UAV Lithium Battery Technology

Energy density, discharge rate, and thermal management form the three core pillars of UAV lithium battery technology, directly determining flight performance and safety boundaries.

As lithium battery engineers, we understand that power batteries serve as the “heart” of drones, with their performance directly influencing flight endurance, payload capacity, and safety. Unlike standard consumer lithium batteries, drone power batteries must strike a precise balance between high-rate discharge capability, lightweight design, and environmental adaptability.

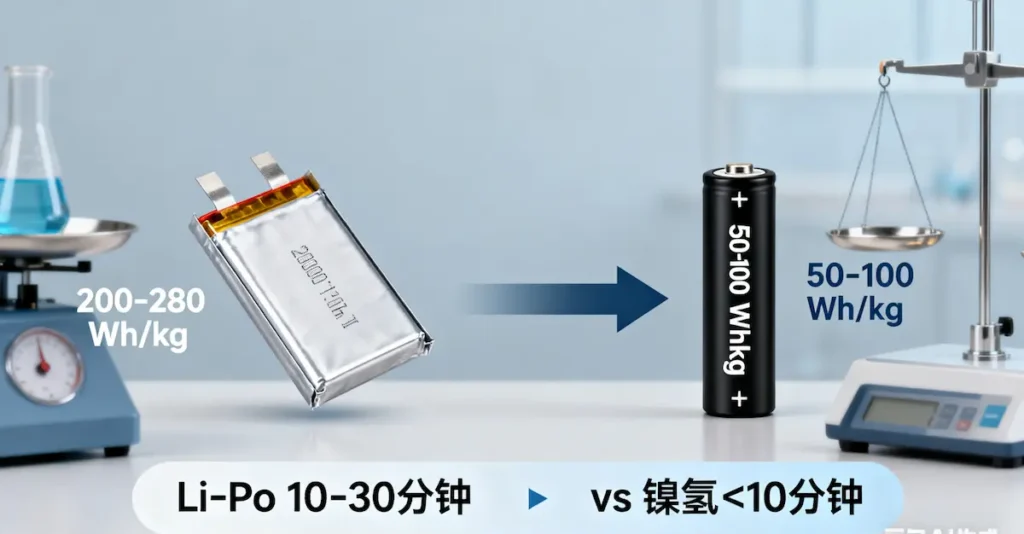

Currently, mainstream drones utilize lithium polymer batteries (Li-Po) as their power source. These batteries typically achieve energy densities of 200-280 Wh/kg, far surpassing the 50-100 Wh/kg of traditional nickel-metal hydride batteries. This enables drones to achieve 10-30 minutes of continuous flight time. The latest high-energy-density batteries under development can even reach 400 Wh/kg, boosting drone endurance by 20%-40%.

I. Cell Technology: Chemical Systems and Performance Characteristics

Cathode Material Selection

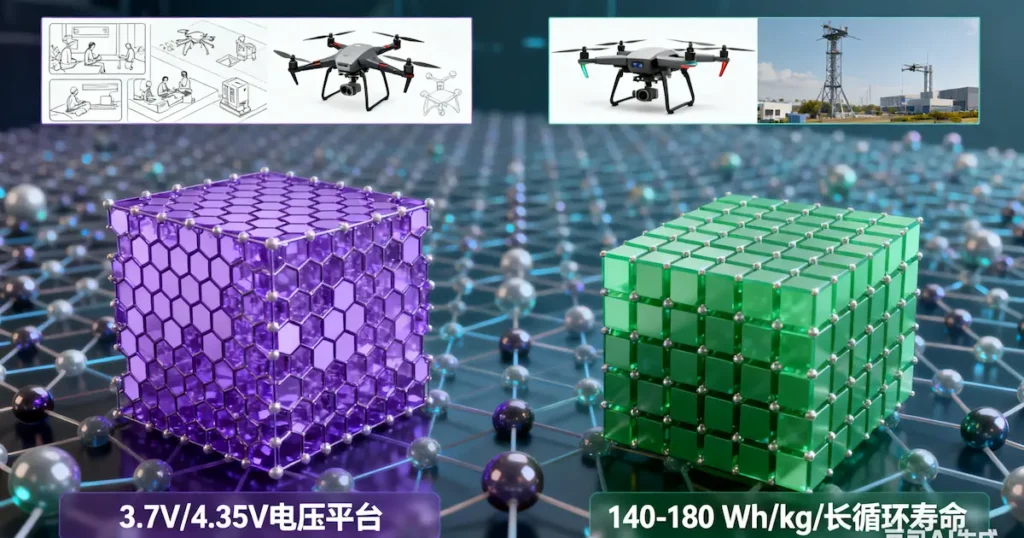

UAV power batteries primarily utilize lithium cobalt oxide (LiCoO₂) cathode materials, featuring a nominal voltage of 3.7V and a fully charged voltage reaching 4.2V or 4.35V. Lithium cobalt oxide delivers outstanding energy density performance due to its high-voltage platform and superior tap density.

For specialized applications, such as industrial drones requiring high safety standards, lithium iron phosphate (LFP) cathode materials are also employed. Although their energy density is lower (140-180 Wh/kg), they offer superior thermal stability and extended cycle life.

Cell Structure and Manufacturing Processes

Consumer-grade drones predominantly utilize pouch cell structures, packaged in aluminum-plastic film. This lightweight design allows for customizable shapes, enabling batteries to better accommodate internal space constraints while delivering sufficient power output.

High-end drones and industrial applications favor cylindrical cells (e.g., 18650, 21700) due to their superior structural strength, enhanced thermal management capabilities, and support for higher sustained discharge currents.

II. Key Performance Parameters and Technical Specifications

Energy Density and Endurance Performance

Energy density serves as the core metric for evaluating battery performance, directly determining a drone’s operational endurance. Currently, commercial drone batteries predominantly operate within an energy density range of 200–280 Wh/kg.

In 2024, the Dalian Institute of Chemical Physics, Chinese Academy of Sciences, developed a high-energy-density battery achieving a breakthrough of 400 Wh/kg, extending drone flight times by 20%-40%. This battery utilizes a high-nickel ternary cathode and a silicon-carbon composite anode, optimizing capacity matching between electrodes to achieve higher energy storage efficiency.

Discharge Characteristics and Power Output

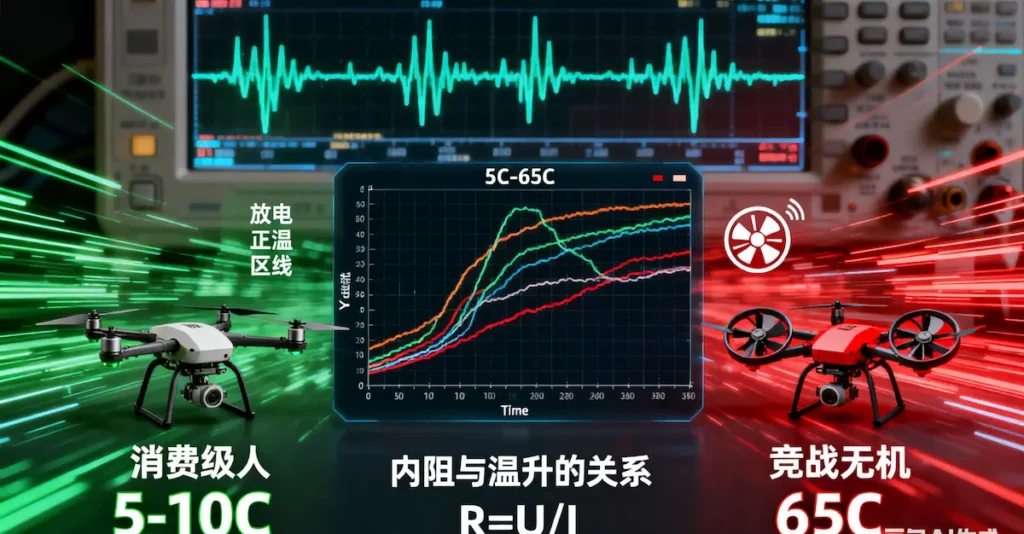

Discharge rate (C-rate) is a critical metric for power batteries, indicating their discharge capability. Consumer-grade multi-rotor drones typically use cells with 5-10C discharge rates, while professional RC models and racing drones require high-rate cells capable of 25C or even 65C.

High-rate discharging generates significant heat, causing battery temperature to rise. Cells with lower internal resistance exhibit stronger discharge capability and lower temperature rise during discharge. Selecting an appropriate discharge rate is crucial for balancing power performance and battery lifespan.

Temperature Characteristics and Environmental Adaptability

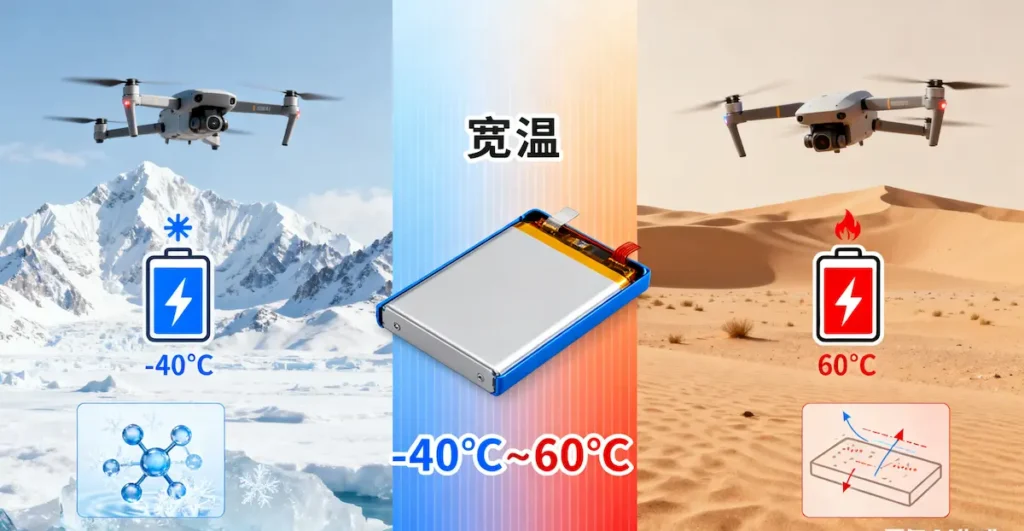

Lithium battery performance is highly dependent on operating temperature. At -3°C, battery discharge capacity can drop by over 20%. The latest wide-temperature-range batteries now operate stably between -40°C and 60°C.

This broad temperature tolerance is achieved through specialized electrolyte formulations incorporating low-freezing-point solvents and functional additives. These significantly lower the freezing point while maintaining ionic conductivity in cold conditions. Concurrently, composite separator technology delivers both high-temperature resistance and low-temperature performance, comprehensively ensuring battery safety.

III. Battery Management System and Safety Design

Core Functions of BMS

The Battery Management System (BMS) serves as the “intelligent brain” of a drone’s power battery, responsible for real-time monitoring of voltage, current, and temperature parameters. A high-quality BMS possesses the following capabilities:

Voltage Balancing: Ensures voltage differences between series-connected cells do not exceed 0.05V

Temperature Monitoring: Activates protective mechanisms during abnormal temperature conditions

Charge/Discharge Control: Prevents overcharging, over-discharging, and overcurrent situations

State Estimation: Accurately calculates remaining capacity and battery health

Safety Protection Mechanisms

Drone battery safety design incorporates multiple protective measures:

- Thermal Runaway Protection: Utilizes thermal breakers, phase-change materials, and heat dissipation channels

- Cell Redundancy Structure: Supports isolation upon single-cell failure

- Multi-level Protection Mechanisms: Physical + electronic level current limiting, temperature limiting, overvoltage shutdown

- Structural Protection: Module shock/pressure resistance and fireproof encapsulation design

IV. Application Considerations and Selection Guide

Capacity and Voltage Configuration

When selecting battery capacity, balance flight endurance with weight increase. Larger capacity batteries offer extended flight times but add weight to the drone, impacting flight performance.

Voltage configuration depends on the drone’s motor and ESC design. Common configurations include:

- 3S Battery: 11.1V nominal voltage, suitable for small consumer drones

- 4S Battery: 14.8V nominal voltage, delivering stronger power output

- 6S Battery: 22.2V nominal voltage, used in professional and high-performance drones

Brand Selection and Performance Evaluation

Leading drone battery brands include Tattu, Rainbow, and HobbyKing. When selecting batteries, consider the following:

- Prioritize products from reputable brands purchased through official channels to avoid capacity mislabeling

- Focus on user-verified performance data rather than relying solely on nominal specifications

- Ensure compatibility between the battery and the drone, including proper interface matching

V. Usage, Maintenance, and Lifespan Management

Charging Practices

Using the original or compatible charger is critical. Mismatched chargers may cause overcharging, fires, or other serious accidents. During charging, place the battery and charger on a flat surface away from flammable materials and monitor the charging process.

Balance charging ensures voltage equilibrium among series-connected cells, extending the overall lifespan of the battery pack. It is recommended to use balance charging mode for every charge cycle, especially for high-series-count battery packs.

Temperature Management

Battery operating and storage temperatures directly impact performance and lifespan. The ideal operating range is 15-25°C (59-77°F), and storage should also be maintained within 15-25°C (59-77°F).

In cold environments, preheat the battery before use to prevent sudden capacity drops and voltage sag caused by low temperatures. In hot conditions, ensure adequate heat dissipation to avoid performance degradation and safety risks due to overheating.

Lifespan Extension Strategies

Lithium batteries typically achieve over 300 cycles (capacity retention below 80%). Key measures to extend battery life include:

- Avoid deep discharges; maintain usage within the 20%-80% charge range

- Prevent high-temperature storage, especially in fully charged states

- Perform regular balancing maintenance to ensure consistent cell voltages

- Store at moderate charge levels (50%-60%) for long-term preservation, with periodic recharge checks

VI. Future Development Trends

Technological Innovation Directions

UAV power battery technology is advancing in the following directions:

- Higher Energy Density: Achieving a target of 500 Wh/kg through technologies such as silicon-carbon anodes and solid-state electrolytes

- Faster Charging Speed: Developing battery systems supporting 6C or higher fast charging to reduce charging time

- Wider Operating Temperature Range: Adapting to application demands spanning -40°C to 60°C or broader temperature ranges

Intelligent Management: Integrating more advanced BMS systems to enable state prediction and fault early warning

Material System Evolution

Solid-state battery technology is considered a key direction for next-generation power batteries, offering energy densities of 300-400 Wh/kg while significantly enhancing safety. Silicon-carbon composite anode materials are also advancing rapidly, with projected energy density improvements to 280-350 Wh/kg.

Power lithium-ion battery technology for drones is a multidisciplinary field encompassing electrochemistry, materials science, thermal management, and electronic control systems. Selecting the appropriate power battery requires comprehensive consideration of energy density, power characteristics, safety performance, and cost factors.

As lithium battery technology engineers, we recommend users choose batteries with specifications suited to their specific application scenarios, adhere to proper usage and maintenance practices, and always prioritize safety. With technological advancements, future drone power batteries will deliver extended flight durations, faster charging speeds, and broader operating temperature ranges, further expanding the application scope of unmanned aerial vehicles.

Proper battery selection and usage habits not only enhance the flying experience but also significantly extend battery lifespan while reducing overall operating costs. Users are advised to procure reliable battery products from authorized channels and conduct regular battery condition checks to ensure flight safety.