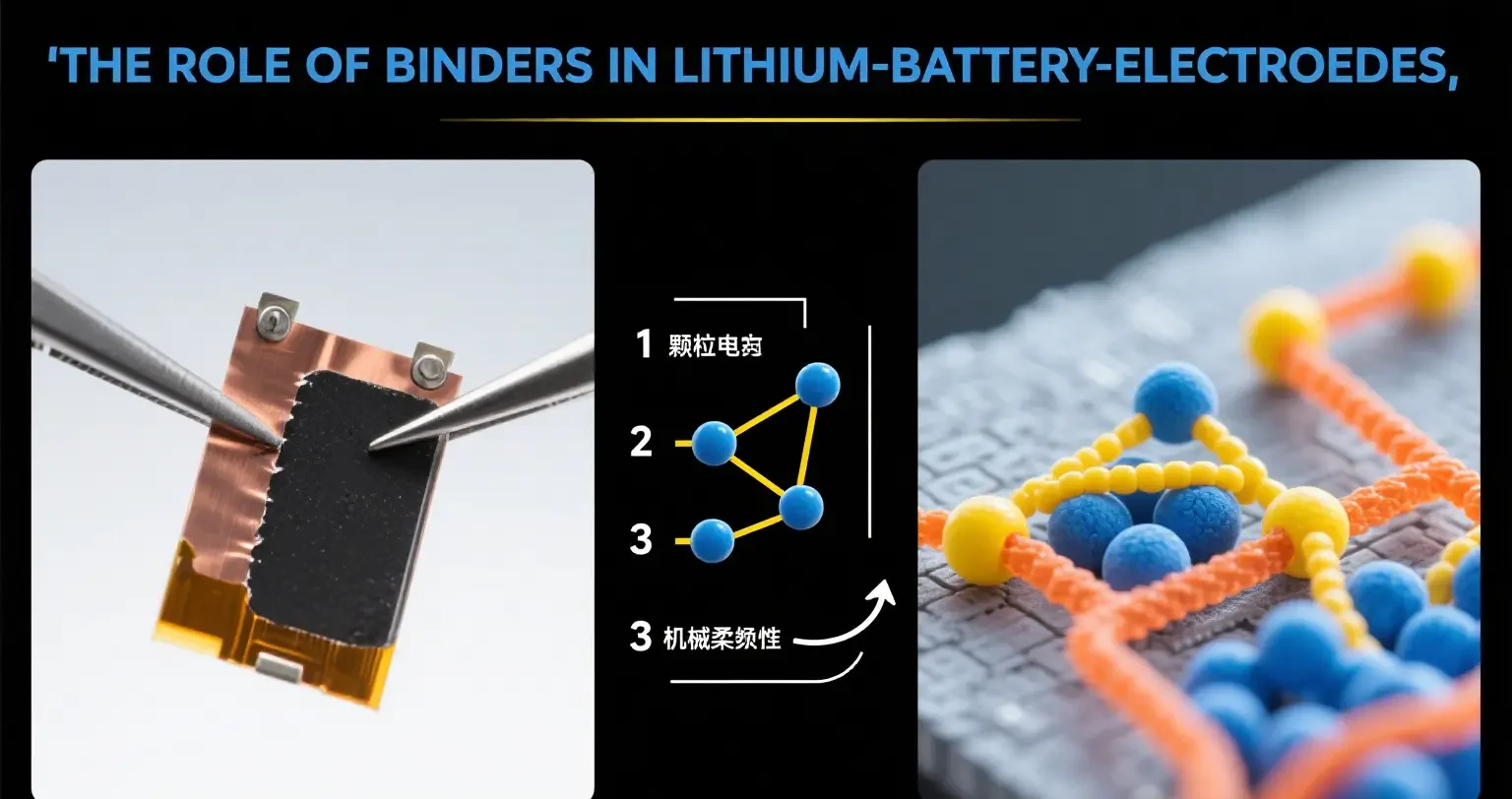

The Role of Binders in Lithium Battery Electrodes

Though comprising only 1%-5% of electrode materials, binders are critical components determining battery performance and lifespan.

As lithium battery engineers, we fully understand the pivotal role of binders in electrode manufacturing. Though typically comprising only 1%-5% of the electrode’s solid content, it functions like the “cement” in construction—firmly bonding active materials and conductive agents together as “bricks,” while integrating with current collectors (aluminum or copper foil) to form a stable, complete electrode structure.

I. Four Core Functions of Binders in Lithium Batteries

Bonding and Film Formation

The fundamental function of a lithium battery binder is to form a uniform thin-film network after electrode slurry drying. This network encapsulates and firmly bonds active material particles (such as ternary materials, lithium iron phosphate, graphite, etc.) with conductive agents (such as SP, CNT), creating a complete electrode coating. This ensures the electrode remains intact and prevents cracking or delamination during subsequent manufacturing processes like calendering, slitting, winding, and stacking.

Maintaining Mechanical Stability

During lithium battery charging and discharging, active materials undergo significant volume expansion and contraction—silicon-based materials in particular can experience volume changes exceeding 300%. An excellent binder must possess good elasticity, toughness, and adhesion to buffer stresses from these volume changes. This prevents the electrode structure from pulverizing or fracturing due to repeated expansion and contraction, thereby maintaining electrode integrity.

Ensuring Electrochemical Stability

The binder must remain chemically and electrochemically inert within the battery’s operating voltage window (0–4.5V vs. Li/Li⁺). It must not undergo side reactions with the electrolyte, decompose to form impedance layers, or consume lithium ions, as these would cause capacity decay, increased internal resistance, and other issues.

Providing Ion/Electron Transport Pathways

Certain novel functional binders (such as conductive polymers) also offer additional transport pathways for lithium ions (Li⁺) and electrons (e⁻). This helps reduce electrode internal resistance and enhances the battery’s rate performance.

II. Mainstream Binder Material Systems and Characteristics

Currently, the market primarily offers two categories of binders: oil-based systems and water-based systems:

Table: Performance Comparison of Mainstream Lithium-ion Battery Binders

| Binder Type | system | Primary Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| PVDF | oily | Positive electrode | Excellent electrochemical stability and strong adhesion | Requires the use of NMP solvent, which is costly and environmentally unfriendly. |

| SBR | water-based | negative electrode | Highly elastic, suitable for materials with significant volume changes | Insufficient adhesion when used alone |

| CMC | water-based | Negative electrode (for use with SBR) | High viscosity, excellent dispersibility | Poor flexibility |

| PAA | water-based | negative electrode | Strong adhesion, suitable for silicone-based materials | relatively high cost |

Oil-Based Binder Systems

PVDF (polyvinylidene fluoride) is the most commonly used binder for cathodes, offering excellent electrochemical stability and adhesion properties. However, its primary drawback is the requirement for N-methylpyrrolidone (NMP) as a solvent. This solvent is toxic and flammable, posing significant environmental and safety hazards.

Water-Based Binder Systems

Water-based binders utilize water as the dispersion medium, offering greater environmental safety and becoming a current R&D priority. Key components include:

SBR (Styrene-Butadiene Rubber): Features a unique core-shell structure, exhibiting exceptional adhesion properties with anode materials. It provides excellent flexibility to electrodes, enabling them to accommodate deformation during charge-discharge cycles.

CMC (Sodium Carboxymethyl Cellulose): Typically used in conjunction with SBR, it provides high viscosity and excellent dispersibility.

PAA (Polyacrylic Acid): Exhibits strong adhesion to silicon-based materials and effectively mitigates the volume effect of silicon particles.

III. Reasons for Using Both CMC and SBR in Graphite Anodes

In graphite anodes, both CMC and SBR binders are typically used simultaneously. This combination achieves synergistic effects:

- CMC provides initial viscosity and dispersibility: Ensuring slurry uniformity and processing performance

- SBR provides flexibility and elasticity: Accommodating volume changes in graphite during charge-discharge cycles

- Complementary Advantages: The rigid structure of CMC combined with the flexible properties of SBR ensures both structural stability of the electrode and sufficient toughness.

This combination approach meets the process requirements for negative electrode slurry while ensuring the structural integrity of the electrode during long-term cycling. It represents the most cost-effective solution currently available.

IV. Technological Innovations in Functional Binders

Conductive Polymer Binders

CATL has applied for a patent on a novel binder comprising polymers A and B in a mass ratio of (14–18):(2–6). Polymer B contains modified polyaniline, while polymers A and B form a conductive network structure through intermolecular forces. This binder exhibits excellent flexibility, conductivity, adhesion, hydrophilicity, and chemical stability. It facilitates rapid charging in lithium-ion batteries while mitigating lithium dendrite formation.

Ion-Conductive Binder

Researchers developed an ion-conductive grafted polymer binder (GG-g-PAM) by grafting polyacrylamide (PAM) onto an ion-conductive guar gum (GG) backbone. This binder exhibits high ionic conductivity, dissipates significant mechanical stress, and enhances lithium-ion diffusion kinetics in silicon anodes during cycling.

Composite Binder System

Zhejiang University developed a polymer-inorganic nanocomposite binder integrating polymers with layered inorganic nanomaterials. Characterized by high bonding strength and rapid lithium-ion transport, this binder simultaneously enhances the specific capacity, cycling stability, and rate performance of lithium-ion batteries.

V. Modification Strategies and Development Trends of Water-Based Binders

With increasing environmental requirements, water-based binders are emerging as a key development focus. A research team from Xi’an Jiaotong University systematically reviewed modification strategies for water-based binders:

- Improving interface compatibility: Enhancing interactions between the binder and active materials through molecular design

- Facilitating ion transport: Introducing ion-conductive groups to provide lithium-ion transport pathways

- Extending cycle life: Strengthening the binder’s mechanical strength and elasticity to accommodate volume changes

The primary challenge for water-based binders lies in balancing bonding strength, flexibility, and electrochemical performance while maintaining cost competitiveness.

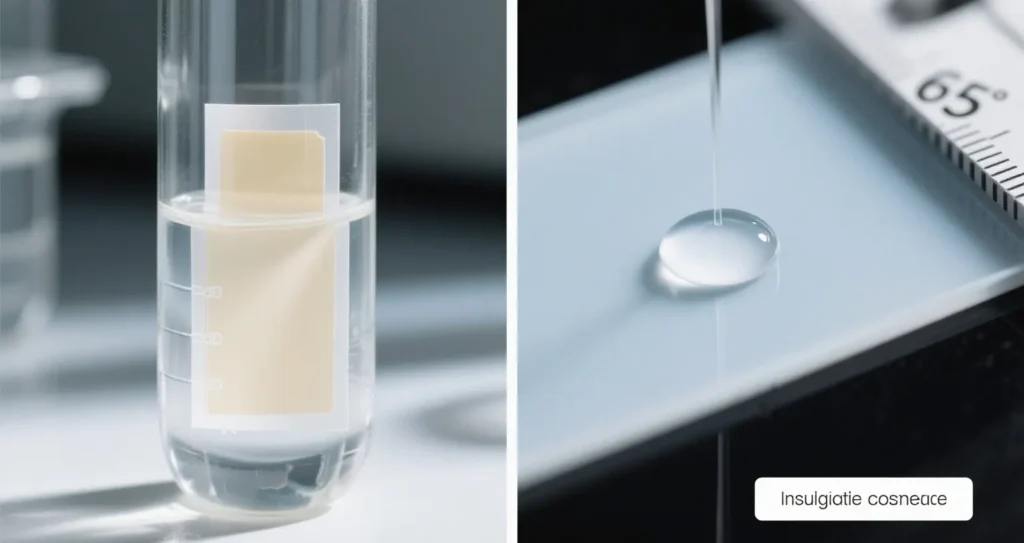

VI. Key Performance Indicators for Binder Evaluation

The key technical indicators for evaluating binder performance include:

- Peel Strength: Measures bonding strength, typically requiring values above 6.0 N/m

- First Cycle Efficiency: Initial charge/discharge efficiency, impacting the battery’s ultimate capacity

- Internal Resistance: Directly affects battery rate capability; high-quality binders should exhibit values below 25 mΩ

- Cycling Retention Rate: Capacity retention after 500 cycles should exceed 85%

VII. Application Cases and Performance

Rongdong New Materials’ FA106 anode binder demonstrates outstanding performance: peel strength reaches 6.3 N/m, initial efficiency peaks at 89.5%, capacity achieves 1535.0 mAh/g, and internal resistance is only 23.8 mΩ. After 500 cycles of 1C charge and 10C discharge, capacity retention reaches 86.3%.

Another product, the S08 anode binder, also delivers outstanding performance: peel strength of 6.0 N/m, initial efficiency of 90.5%, capacity of 1550.0 mAh/g, internal resistance of 22.5 mΩ, and a capacity retention rate of 91.3% after 500 cycles of 1C charge and 10C discharge.

VIII. Selection Recommendations and Future Outlook

Considerations for Adhesive Selection

When selecting adhesives, the following factors must be comprehensively evaluated:

- Active Material Type: Silicon-based materials require adhesives with higher elasticity and bonding strength

- Process Compatibility: Compatibility with existing production line equipment

- Cost Factors: Achieving the optimal balance between performance and cost

- Environmental Requirements: Compliance with environmental regulations and sustainable development principles

Technological Development Trends

Future adhesive technology will evolve in the following directions:

- Multifunctional Integration: Single adhesives providing bonding, conductivity, and interface stabilization simultaneously

- Intelligent Design: Accelerating novel adhesive development through molecular simulation and artificial intelligence

- Bio-based Materials: Developing renewable bio-based adhesive materials to reduce environmental footprint

- Adaptation to High-Capacity Systems: Creating adhesives suited for next-generation high-capacity electrodes like silicon-based and metallic lithium