Working Principle of Cylindrical Lithium Battery Caps

As the “brain” of the battery safety system, the cap assembly ensures the safety performance of cylindrical lithium batteries under abnormal operating conditions through multi-level protection mechanisms.

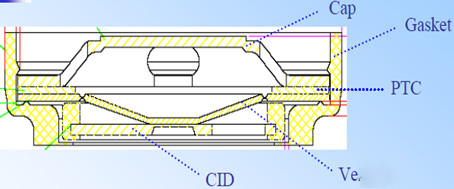

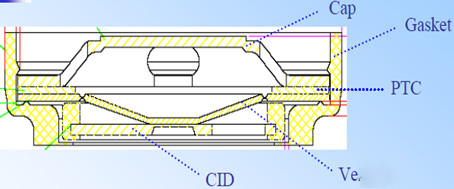

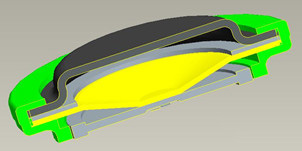

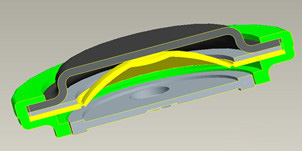

In the structural design of cylindrical lithium batteries, the cap assembly is the core component guaranteeing battery safety. It not only serves as the positive and negative electrode terminals but also integrates multiple safety protection functions. This seemingly simple metal component is actually a sophisticated safety system capable of promptly cutting off current and releasing internal pressure when battery abnormalities occur.

As lithium battery engineers, we must deeply understand the working principle of cylindrical lithium battery caps. This not only concerns battery safety performance but also directly impacts the reliability design of the entire battery system.

I. Core Functions and Composition of Lithium Battery Caps

Cylindrical lithium battery caps serve as composite components integrating electrical, thermal, and mechanical protection. Their primary functions include:

- Current Conduction: Functioning as the positive or negative terminal lead, providing a low-resistance electrical pathway

- Thermal Protection: Utilizing PTC (Positive Temperature Coefficient thermistor) to interrupt the circuit during overheating

- Overcurrent Protection: Permanently disconnects the circuit via a CID (Current Interrupt Device) when internal pressure becomes abnormal

- Pressure Relief Protection: The Vent (explosion relief valve) ruptures under extreme pressure to prevent battery explosion

- Sealing Function: Prevents moisture and gas ingress while inhibiting electrolyte evaporation, maintaining a stable internal battery environment

These functions work synergistically to form a multi-layered safety protection system, ensuring battery reliability during normal operation and safety under abnormal conditions.

II. Protection Mechanism of Cylindrical Lithium Battery Caps

Normal Operating Conditions

Under normal operation, current flows smoothly through the internal conductive pathways of the cap. The PTC element maintains low resistance, the CID device preserves intact weld points, and the vent structure remains sealed. At this stage, the cap functions solely as an efficient current-conducting component, typically exhibiting resistance below 2 mΩ.

Temperature Protection Mechanism

When battery temperature abnormally rises (typically exceeding 80-120°C), the PTC element activates. Its resistance increases sharply with temperature, creating a “switching effect” that limits current flow and prevents thermal runaway. This protection is reversible—once temperature returns to normal, the PTC resistance decreases and the circuit reopens.

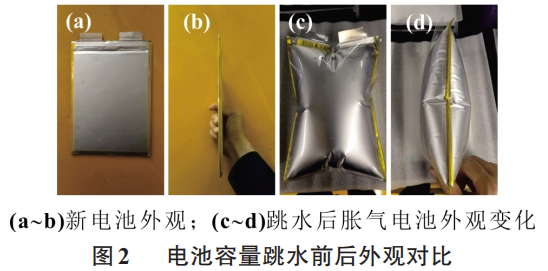

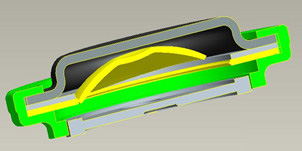

Pressure Protection Mechanism

When abnormal gas generation inside the battery causes pressure to rise, the pressure protection mechanism in the cap activates according to a predetermined sequence:

- Stage 1: When internal pressure reaches the CID activation threshold (typically 0.8–1.8 MPa), the vent structure flips.

- Stage 2: The mechanical displacement caused by the vent flipping severs the CID weld point, permanently interrupting the electrical path.

- Stage 3: If pressure continues to rise and reaches the vent rupture pressure (typically 2.0–3.5 MPa), the vent ruptures completely, allowing high-pressure gas to vent directionally.

This tiered protection mechanism ensures the battery implements orderly protective measures during abnormal conditions, preventing severe safety incidents such as explosions.

III. Key Design Parameters and Engineering Considerations

Pressure Parameter Design

The pressure protection parameters for the cap require precise design:

- Vent Flip Pressure: Typically designed within the range of 0.8–1.8 MPa, adjusted according to the battery system

- CID Disconnect Pressure = Vent Flip Pressure + Equivalent Pressure of CID Solder Joint Tensile Strength

- Equivalent Pressure Conversion: Equivalent Pressure of CID Solder Joint Tensile Strength (MPa) = CID Solder Joint Tensile Strength (N) / Vent Effective Area (mm²)

These parameters must align with the battery system’s gas generation characteristics and casing mechanical strength to ensure the protection mechanism triggers under appropriate pressure conditions.

Material Selection and Process Control

Material selection for the cap assembly is critical:

- – Conductive sheet material requires excellent conductivity and corrosion resistance

- – PTC material demands precise switching temperature and stable performance

- – Sealing material must guarantee long-term sealing reliability

- – Vent film requires precise mechanical properties and rupture characteristics

Manufacturing processes are equally crucial, particularly as CID weld quality directly impacts disconnection pressure accuracy. Strict control of welding parameters and inspection standards is essential.

IV. Lithium Battery Cap Testing, Validation, and Reliability Assurance

Cap assemblies must undergo a series of rigorous validation tests:

- Electrical Performance Testing: Contact resistance, overcurrent capability, PTC characteristics

- Mechanical Performance Testing: Sealing integrity, vibration, shock

- Environmental Testing: Temperature cycling, humidity/heat, salt spray

- Safety Testing: Pressure trigger accuracy, pressure relief effectiveness

These tests ensure the cap functions reliably under extreme conditions, providing sustained safety assurance for the battery.

V. Technological Trends in Lithium Battery Cap Design

As battery energy density continues to increase, cap technology is also evolving:

- Higher precision protection parameters: Adapting to the safety requirements of new battery systems

- Smaller dimensions: Improving internal space utilization within the battery

- Integrated design: Incorporating more protective functions into the cap

- Intelligent monitoring: Integrating temperature and pressure sensors to enable condition monitoring

These innovations will enable future batteries to maintain high energy density while achieving greater safety and reliability.

The cylindrical lithium battery cap is an ingeniously engineered safety protection system, whose multi-layered protective mechanisms embody the “defense-in-depth” security philosophy. From PTC thermal protection to CID current cutoff, and on to vent pressure relief, each tier of protection builds upon and reinforces the preceding one.

As lithium battery engineers, we must not only understand the cap’s operational principles but also deeply grasp the relationship between its design parameters and battery system compatibility. Only through precise design and rigorous quality control can the cap reliably safeguard battery safety under various abnormal conditions, preventing accidents.

With the continuous advancement of battery technology, cap design will also evolve, providing safer and more reliable power assurance for new energy applications.