Three Steps to Solid State Battery Manufacturing in 2025

I.The three major steps of solid-state battery manufacturing electrode and solid-state electrolyte diaphragm manufacturing: the material system determines the process path

Solid-state battery electrode and electrolyte diaphragm manufacturing is the cornerstone of the process selection and material properties deeply coupled:

| material system | Key Process Challenges | Innovative solutions | Representative enterprise technology route |

|---|---|---|---|

| sulfide | Air sensitivity (H₂S generation) | All-dry process (solvent-free) + glove box-grade environment (H₂O < 0.1 ppm) | Toyota, Samsung SDI |

| oxide | High-temperature sintering (>1000°C) results in high interface impedance. | Thin film deposition technology (magnetron sputtering/PLD) + nano interface layer (LiNbO₃) | QuantumScape, Hui Neng |

| polymer | Low ionic conductivity at room temperature (10⁻⁴ S/cm) | Blended plasticization (PEO-LiTFSI) + cross-linked network | BMW- Solid Power |

Analysis of key process steps

1 Deposition sequence game:

- Option A: Collector → cathode slurry coating → solid electrolyte layer deposition → drying/calendering

- Option B: Carrier tape → solid electrolyte film formation → cathode slurry coating → drying/calendering

Engineering selection basis: electrolyte and electrode interface compatibility and thermal expansion coefficient matching degree

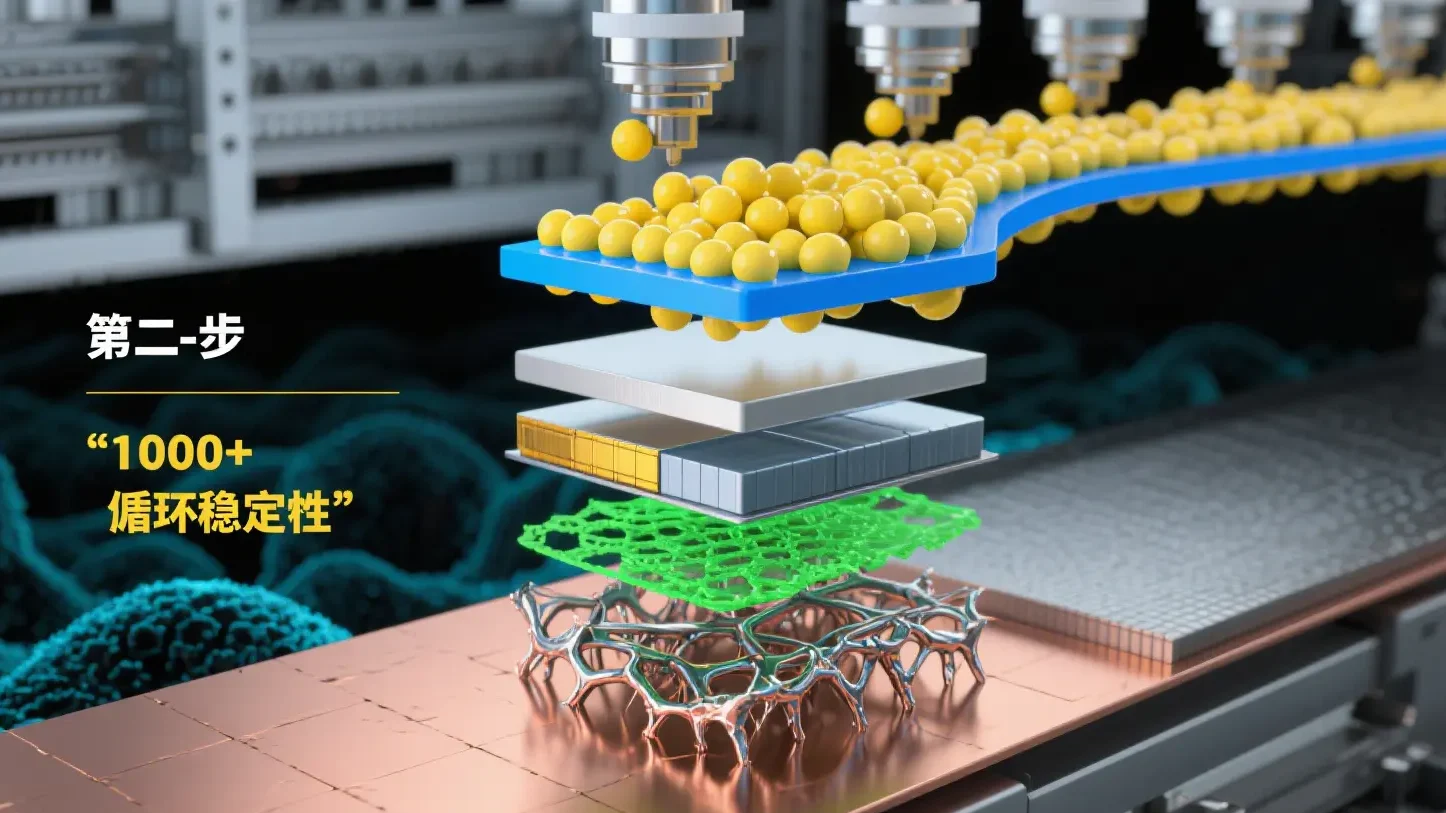

2. Lamination to strengthen the interface:

- Adopt hot roller pressing (temperature 80-150 ℃, pressure 5-20 MPa) to realize the cathode-electrolyte-anode atomic level contact

- Target: interface impedance <10 Ω-cm² (liquid battery benchmark ~5 Ω-cm²)

II. The three major steps of solid-state battery manufacturing battery cell assembly: from stacking design to encapsulation revolution

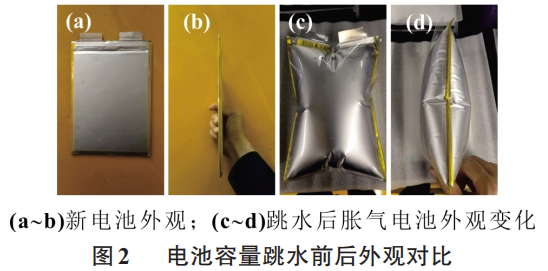

1. Choice of structural form: soft pack dominant, cylindrical breakthroughs

- Soft pack battery (mainstream): suitable for brittle oxide/sulfide electrolyte, uniform pressure distribution

- Cylindrical battery (potential):

- Polymer system has been realized (e.g. Solid Power)

- Sulfide system needs to solve flex crack (Panasonic developed flexible sulfide composite film)

2. Evolution of stacking technology

| stacking method | Technical features | Energy density improvement | mass production difficulty |

|---|---|---|---|

| single-pole parallel connection | Traditional layering (similar to liquid batteries) | benchmark | Low (compatible with existing devices) |

| Bipolar stacking | Collective fluid double-sided coating, unit series connection | ↑30-50% | Extremely high (requires perfect consistency) |

Bipolar stacking core barriers:

- Bipolar collectors need to be resistant to high-voltage corrosion (>5V) → Use of Al/PET/Al composite foils

- Zero short-circuit tolerance between cells → Dependence on ≤1μm electrolyte layer uniformity

3. Encapsulation innovations

- All-solid-state battery advantage: 40% shorter process by omitting liquid injection and degassing steps

- Highly hermetic encapsulation:

- Laser welding (sulfide batteries) Leakage rate <10-⁶ Pa-m³/s

- Polymer heat sealing (polymer batteries) Peel strength >50 N/cm

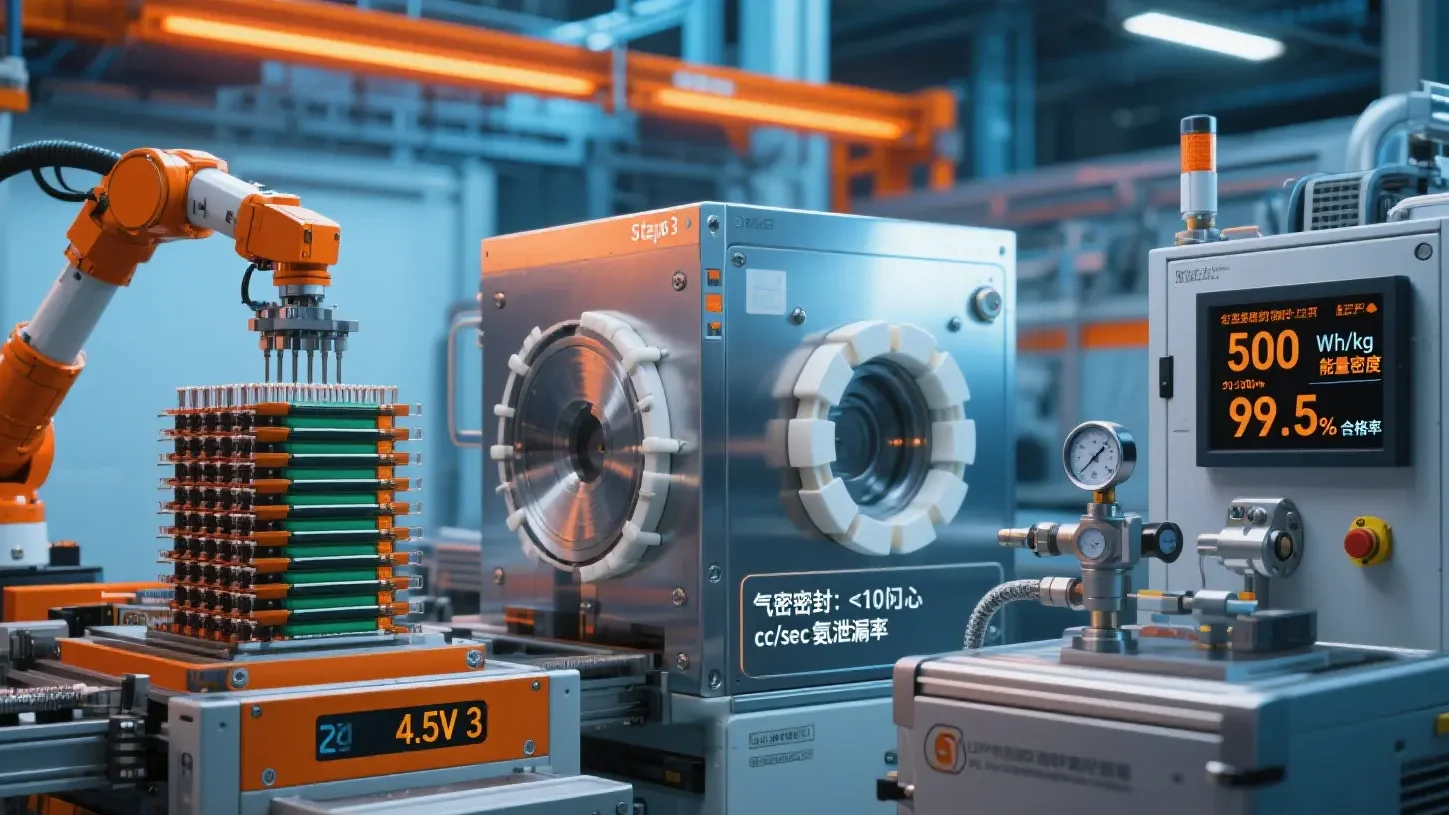

III. Battery cell post-processing: the efficiency revolution of formation and testing

1. Formation process optimization

- Liquid battery pain point: three weeks of formation (SEI formation) + aging, cost accounted for 25%

- Solid state battery breakthrough:

- Sulfide/Oxide: no need for SEI formation → shorten formation time to 24 hours

- Lithium metal anode: zero formation (no lithium loss)

- Key step: interface activation (pressurized to 3-5 MPa, temperature 60-80°C)

2. New Paradigm in Aging and Testing

| project | liquid battery | solid-state battery | technological gains |

|---|---|---|---|

| aging time | 7-21 days (detection of micro-short circuits/gas production) | ≤3 days (intrinsic safety reduces the probability of failure) | Capacity utilization rate ↑50% |

| Internal resistance testing | AC impedance (EIS) | Direct current polarization method (avoiding interface capacitance interference) | Accuracy ↑ to ±0.5 mΩ |

| thermal runaway screening | Adsorption Calorimetry (ARC) | Laser triggering + infrared thermal imaging (non-destructive) | 100% inspection becomes possible |

IV. Mass Production Frontier: Process Roadmap for Head Enterprises

1. Toyota (sulfide):

All-dry electrode process: dry powder mixing → hot press molding → roll-to-roll lamination

2026 target: 10 GWh capacity, cost $80/kWh

2. QuantumScape (oxide):

ceramic diaphragm sputtering + anode in-situ deposition

Breakthrough: >1000 cycles (C/3, 25°C)

3. Phonon (oxide/polymer):

Bipolar stacking + flexible package

Tranquility improvement: interface defect rate <0.1% (measured in 2025)

V. Future trends: process innovation to drive the cost inflection point

1. Dry electrode technology:

eliminates solvent recovery → energy consumption ↓60% (Tesla Maxwell patent)

2. Roll-to-roll integration:

cathode-electrolyte-anode continuous deposition (precision ±1μm)

3.AI quality control system:

based on online optical inspection + deep learning real-time identification of lamination defects

Engineer’s assertion: when dry electrode + bipolar stacking + zero chemical process to achieve mass production integration, solid state battery manufacturing cost will approach the liquid battery ($100/kWh threshold), opening the TWh era.